Integrated touch control module, manufacturing method thereof and touch display device

A touch module and manufacturing method technology, applied in the fields of instruments, optics, electrical digital data processing, etc., can solve problems such as the display of macula in touch display devices, and achieve the effects of good flatness and avoiding deformation and warping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] As mentioned in the background section, the integrated touch module and touch display device formed by the existing full lamination technology are prone to display macular problems.

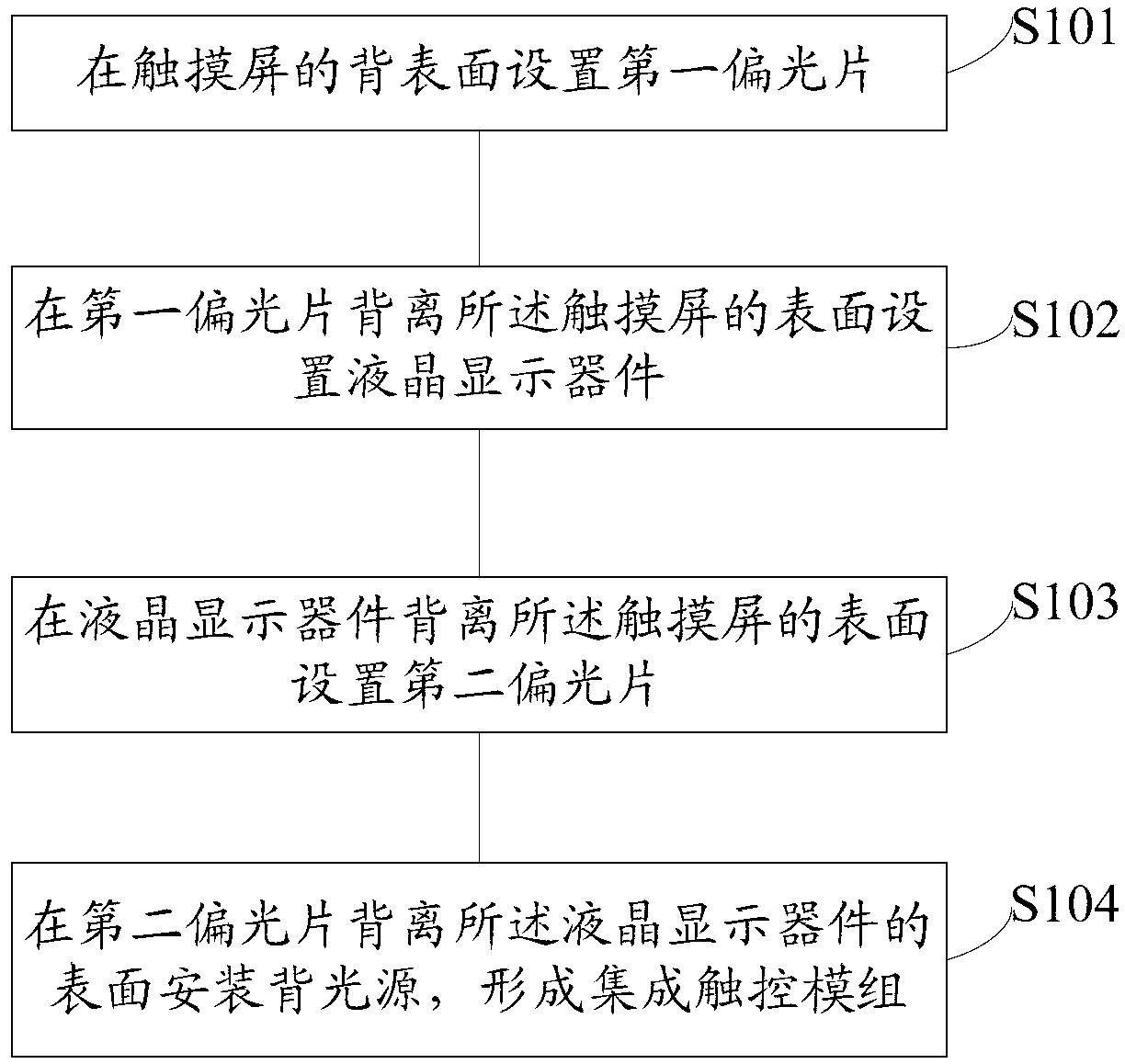

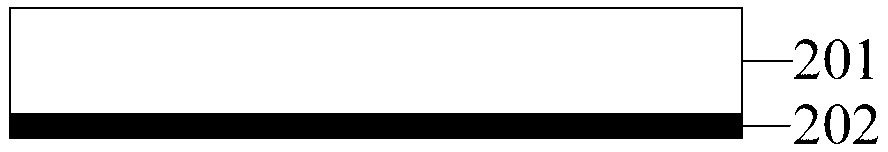

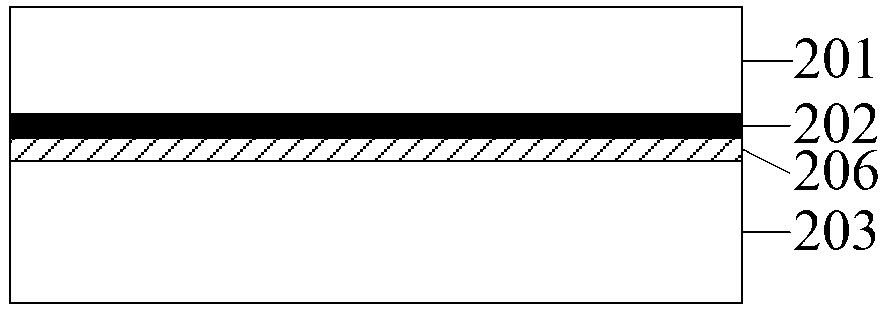

[0023] The existing method of forming an integrated touch module includes: first attaching a polarizer and a lower polarizer to the upper and lower surfaces of the LCD box; then installing a backlight on the surface of the lower polarizer to form an LCD module; The LCD module is fully bonded to the touch screen to form an integrated touch module.

[0024] The inventors found that since the upper and lower surfaces of the LCD box are glass substrates, and since the thermal expansion rate and shrinkage rate of the glass are different from those of the polarizer, the process of attaching the polarizer to the upper and lower surfaces of the LCD box , Affected by the temperature and humidity of the outside world, due to the different degrees of expansion or contraction of the glass and the pola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com