Spinning part support type corrugated pipe spinning equipment and forming method

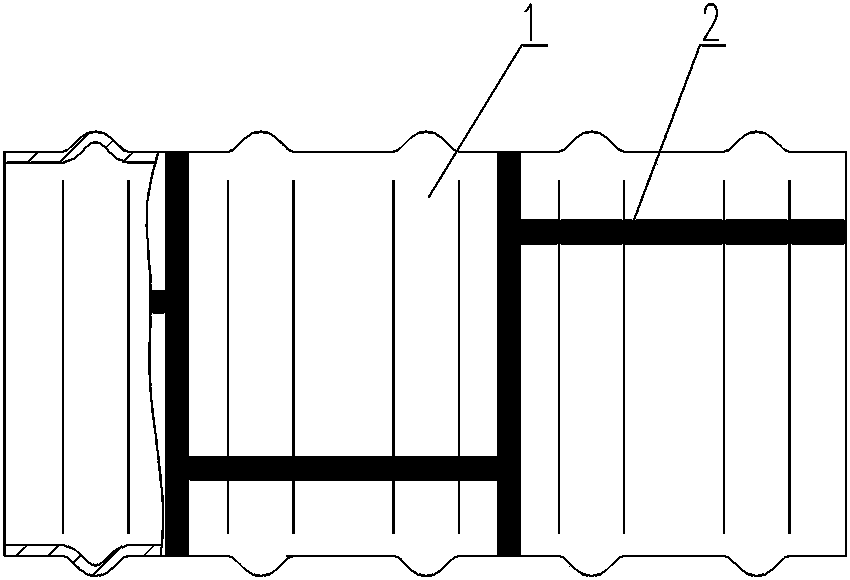

A technology of spinning equipment and forming method, which is applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in guaranteeing the welding quality of tunnel pipes, poor forming accuracy and consistency, and inability to complete bellows processing, etc., to achieve saving Welding material costs and weld inspection costs, high accuracy of corrugation processing, and the effect of reducing the amount of welding seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The material is 5A03 (LF3) long thin-walled pipe, its inner diameter is d=264.6mm, the wall thickness is 3mm, the inner diameter of the trough of the finished corrugated pipe is d=247mm, the outer diameter is D=253mm, and the rounded corner of the corrugated top of the finished corrugated pipe Radius R=13.2mm.

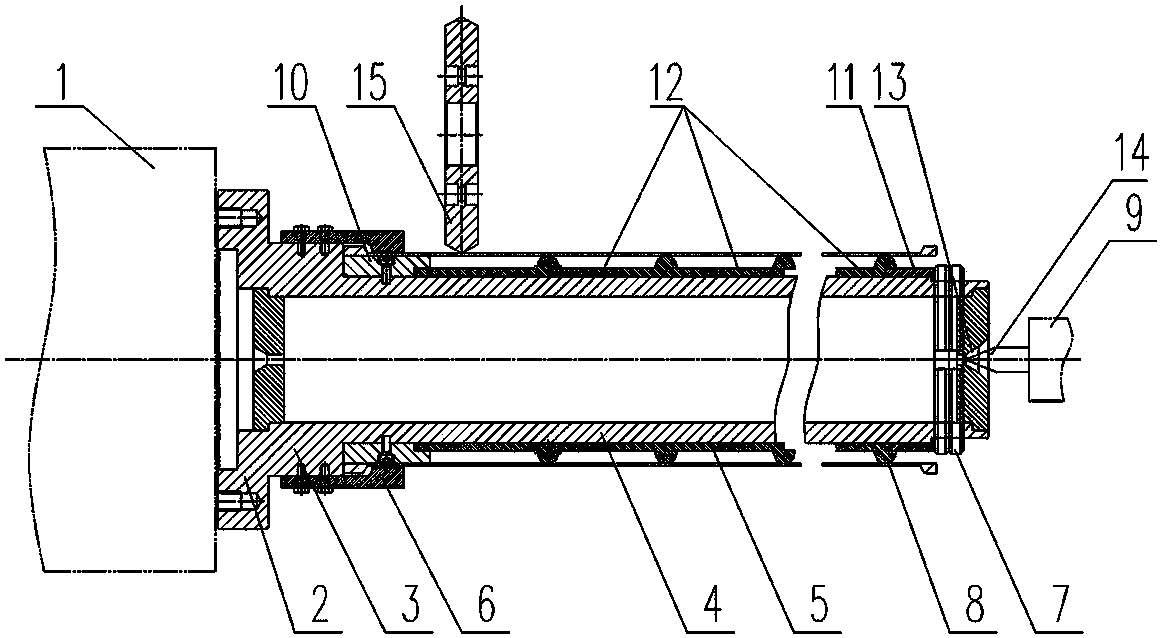

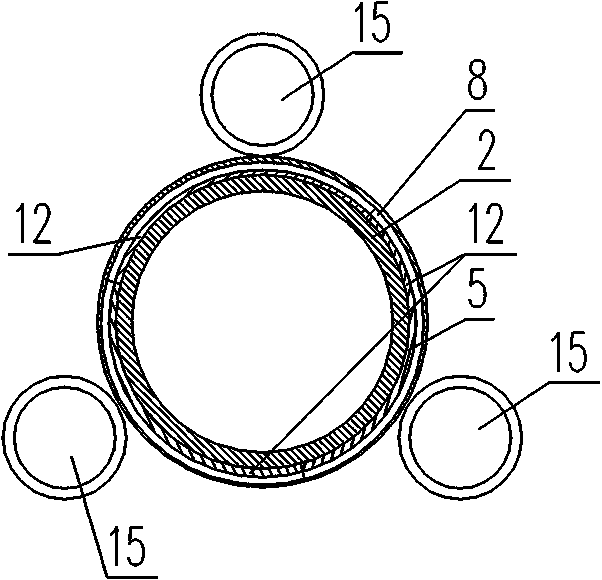

[0032] like figure 2 As shown in the figure, there is a bellows spinning equipment supported by the spinning part, which includes a mandrel 2 connected to the main shaft 1 of the spinning machine. One end of the large-diameter section 3 is provided with a briquetting block 6 on the large-diameter section 3, and a corrugated mold 5 is set on the outside of the small-diameter section 4 of the mandrel 2. One end of the briquetting block 6 is fixed on the large-diameter section 3, and the briquetting block 6 The other end of the mandrel 2 is pressed against the outer surface of the corrugated mold 5, and a plurality of pressure blocks 6 are arranged on the large d...

Embodiment 2

[0042] The material is 5A03 (LF3) long thin-walled pipe, its inner diameter d=264.6mm, wall thickness is 2.7mm, the inner diameter of the wave trough of the finished bellows is d=244.6mm, the outer diameter D=250mm, and the corrugated top of the finished bellows Fillet radius R=16.2mm.

[0043] like figure 2 As shown in the figure, there is a bellows spinning equipment supported by the spinning part, which includes a mandrel 2 connected to the main shaft 1 of the spinning machine. One end of the large-diameter section 3 is provided with a briquetting block 6 on the large-diameter section 3, and a corrugated mold 5 is set on the outside of the small-diameter section 4 of the mandrel 2. One end of the briquetting block 6 is fixed on the large-diameter section 3, and the briquetting block 6 The other end of the mandrel 2 is pressed against the outer surface of the corrugated mold 5, and a plurality of pressure blocks 6 are arranged on the large diameter section 3 of the mandrel...

Embodiment 3

[0053] The material is 5A03 (LF3) long thin-walled pipe, its inner diameter d=264.6mm, wall thickness is 3.5mm, the inner diameter of the wave trough of the finished bellows is d=246mm, the outer diameter D=253mm, and the circle at the top of the wave form of the finished bellows Corner radius R=13.2mm.

[0054] like figure 2 As shown in the figure, there is a bellows spinning equipment supported by the spinning part, which includes a mandrel 2 connected to the main shaft 1 of the spinning machine. One end of the large-diameter section 3 is provided with a briquetting block 6 on the large-diameter section 3, and a corrugated mold 5 is set on the outside of the small-diameter section 4 of the mandrel 2. One end of the briquetting block 6 is fixed on the large-diameter section 3, and the briquetting block 6 The other end of the mandrel 2 is pressed against the outer surface of the corrugated mold 5, and a plurality of pressure blocks 6 are arranged on the large diameter sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com