Ladle pouring vehicle facilitating cleaning of residues in ladle

A ladle and residue technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of molten iron splashing in the ladle, failure to clean the bottom, and damage to the ladle, so as to reduce the vibration frequency and solve the problem of iron Liquid splashing, beneficial effect for efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

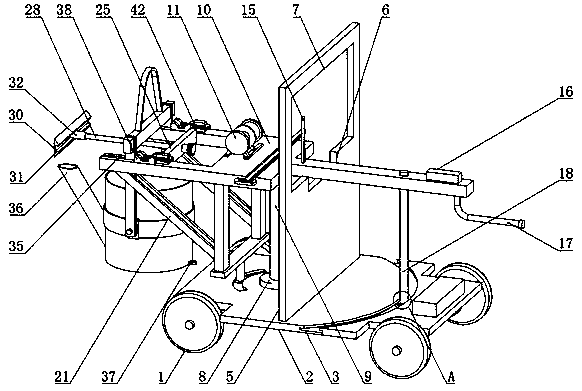

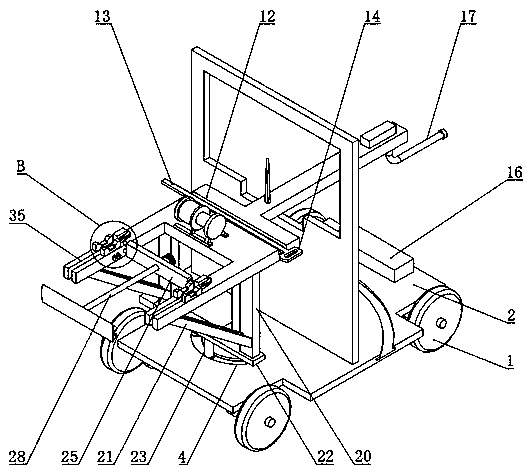

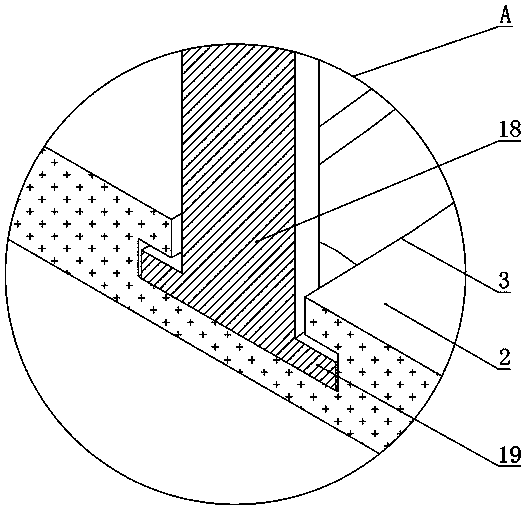

[0030] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a ladle watering vehicle for easy cleaning of residues in the ladle, including a watering vehicle body 1, a mounting base plate 2, a first limiting groove 3, a second limiting groove 4, a protective Plate 5, movable notch 6, observation glass plate 7, bearing mount 8, fixed shaft 9, mounting frame 10, hoist 11, storage slot 12, rack 13, handle 14, calibration cylinder 15, counterweight 16, Push rod 17, first support rod 18, limit projection 19, first support column 20, second support column 21, fixed plate 22, second support rod 23, installation shaft 24, installation plate 25, cylindrical projection 26 , block 27, cleaning rod 28, connecting thread 29, scraper 30, waste slag storage tank 31, first threaded sleeve 32, second threaded sleeve 33, first gear 34, card slot 35, ladle 36, traction Ring 37, damping block 38, drying chamber 39, damping gasket 40, damping spring 41, mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com