Polyvinyl chloride membrane for ginseng

A polyvinyl chloride and polyvinyl chloride resin technology, applied in the direction of plant protection cover, etc., can solve the problems of being unsuitable for large-scale popularization and application, uneven transmission of incident light, short service life of ordinary shed film, etc. The effect of large-scale promotion and application, avoiding high temperature burns, and facilitating field management and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Table 1

[0029] Raw material composition

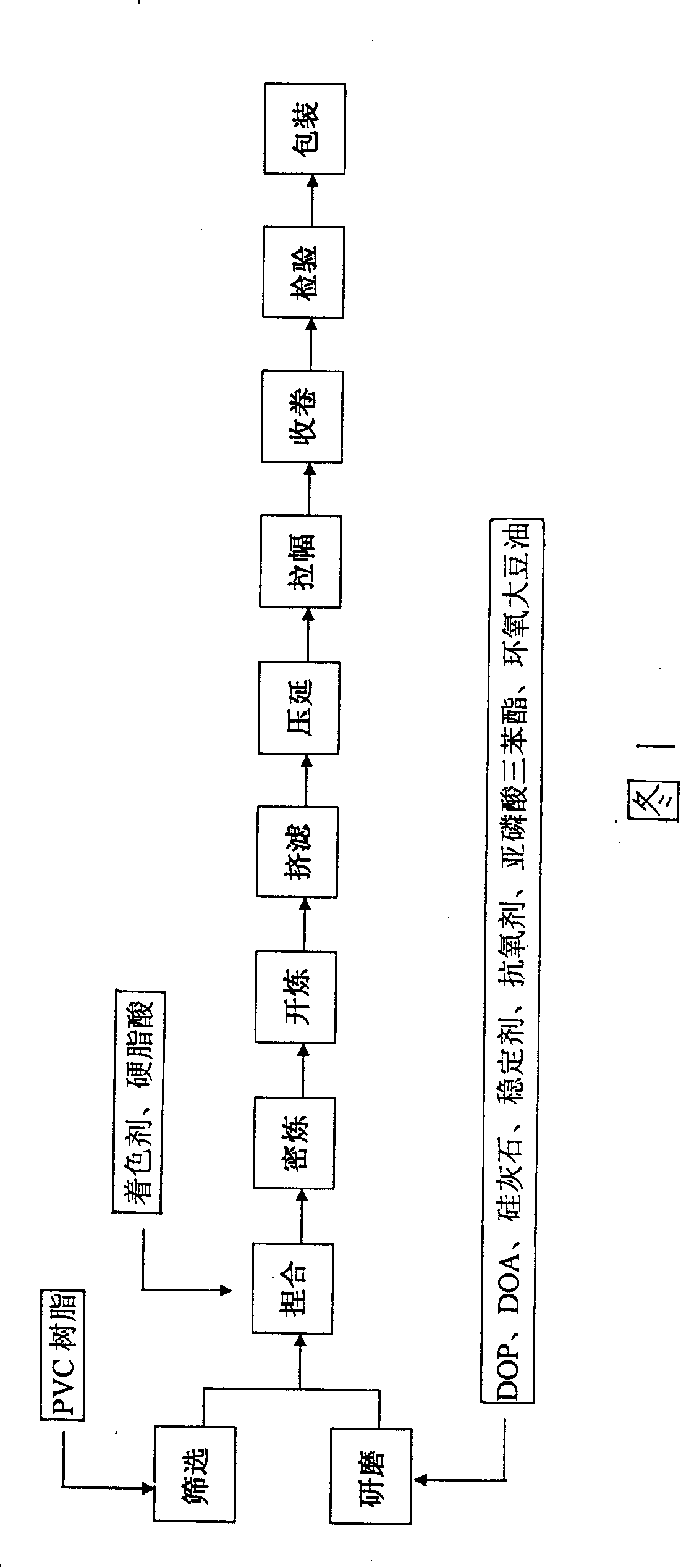

[0030] The preparation of the product of the present invention uses the formula raw materials in above-mentioned table 1, at first SG-2 type PVC resin is screened through the vibrating sieve of screening process, and the vibrating screen is 60 orders; In grinding process, DOP, DOA, epoxy soybean oil, Triazine-5, 1076, barium stearate, cadmium stearate, zinc stearate, triphenyl phosphite, and wollastonite are stirred by a mixer, and then ground and mixed by a three-roll mill, and the grinding slurry is passed through a 100-mesh Copper mesh filter, mixed pulp; put PVC resin, mixed pulp, stearic acid, phthalocyanine blue BGS into the high-speed kneader of the kneading process in the order of PVC resin, mixed pulp, and other additives according to the formula ratio and knead at a high speed , the kneading time is 5 minutes, and the vapor pressure is 0.5MPa; the kneaded material is banburyed (vapor pressure is ...

example 1

[0031] In Example 1, the proportion of 3 parts of silica fume (2000 mesh) was selected, and the light transmittance of the produced polyvinyl chloride ginseng film was 55%, and the haze value was 48%.

Embodiment 2

[0032] Example 2: Table 2

[0033] Raw material composition

[0034] The preparation of the product of the present invention uses the formula raw materials in the above-mentioned table 2, first the SG-2 type PVC resin is screened through a screening process vibrating screen, and the vibrating screen is 60 orders; in the grinding process, DOP, DOA, epoxy soybean oil, Triazine-5, 1076, triphenyl phosphite, barium stearate, cadmium stearate, zinc stearate, and wollastonite are stirred by a mixer, and then ground and mixed by a three-roll mill, and the grinding slurry is passed through a 100-mesh Copper mesh filter, mixed pulp; put PVC resin, mixed pulp, stearic acid, medium chrome yellow into the high-speed kneader of the kneading process in the order of PVC resin, mixed pulp, and other additives according to the formula ratio, and knead at a high speed. The kneading time is 7 minutes, and the vapor pressure is 0.4MPa; the kneaded materials are banburyed (vapor pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com