Manufacturing methods of tungsten-titanium alloy target billet and target material

A technology of tungsten-titanium alloy and manufacturing method, which is applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of unreachable tungsten-titanium alloy target, high hardness value, prone to cracks, etc. Achieve high density, reduce material waste, and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] As described in the background technology, the hardness value of the tungsten-titanium alloy target blanks obtained in the prior art is relatively high, and cracks are prone to appear, which usually cannot meet the requirements of the tungsten-titanium alloy target materials used in semiconductor integrated circuits and solar cells.

[0029] The inventor determined after a long period of unremitting assiduous research that the parameters of the vacuum hot-pressing sintering process play a decisive factor in the performance of the final tungsten-titanium alloy target blank. Various parameters of the target blank, and then control the parameters of the vacuum hot pressing sintering process to obtain a tungsten-titanium alloy target blank that meets the requirements.

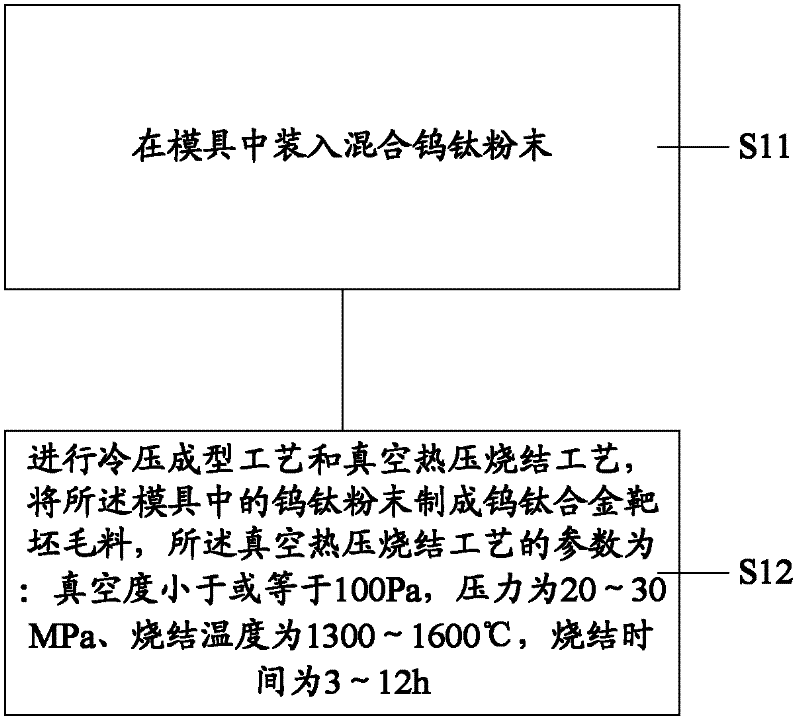

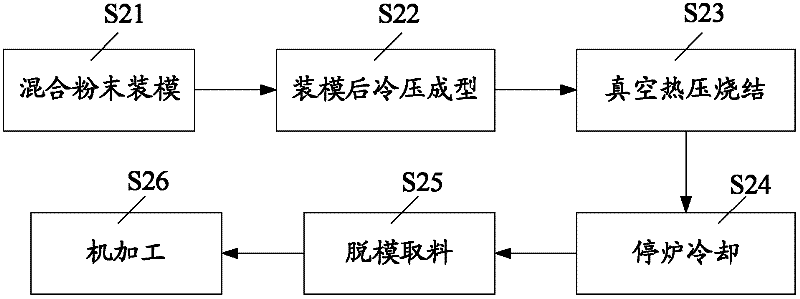

[0030] See figure 1 , figure 1 It is a flow chart of the manufacturing method of the tungsten-titanium alloy target blank according to the embodiment of the present invention, such as figure 1 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com