Thermal-insulation three-dimensional hollow composite board and application thereof

A technology of three-dimensional hollow and composite panels, which is applied in the direction of synthetic resin layered products, layered products, transportation and packaging, etc., can solve the problems of limited application range, thermal insulation performance of three-dimensional hollow composite materials cannot meet technical requirements, etc., and achieve cost Low, excellent promotion value, good effect of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

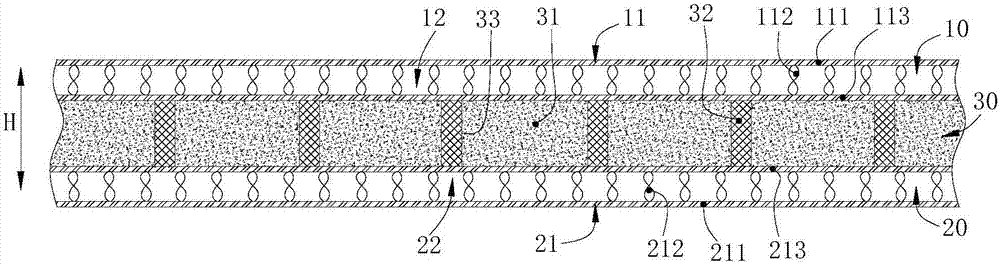

[0032] See figure 1 ,in figure 1 The appropriately marked arrow H indicates the thickness direction of the core layer, which is also the thickness direction of the insulated three-dimensional hollow composite panel.

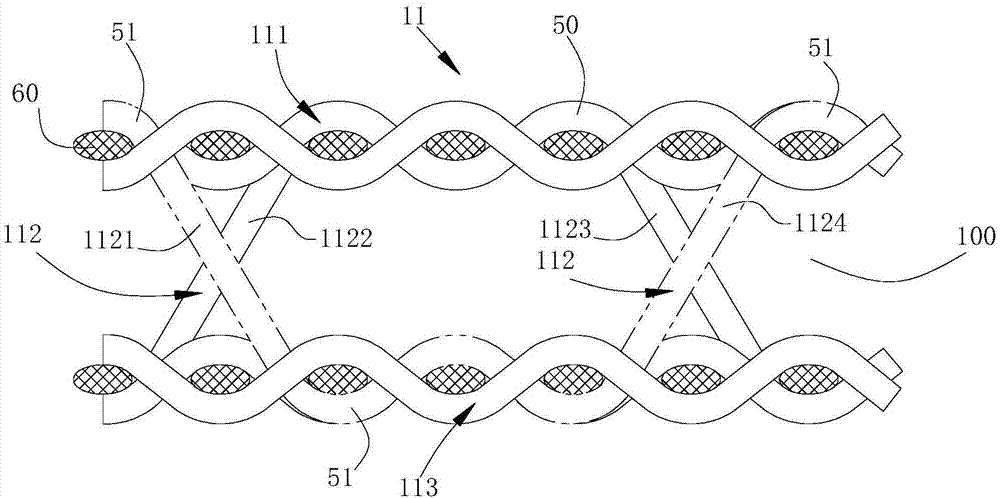

[0033] The insulated three-dimensional hollow composite panel is a sandwich structure, including a core layer 30 and reinforcement layers located on both sides of the thickness direction H of the core layer 30. The core layer 30 includes a foam layer 31 and a foam layer 31 made of resin A. Into the reinforced rib 32. For the convenience of description, the reinforcement layers located on both sides of the core layer 30 are respectively referred to as the first reinforcement layer 10 and the second reinforcement layer 20. Both the first reinforcement layer 10 and the second reinforcement layer 20 are made of three-dimensional hollow composite materials. The resin B is compounded to the foam layer 31, and the reinforcing ribs 32 penetrate the foam layer 31 and are con...

Embodiment 2

[0048] This embodiment is basically the same as embodiment 1, and the difference lies in:

[0049] In this embodiment, the components of resin A and resin B are the same, both are unsaturated polyester resins, and are the same as the resin used in the resin matrix.

[0050] The diameter of the rib holes is 5mm, the rib holes are arranged in a matrix, and the center distance between adjacent rib holes is 25mm.

[0051] The thickness of each reinforcement layer in this embodiment is 15mm, and the areal density is 3kg / m 3 (The surface density of a traditional skin of equal thickness is 30kg / m 2 ). The resin matrix in the three-dimensional hollow composite material is an unsaturated polyester resin, and the mass ratio of the resin matrix to the reinforcement is 10:8.

[0052] The foam layer in the core layer is polyurethane foam, the thickness of the core layer is 20mm, and the surface density is: 120kg / m 3 , The reinforcing rib is made of unsaturated polyester resin, and the reinforcing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com