Method for controlling speed regulation of isothermal extrusion of industrial aluminum profiles for transportation

A technology of isothermal extrusion and transportation, applied in metal extrusion control equipment, metal extrusion, manufacturing tools, etc., can solve the problem of large extrusion deformation, difficult temperature gradient of aluminum rod, mesh distortion in simulation process, etc. problems, to achieve the effect of uniform performance indicators, reduced labor intensity of workers, and reduced extrusion defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

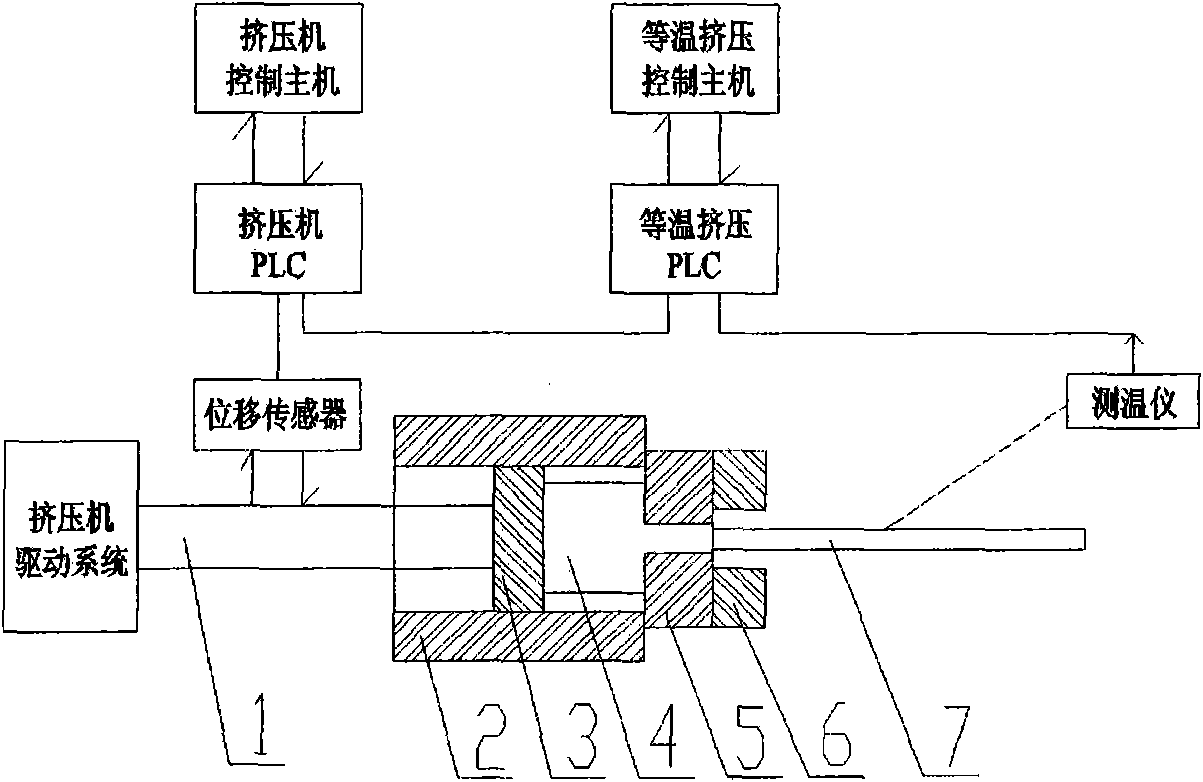

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Isothermal extrusion of high weldability 6xxx series aluminum alloy profiles for refrigerated containers

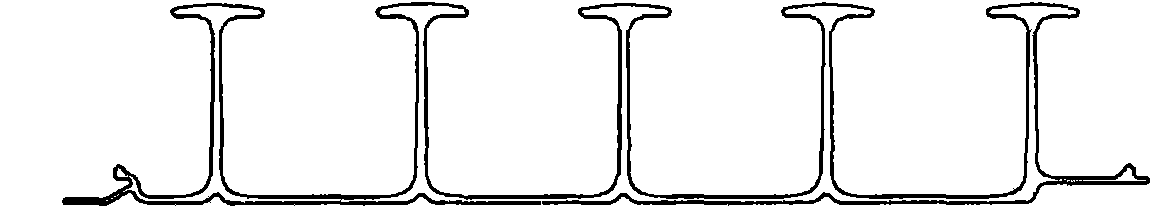

[0028] The aluminum alloy grade is AA6061, the mold model is B1136, the overall dimensions are 340mm (width)×65mm (height)×(2.2~3.2)mm (wall thickness), and the extrusion deformation ratio is 32, such as figure 2 .

[0029] The extrusion process parameters are as follows: the temperature of the extrusion barrel is set to 420°C, the heating temperature of the aluminum rod is set to 480°C, the mold heating temperature is 460°C, and the target temperature of the extrusion outlet of the aluminum profile is 520°C.

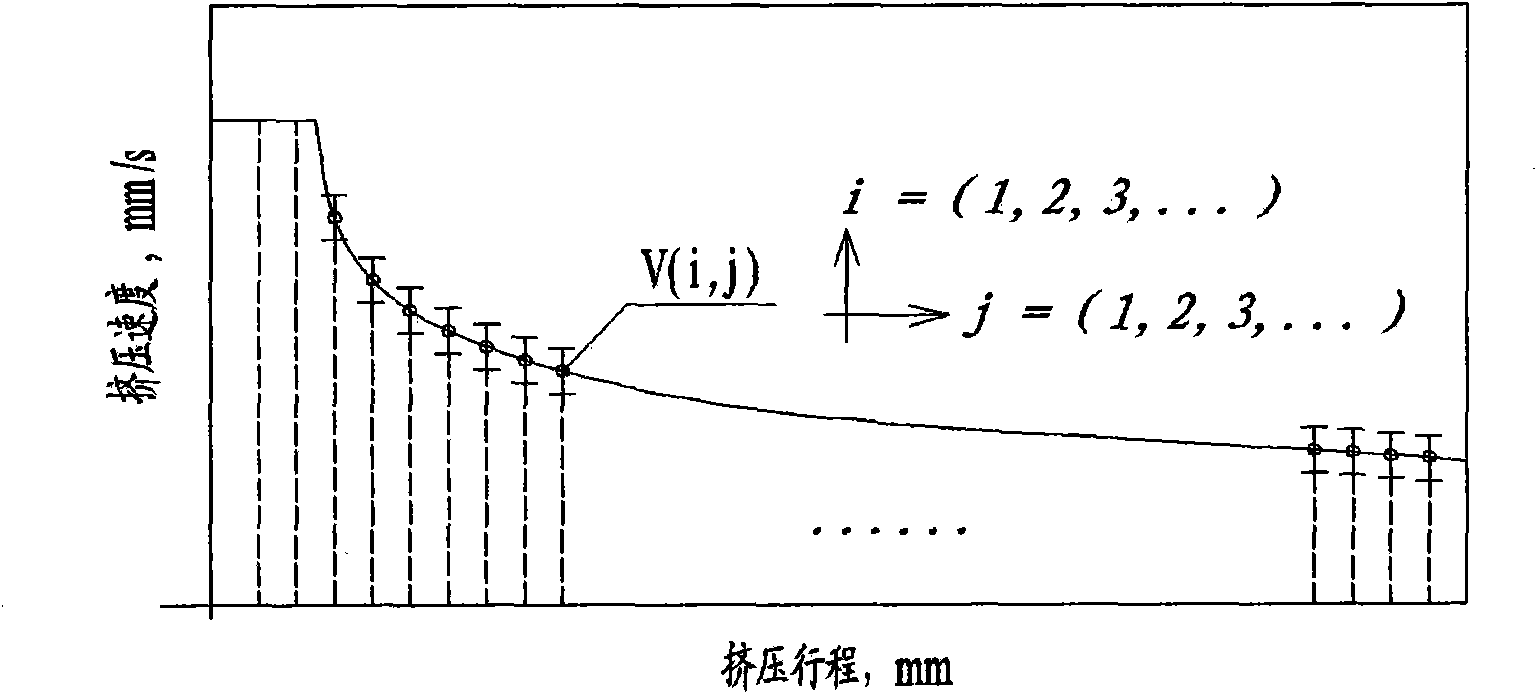

[0030] The length of the AA6061 aluminum alloy cast rod is 1000mm, and the stroke of the extrusion rod is 900mm, which is equally divided into 600 grids, which is equivalent to 600 stroke nodes, and the interval between each stroke node is 1.5mm.

[0031]The initial (maximum) extrusion speed of AA6061-B1136 aluminum profiles for refrigerated con...

Embodiment 2

[0041] Example 2: Isothermal Extrusion of High-performance 5xxx Series Aluminum Alloy Plate Profiles with Ribs for High-speed Ships

[0042] The aluminum alloy grade is 5A30, the mold model is B2819, the overall dimensions are 280mm (width) × 55mm (height) × 4.5mm (wall thickness), and the extrusion deformation ratio is 36 ( Figure 5 ).

[0043] The extrusion process parameters are as follows: the temperature of the extrusion barrel is set to 420°C, the heating temperature of the aluminum rod is set to 450°C, the mold heating temperature is 440°C, and the target temperature of the extrusion outlet of the aluminum profile is 500°C.

[0044] The length of the 5A30 aluminum alloy casting rod is 800mm, and the stroke of the extruded rod is 700mm, which is equally divided into 350 grids and 350 stroke nodes, and the interval between each stroke node is 2mm.

[0045] The initial (maximum) extrusion speed of 5A30-B2819 aluminum profiles for high-speed ships is 2.05mm / s, which comes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com