Press polishing method of plastered mesh cloth of inner wall

A construction method and technology of mesh cloth, which is applied in the direction of construction and building construction, can solve the problems of poor flatness and verticality control, difficulty in controlling large-area wall surfaces, and construction limitations, etc., to achieve increased Effect of construction direct cost, unique surface texture and anti-cracking, workload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Materials:

[0025] Construction mortar, alkali-resistant grid cloth, concrete interface agent.

[0026] Mortar for construction shall meet the sand requirements in GB / T 14684-2001 "Standard for Sand for Construction". (Cement: cement not lower than grade 32.5; sand: medium sand with an average particle size of 0.35-0.5mm; water: drinking water.)

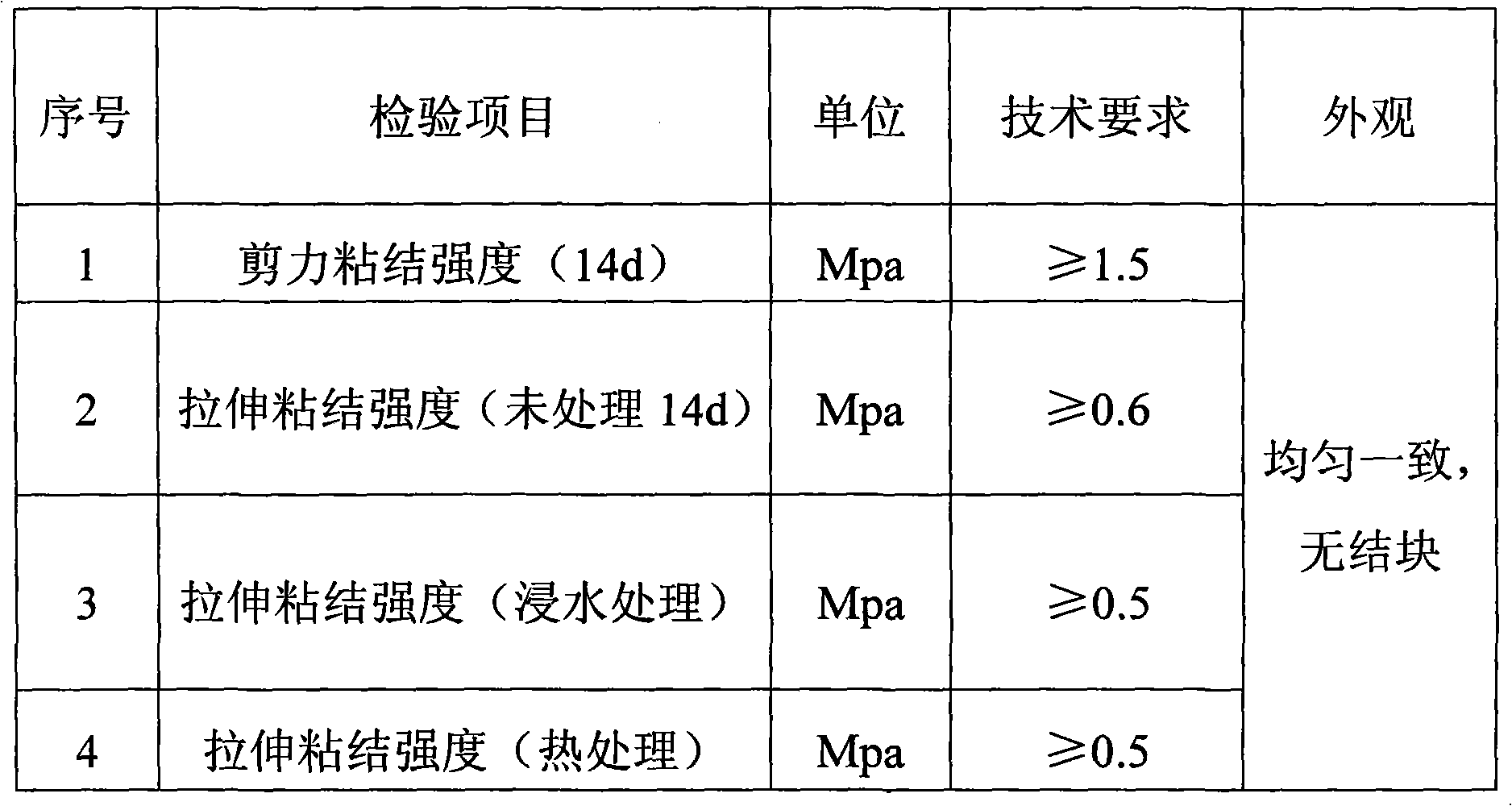

[0027] The material performance of alkali-resistant glass fiber mesh cloth refers to the requirements of JGJ 144-2004 in "Technical Specifications for External Wall Insulation System". The main performance indicators are shown in the table below

[0028] Glass fiber mesh performance index

[0029] serial number

Test items

unit

technical indicators

1

Mass per unit area

g / m2

≥160

2

Breaking strength (warp, weft)

N / 50mm

≥1500

3

Alkali-resistant fracture strength retention rate (warp, weft)

%

≥50

4

Fracture strain (longitude, lat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brushing thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com