Gas metal arc welding process of medium-manganese wear-resistant steel and Q345B low-alloy steel

A Q345B, molten electrode gas technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., to save construction costs, reduce welding difficulty, and improve welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

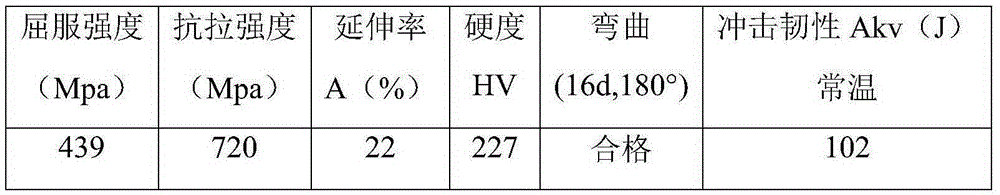

[0022] Embodiments The base metal is BTW1 medium manganese wear-resistant steel and Q345B low-alloy steel as examples, and the welding material is φ1.2mm welding wire, and its chemical composition and weight percentage are: C: 0.05-0.12%, Mn: 6.00-8.00% , P≤0.02%, S≤0.02%, Si: 0.70-1.00%, Cr: 17.00-19.00%, Mo≤0.10%, V≤0.10%, and the rest are iron and unavoidable impurities. The mechanical properties of BTW1 base metal are shown in Table 1.

[0023] Table 1 Mechanical properties of BTW1 medium manganese wear-resistant steel

[0024]

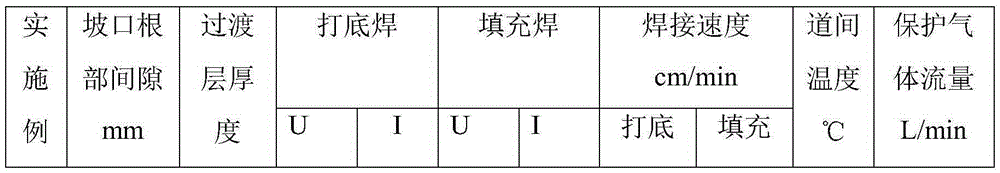

[0025] 1. The welding process parameters of BTW1 medium manganese wear-resistant steel and Q345B low alloy steel are as follows:

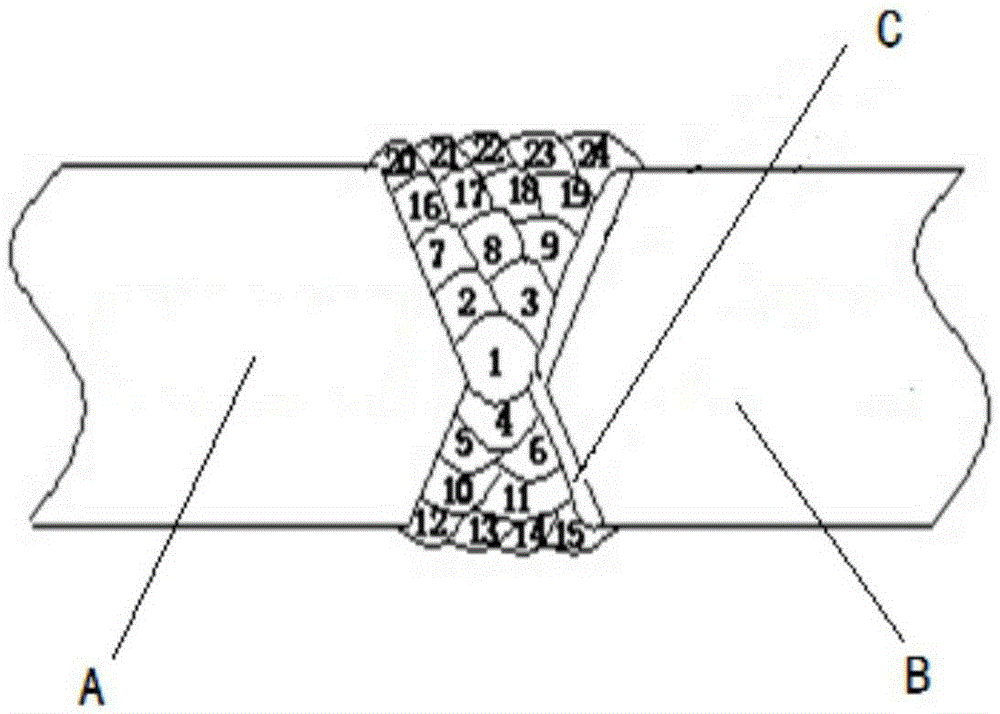

[0026] Double V-shaped grooves are made at the welded joints of BTW1 medium manganese wear-resistant steel and Q345B low-alloy steel base material, the opening angle is 60°, the groove depth is 18mm, and the gap at the root of the groove is 2-4mm after assembly; the selected protection The gas is Ar+5%CO 2 Mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| weld impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com