Cutting method of crystal blank

A cutting method and blank technology, which is applied in the field of cutting large-size sapphire crystal blanks, can solve the problems of short service life of saw bands, low crystal size accuracy, poor flatness, etc., and achieve simple cutting process, convenient operation, and reduced costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

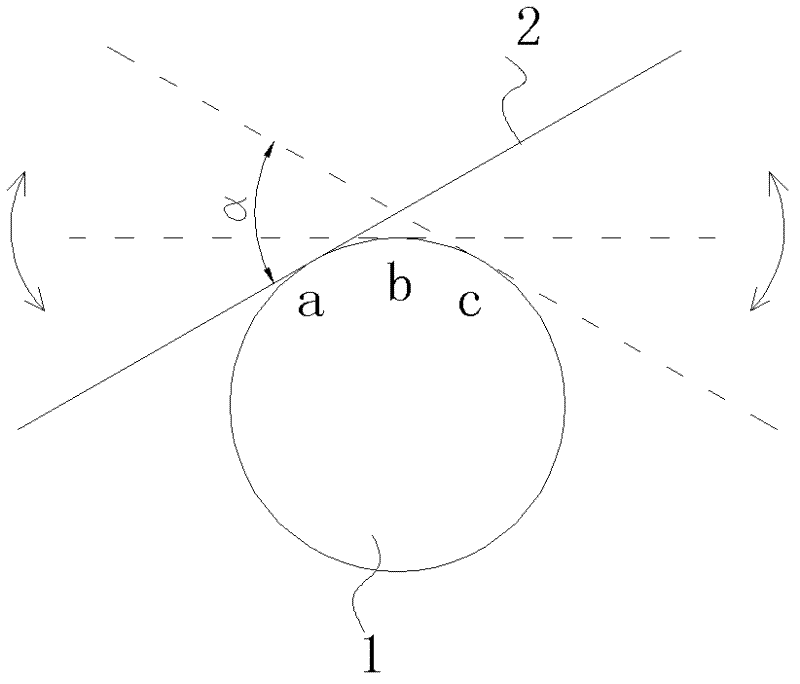

Method used

Image

Examples

Embodiment 1

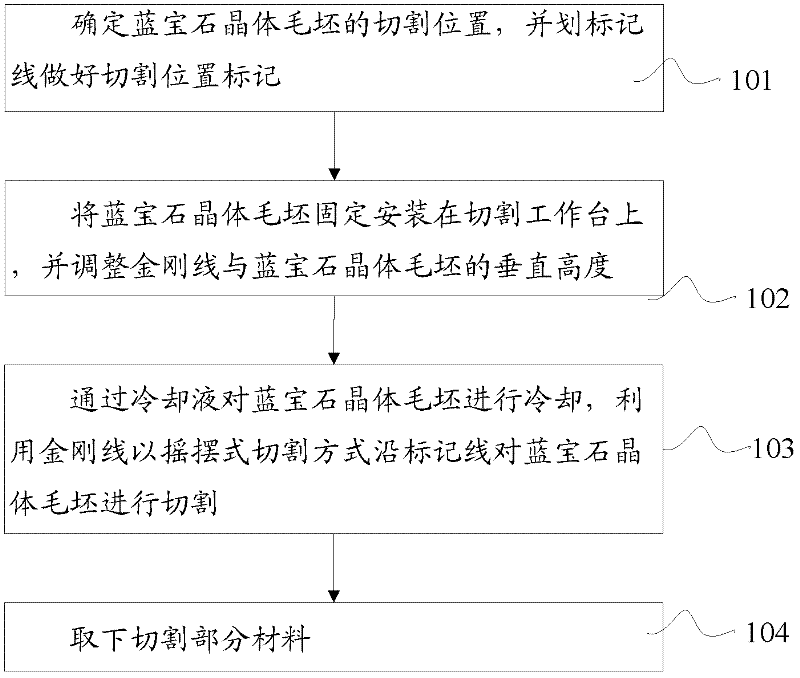

[0040] The specific operation process for cutting 85Kg sapphire crystal ingot is as follows:

[0041] (1) Choose a diamond wire with a diameter of 0.25-0.35mm, and adjust the wire wheel, tension wheel, and guide wheel installed on the cutting machine to ensure that the tension of the diamond wire is evenly distributed.

[0042] (2) Preparation of cooling liquid: the cooling liquid is preferably a special cutting fluid for sapphire, and is prepared with a volume ratio of cutting fluid and water 1: (15-30).

[0043] (3) Determine the area to be cut of the sapphire crystal ingot: first roughly cut out the C surface of the sapphire crystal ingot, and by observing the surface of the grown sapphire crystal ingot, initially determine the C direction, and draw a marking line with a marker pen to mark the cutting position. Determine the area to be cut.

[0044] (4) Install and fix the sapphire crystal blank: paste the marked sapphire crystal ingot on the workpiece plate with AB glue (...

Embodiment 2

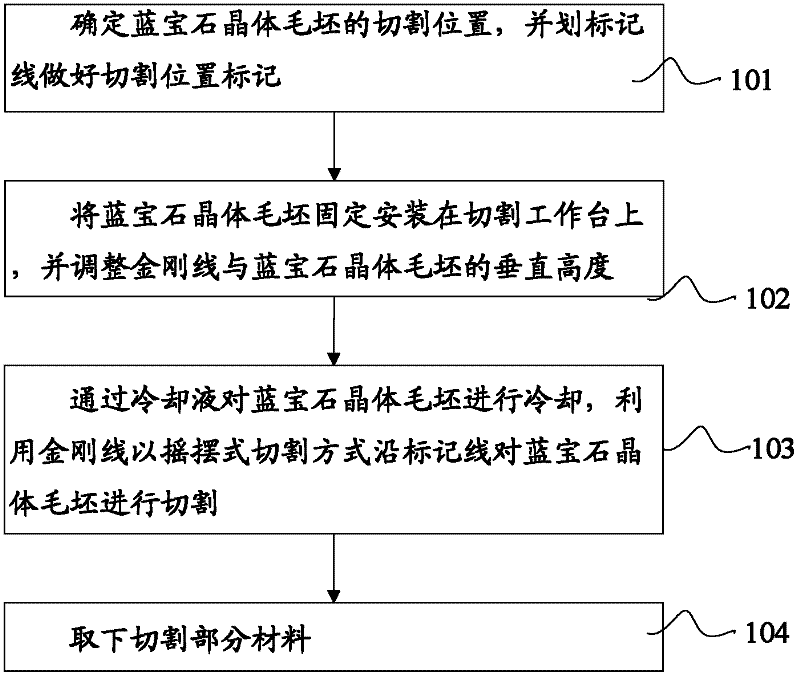

[0053] The specific operation process for cutting the end face of the sapphire crystal rod is as follows:

[0054] (1) Choose a diamond wire with a diameter of 0.25-0.35mm, and adjust the wire wheel, tension wheel, and guide wheel installed on the cutting machine to ensure that the tension of the diamond wire is evenly distributed.

[0055] (2) Preparation of cooling liquid: the cooling liquid is preferably a special cutting fluid for sapphire, and is prepared at a volume ratio of cutting fluid to water 1: (15-30).

[0056] (3) Determine the end face of the sapphire ingot to be cut: observe the internal quality of the ingot after the rod is set, determine the available area of the ingot, mark the cutting position with a marker pen, and determine the end face to be cut.

[0057] (4) Install and fix the sapphire crystal ingot: Paste the marked sapphire crystal ingot on the workpiece plate with AB glue (two-component glue) or Q glue, and then fix the workpiece plate on the cutt...

Embodiment 3

[0066] The remaining crystal material after cutting the sapphire crystal ingot or crystal rod in the above embodiments can be used to process the seed crystal, so as to improve the utilization rate of the crystal and reduce the processing cost.

[0067] The specific operation process of seed crystal processing is as follows:

[0068] (1) Choose a diamond wire with a diameter of 0.25-0.35mm, and adjust the wire wheel, tension wheel, and guide wheel installed on the cutting machine to ensure that the tension of the diamond wire is evenly distributed.

[0069] (2) Preparation of cooling liquid: the cooling liquid is preferably a special cutting fluid for sapphire, and is prepared at a volume ratio of cutting fluid to water 1: (15-30).

[0070] (3) Determine the end face of the seed crystal to be cut: determine the width of the seed crystal to be cut, draw a marking line on the remaining crystal material with a marker pen to mark the cutting position, and determine the end face to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com