Device and method for improving battery pole piece slit curling

A battery pole piece and incision technology, which is applied to the device for coating liquid on the surface, electrode manufacturing, spraying device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

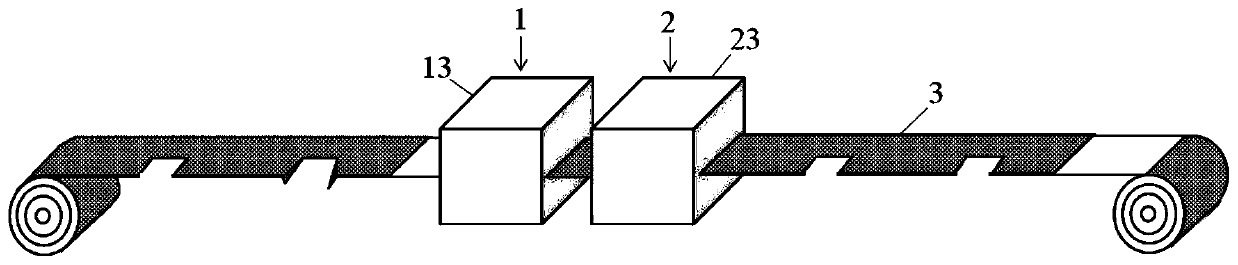

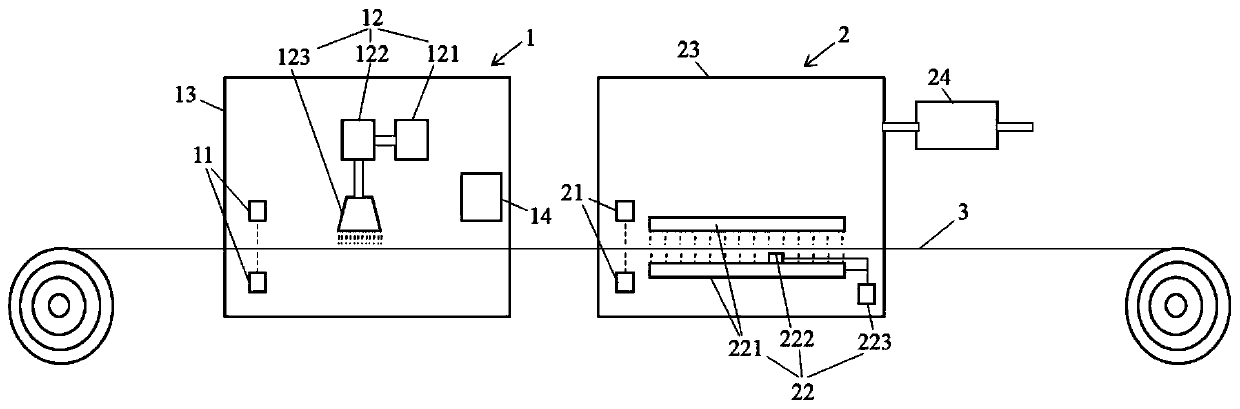

[0035] Such as Figure 1-2 As shown, a device for improving the crimping of battery pole piece incisions includes a coating module 1 and a drying module 2. The coating module 1 is used to identify single-sided pole pieces with special-shaped cuts, and to treat single-sided poles with special-shaped cuts. The sheet is sprayed, and the drying module 2 is used to identify the single-sided pole piece with special-shaped cut from the coating module 1, and to bake the single-sided pole piece with special-shaped cut. In actual work, the coating module 1 and the drying module 2 are arranged adjacently, the battery pole piece 3 flows through the coating module 1 and the drying module 2 in turn, and the coating module 1 sprays fog on the single-sided pole piece with special-shaped incision The solvents used include polar solvents (such as water, alcohols, etc.), non-polar solvents (such as acetone, NMP, etc.), mixed solvents (multiple polar or non-polar solvents are mixed in a certain pr...

Embodiment 2

[0046] Such as Figure 1-2 As shown, a method for improving the crimping of the battery pole piece in embodiment 1 or 2 or 3 includes the following steps:

[0047] S1. Connect the battery pole piece 3 to the coating module 1;

[0048] S2. The first sensor 11 recognizes a single-sided pole piece with a special-shaped cut in the battery pole piece 3, and transmits the signal to the spraying system 12;

[0049] S3. The spraying system 12 coats single-sided pole pieces with special-shaped cuts;

[0050] S4. Immediately after the battery pole piece 3 is connected to the drying module 2;

[0051] S5. The second sensor 21 recognizes a single-sided pole piece with a special-shaped cut in the battery pole piece 3, and transmits the signal to the drying system 22;

[0052] S6. The drying system 22 blows hot air to dry the single-sided pole pieces with special-shaped incisions;

[0053] S7. The third sensor 222 monitors the surface temperature of the single-sided pole piece with the special-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com