Column crane mast section rotating assembly tire

A technology of tower cranes and standard joints, which is applied to cranes, auxiliary devices, auxiliary welding equipment, etc., can solve problems affecting product quality, high labor intensity, and low production efficiency, and achieve increased welding difficulty, low labor intensity, and mobile fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

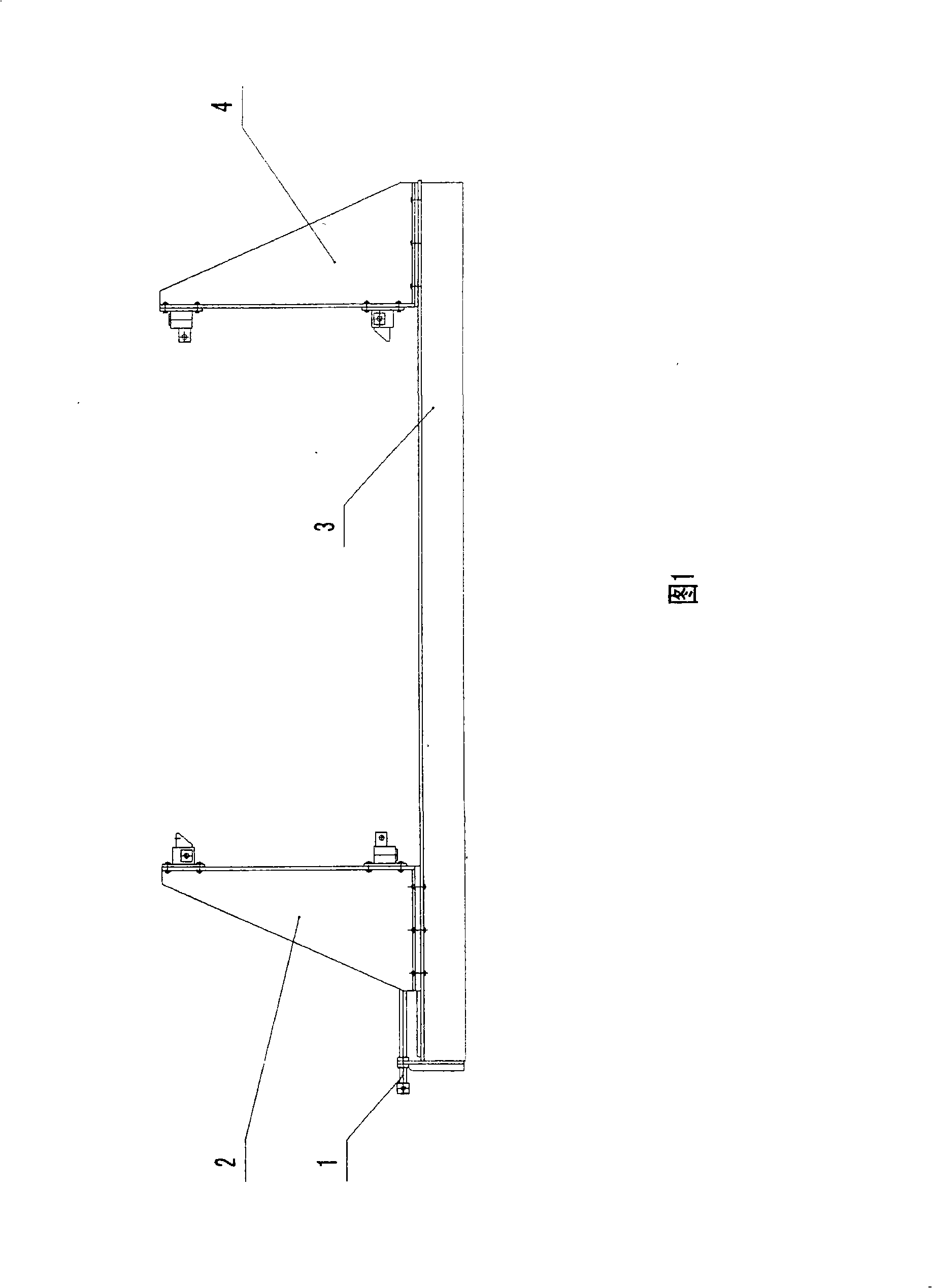

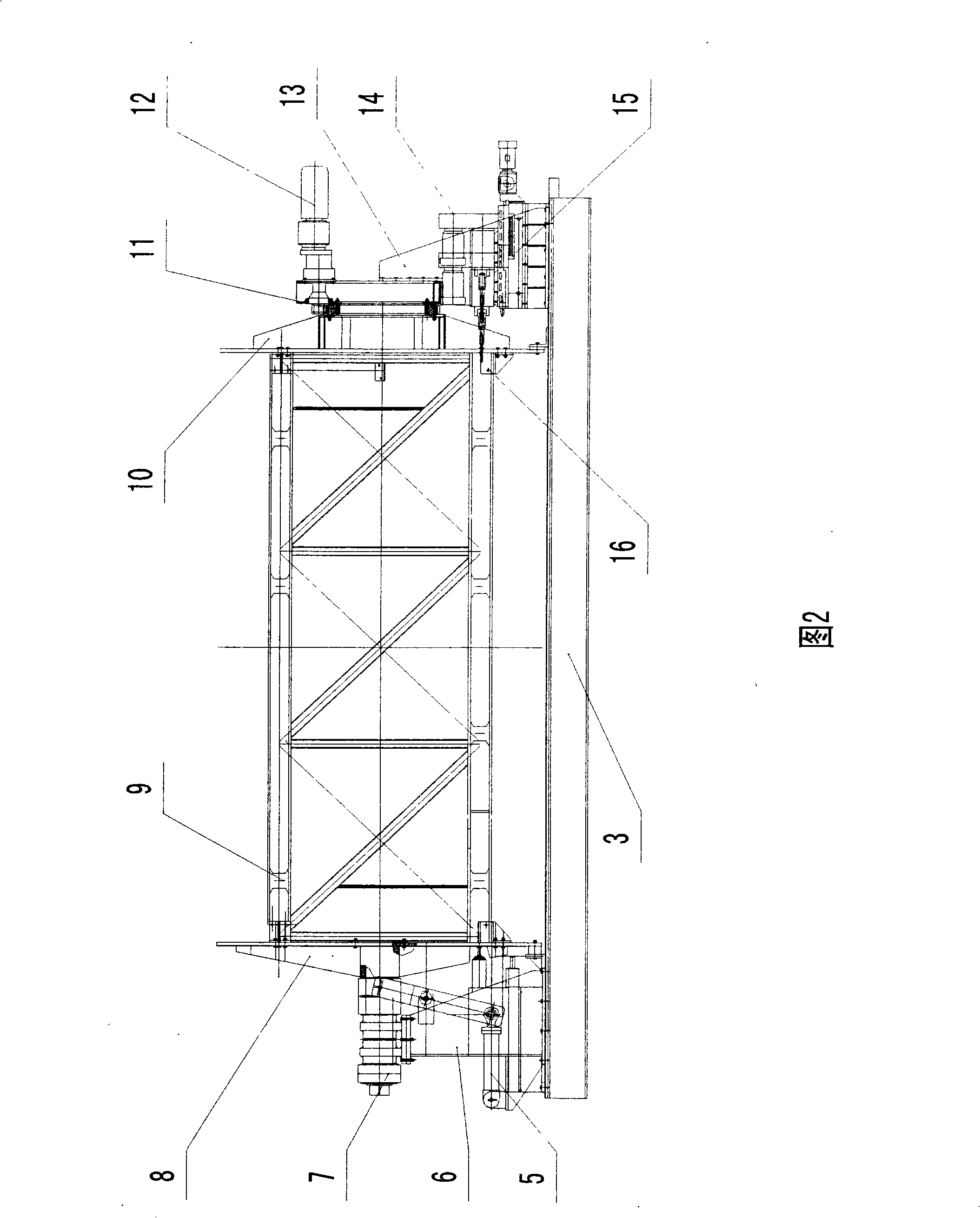

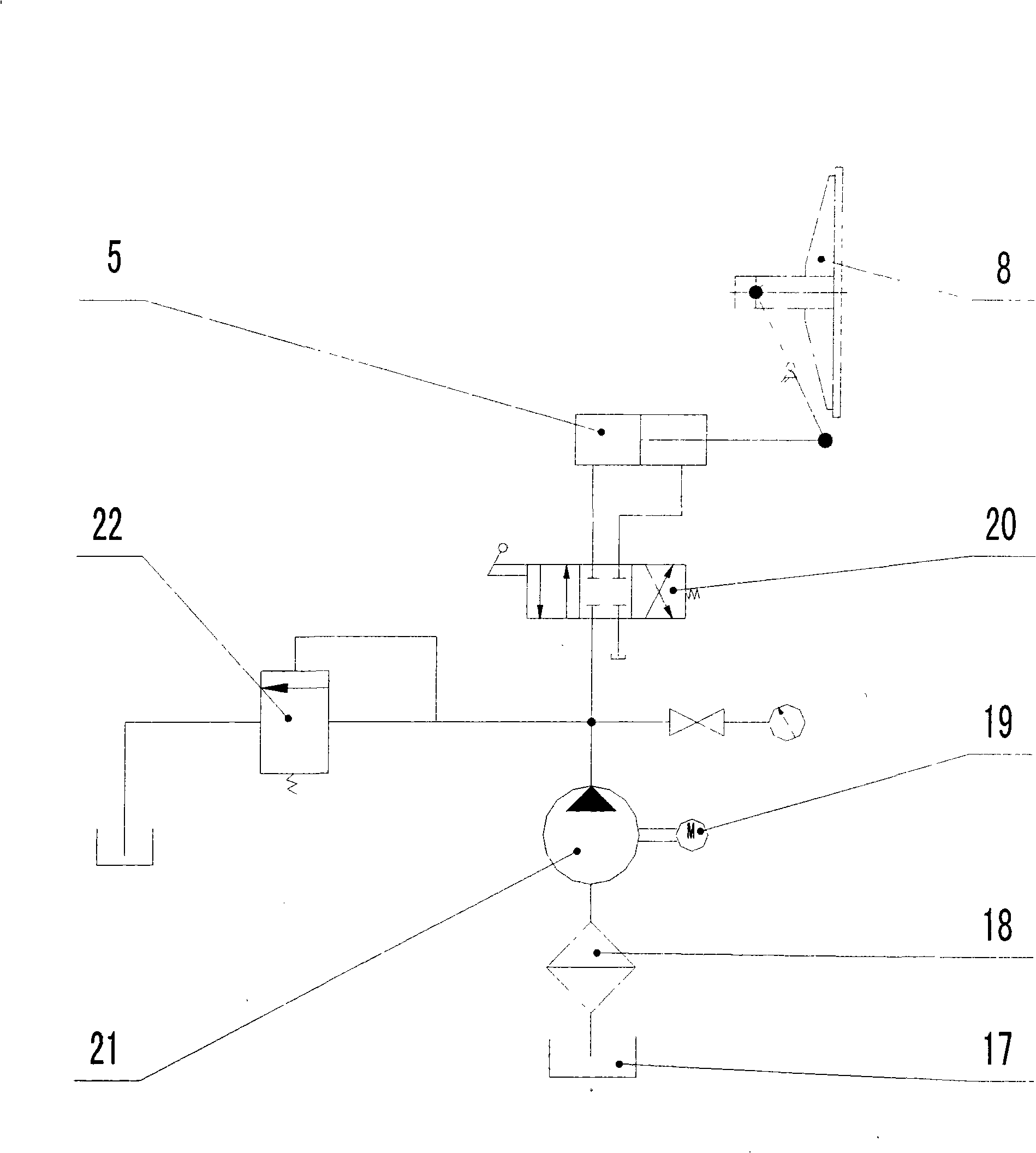

[0010] The fixed fixture has a fixed curved plate 4 on one end of the base 3, and a movable curved plate 2 on the other end. Move, clamp or release the workpiece. The bent plates at both ends of the fixed tooling can only clamp or loosen the workpiece, but cannot turn the workpiece over, let alone perform other processing operations such as drilling. In the present invention, a left rotating disc 8 and a right rotating disc 10 are arranged at both ends of the base 3, the outer central optical axis of the left rotating disc 8 passes through the shaft hole of the bearing seat 7, and can slide axially relative to the bearing seat 7, and the bearing seat 7 It is fixedly connected with the left support frame 6, and the left support frame 6 is fixed on the left end of the base 3; a hydraulic cylinder 5 is connected to the outside of the left rotary disc, and the hydraulic cylinder 5 can drive the left rotary disc 8 to move forward and backward through the connecting rod, and the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com