Large-diameter main reflecting mirror

A main mirror and large-caliber technology, applied in installation, optics, instruments, etc., can solve problems affecting camera quality, launch costs, manpower and material resources consumption, and easy changes in mirror surface shape, so as to reduce the peak-to-valley value of the mirror surface, The maximum deformation displacement is reduced, and the effect of light weight is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

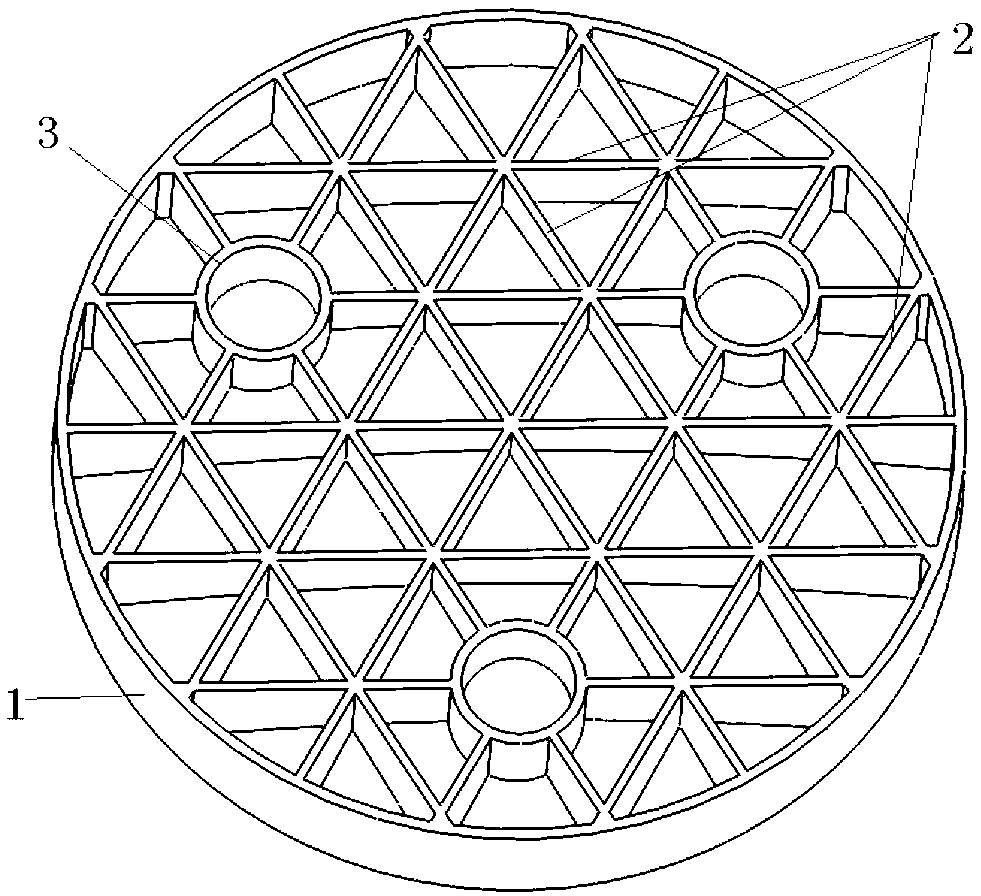

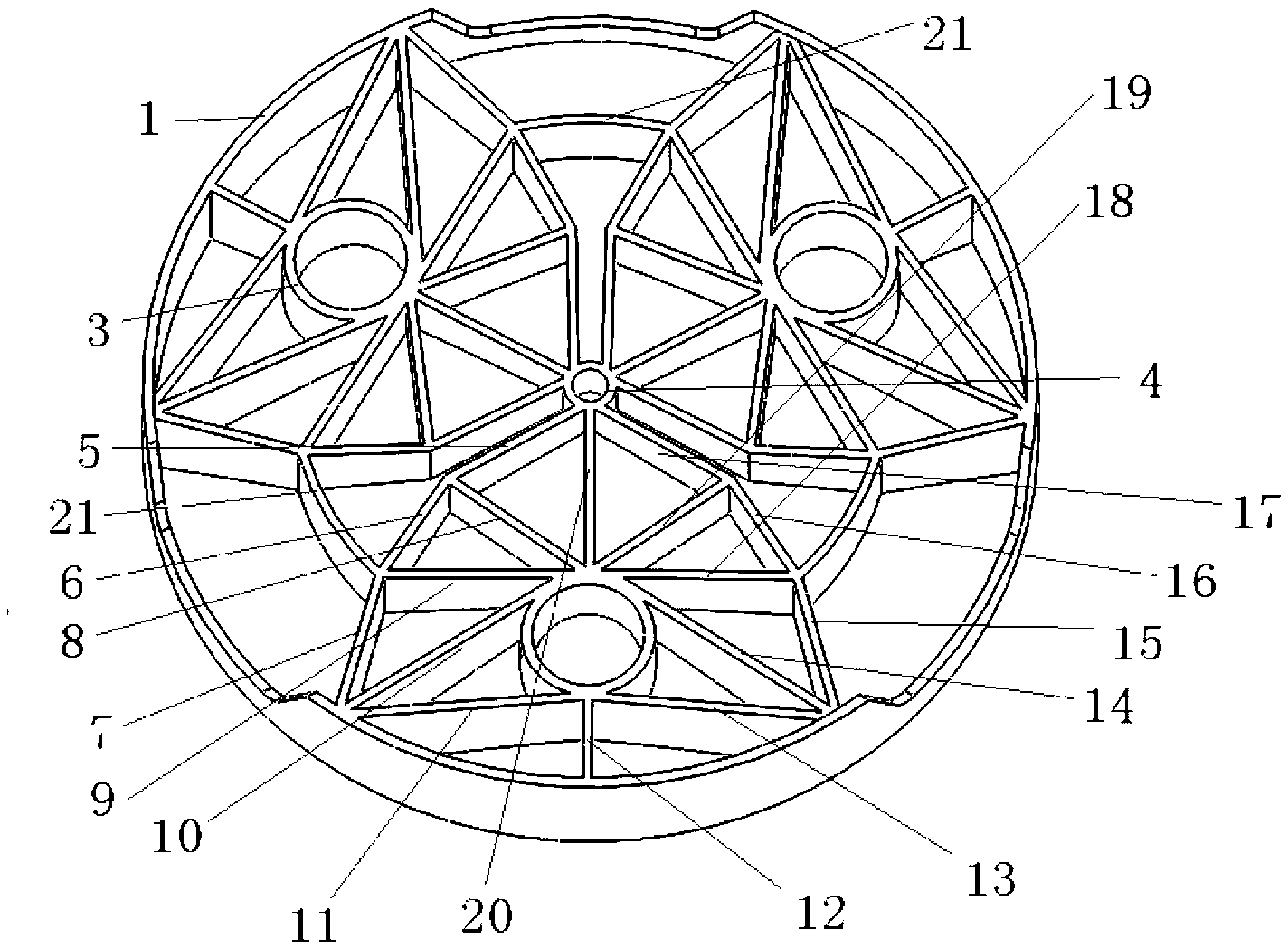

[0021] Such as figure 1 , figure 2 As shown, the present invention includes a mirror surface, a back plate, an outer wall arranged on the outside of the back plate, three circumferentially evenly distributed installation hole walls (3) arranged on the back plate, an outer wall (1) and an installation hole wall (3) ) between multiple reinforced walls (2), multiple reinforced walls (2) including a central hole wall arranged in the center of the back plate, three reinforced wall units uniformly distributed along the circumference of the central hole wall, and three reinforced wall units connected of the three connecting walls.

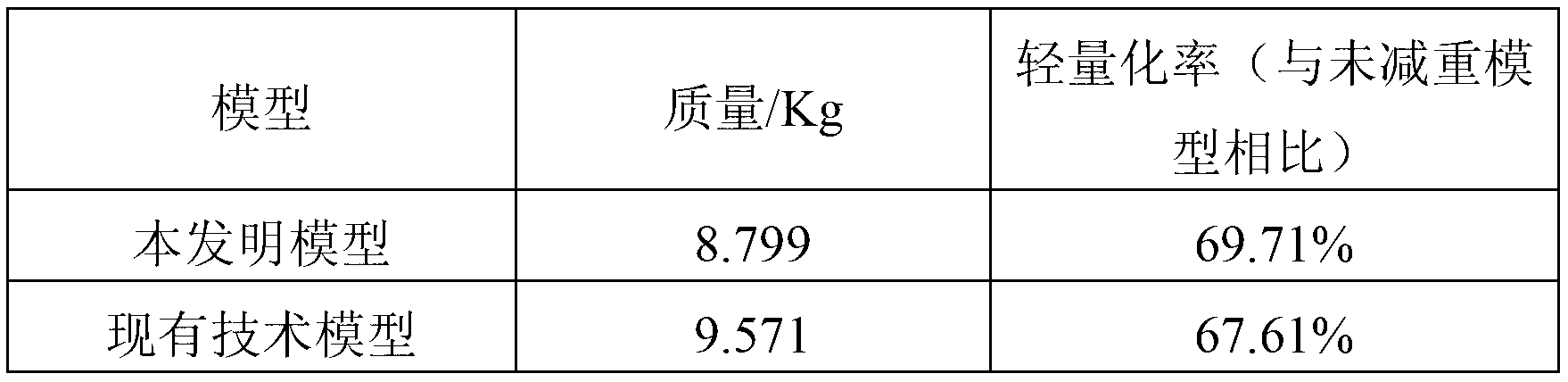

[0022] Such as figure 1 , figure 2 As shown, the diameter of the main mirror of the two models is 500mm, and both use silicon carbide material. (Material parameters: density 3050kg / m 3 , elastic modulus 280Gpa, Poisson's ratio 0.142)

[0023] Compare the inventive model ( figure 2 ) with the state-of-the-art model ( figure 1 ) lightweight perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com