Flagstone positioning clamp and processing method therefor

A technology for positioning jigs and slates, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems that the flatness consistency is not guaranteed, and the human hand cannot be positioned and does not move, so as to achieve a beautiful appearance, Good flatness and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

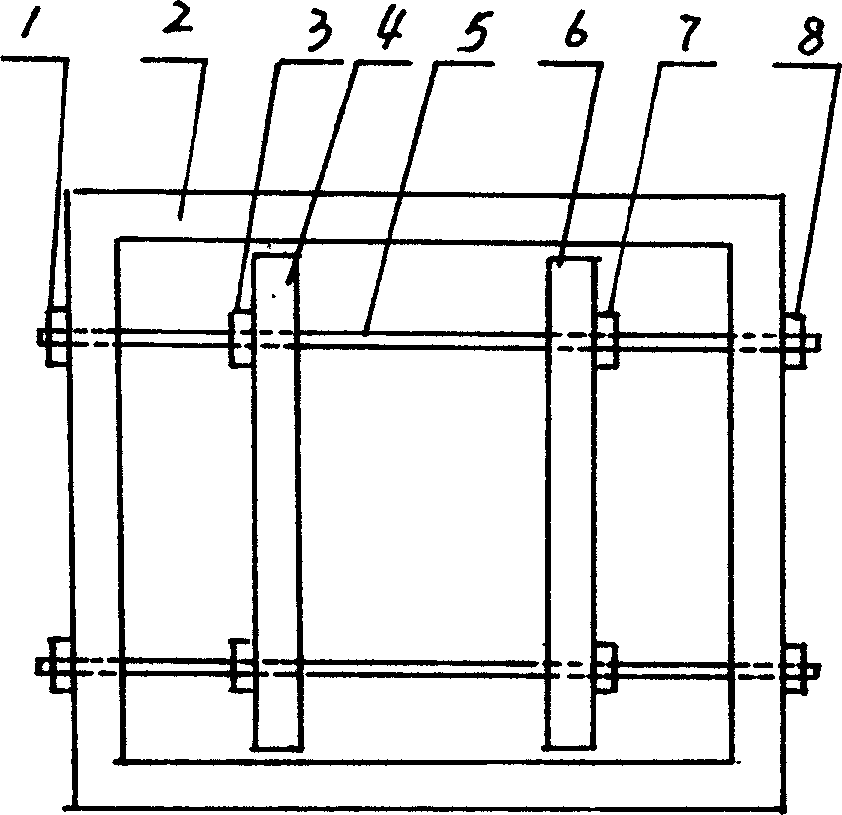

[0009] Embodiment 1: with reference to attached figure 1 . The slate positioning fixture, the rectangular frame 2 adopts wood or plastics or resin plate or bakelite to be processed into a rectangular frame according to the prior art, and the horizontal and vertical directions in the rectangular frame are provided with slate positioning bolts to tighten the structure. The locking structure of the positioning bolts of the slate is a well-tac-toe movable locking structure, with the screw rod 5 in the horizontal direction and the two splints 4 and 6 in the longitudinal direction, and the distance between the two splints 4 and 6 is adjusted by the nuts 3 and 7 on the screw rods. Two screw mandrels 5 pass through the rectangular frame 2, and their two ends are fixed on the rectangular frame by nuts 1 and 8.

Embodiment 2

[0010] Embodiment 2: On the basis of Embodiment 1, the stone slab to be ground in the rectangular frame 2 is clamped by positioning wedges.

Embodiment 3

[0011] Embodiment 3: The processing method of the slate surface, the slate positioning fixture is located on the working table of the drilling, milling, boring and grinding machine, the slope or end surface of the slate to be ground is located in the rectangular frame, and the slate positioning bolts in the rectangular frame are tightened to the structure or positioning wedge Fix and position the stone slab by block, adjust the angle and grinding amount of the grinding head of the drilling, milling, boring and grinding machine according to the angle of the inclined surface or end surface to be processed, start the drilling, milling and boring grinding machine, and the grinding head will automatically move down to touch the stone slab for left and right grinding, until When the set grinding amount is reached, or the grinding head automatically moves down to touch the stone plate, the working table of the drilling, milling and boring grinder moves left and right, forcing the stone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com