Preparation method of martensite matrix 1,100-MPa-grade rare earth Q and P steel

A technology of martensite and matrix, applied in the field of martensite matrix 1100MPa rare earth Q&P steel preparation, can solve the problems of high production technology requirements, affecting welding performance, high-strength steel only focusing on strength or plasticity, etc., to achieve good comprehensive mechanical properties , uniform internal structure and controllable casting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

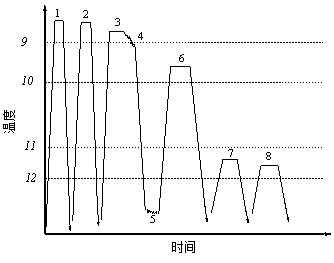

Image

Examples

Embodiment 1

[0046] The material composition and weight percentage used in actual production are C: 0.18%, Si: 0.80%, Mn: 1.70%, Mo: 0.30%, Al: 0.20%, V: 0.05%, Y : 0.01%, P: 0.02%, S≤0.005%, Nb: 0.040%, N≤0.0060%, B: 0.001%, the balance is Fe and unavoidable impurities, the process Contains the following steps:

[0047] (1) Smelting process: according to the composition formula given in the present invention, after batching, it is smelted in a converter, secondary refined in a vacuum furnace, and continuously cast to obtain a slab. The chemical composition and weight percentage of the slab are: C: 0.18%, Si: 0.80%, Mn: 1.70%, Mo: 0.30%, Al: 0.20%, P: 0.02%, S≤0.005%, N≤0.0060 %, the balance is Fe and unavoidable impurities;

[0048] (2) Trace element melting process: Add trace alloy element powder into the arc melting furnace to obtain a secondary cast slab. The chemical composition of the obtained cast slab is as follows: C: 0.18%, Si: 0.80 %, Mn: 1.70%, Mo: 0.30%, Al: 0.20%, V: 0.05%...

Embodiment 2

[0056] The material composition and weight percentage used in actual production are C: 0.18%, Si: 1.10%, Mn: 1.90%, Mo: 0.1%, Al: 0.18%, V: 0.05%, Y : 0.02%, P: 0.03%, S≤0.005%, Nb: 0.050%, N≤0.0060%, B: 0.001%, the balance is Fe and unavoidable impurities, the process Contains the following steps:

[0057] (1) Smelting process: according to the composition formula given in the present invention, after batching, it is smelted in a converter, secondary refined in a vacuum furnace, and continuously cast to obtain a slab. The chemical composition and weight percentage of the slab are: C: 0.18%, Si: 1.10%, Mn: 1.90%, Mo: 0.1%, Al: 0.18%, P: 0.03%, S≤0.005%, N≤0.0060 %, the balance is Fe and unavoidable impurities;

[0058] (2) Trace element melting process: Add trace alloy element powder into the arc melting furnace to obtain a secondary cast slab. The chemical composition of the obtained cast slab is as follows: C: 0.18%, Si: 1.10 %, Mn: 1.90%, Mo: 0.1%, Al: 0.18%, V: 0.05%, Y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com