Laminated lithium ion battery and production process thereof

A lithium-ion battery and production process technology, applied in secondary batteries, electrochemical generators, circuits, etc., can solve the problems of the negative electrode being unable to perform normal charge and discharge, prone to false welding and leakage welding, battery capacity loss, etc. To achieve the effect of saving equipment investment and processing costs, reducing the probability, and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

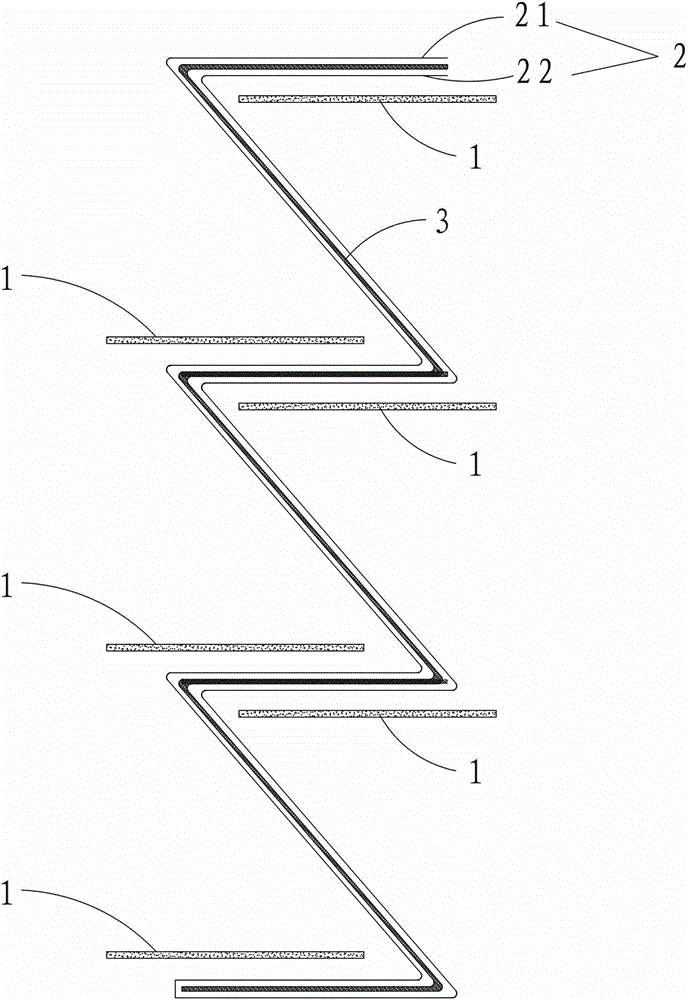

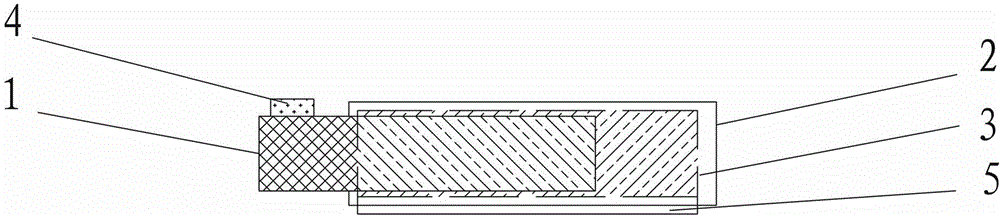

[0032] figure 1 This is a drawing diagram of the laminated structure of the lithium ion battery in this embodiment. The actual structure needs to figure 1 Fold it up. In this embodiment, a laminated lithium ion battery of the present invention includes a lithium ion battery core, see figure 1 The lithium ion battery core includes a positive electrode sheet 1, a separator 2 and a belt-type negative electrode sheet 3. The belt-type negative electrode sheet 3 is a continuous non-cut belt structure, and the belt-type negative electrode sheet 3 is wrapped by two layers of separator 2 ( That is, the upper surface and the lower surface of the belt-type negative electrode sheet are provided with separators) to form a coating body, and the two layers of separators are marked from top to bottom as the first separator 21 and the second separator 22; the coating is continuously folded to form a zigzag shape, The positive electrode sheet 1 is arranged at each bend of the zigzag cladding body...

Embodiment 2

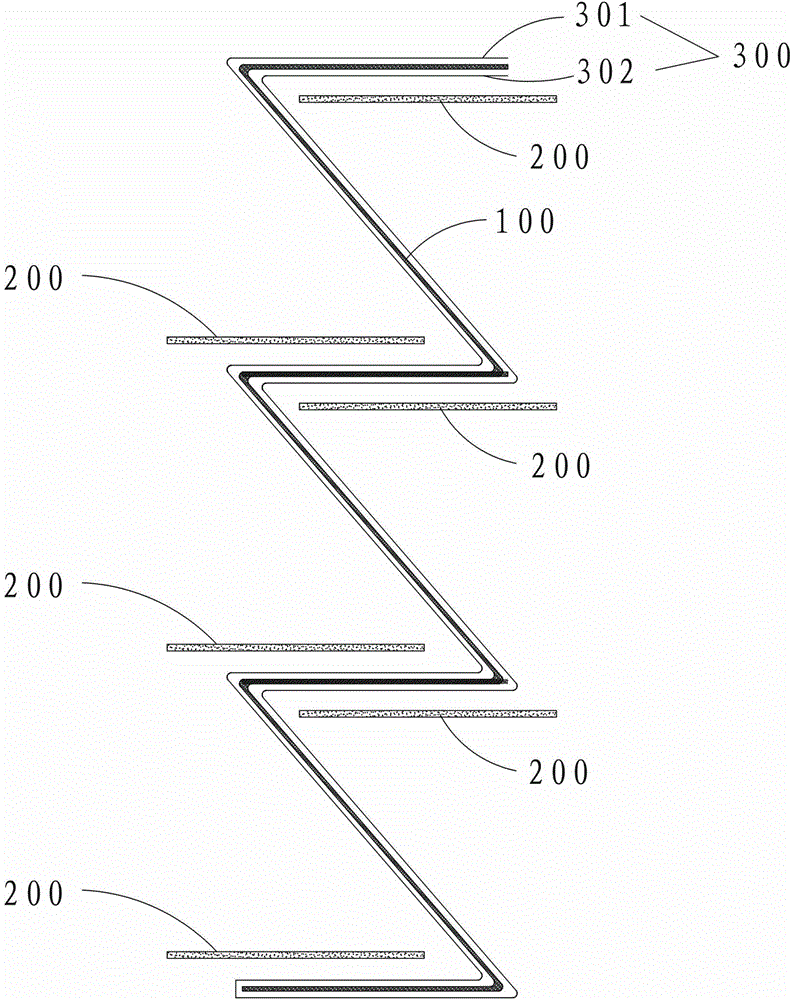

[0042] A laminated lithium ion battery, including a lithium ion battery core, see image 3 The lithium-ion battery core includes a belt-type positive electrode sheet 100, a negative electrode sheet 200, and a separator 300. The belt-type positive electrode sheet 100 is a continuous non-cut belt structure. The belt-type positive electrode sheet 100 is wrapped by a two-layer separator 300 (that is, The upper surface and the lower surface of the belt-type positive electrode sheet 100 are provided with separators 300) to form a coating. The two layers of separators 300 from top to bottom are marked as the first separator 301 and the second separator 302; the coating is continuously folded to form a zigzag , The negative electrode sheet 200 is arranged at each bend of the zigzag coating body, that is, in the vertical direction: the first separator 301, the belt-type positive electrode sheet 100, the second separator 302, the negative electrode sheet 200, the second separator 302, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com