3D printing polylactic resin material and preparation method thereof

A polylactic acid resin, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of soft products, unfavorable families, insufficient support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

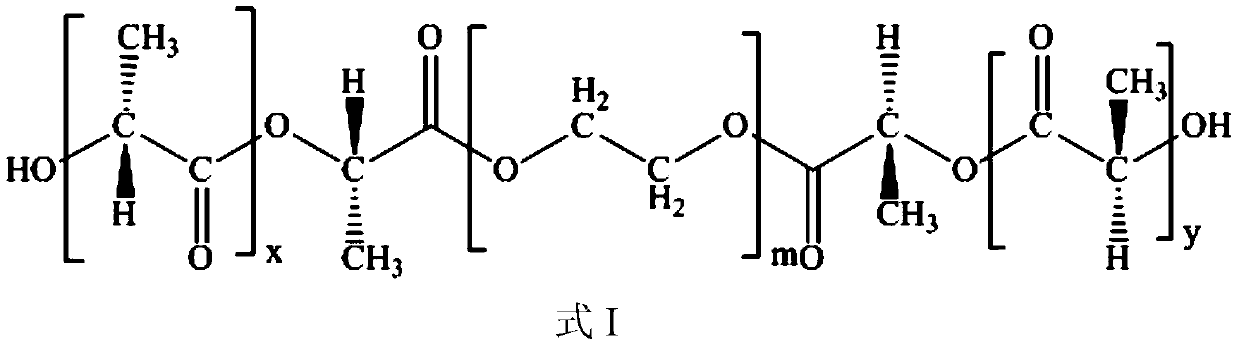

[0071] The preparation method of polylactic acid-b-polyethylene glycol block copolymer of the present invention can comprise the following steps:

[0072] (1) Lactide, polyethylene glycol or polyethylene glycol methyl ether, catalyst are mixed in the first solvent, in protective gas such as N 2 heating and stirring under the protection;

[0073] (2) The product of step (1) is extracted and dried.

[0074] In one embodiment, the lactide in step (1) can use L-lactide, D-lactide or a combination thereof.

[0075] In another embodiment, the catalyst in step (1) is an organotin catalyst, preferably organotin octoate, dibutyltin dilaurate, stannous octoate, dibutyltin di(dodecylsulfide), chloride Stannous, alkyl tin dithiolate, or combinations thereof.

[0076] In yet another embodiment, the number average molecular weight of polyethylene glycol in step (1) is about 0.2-100,000, preferably about 0.2-30,000, such as about 2,000, about 5,000, about 8,000, about 10,000 , about 13,0...

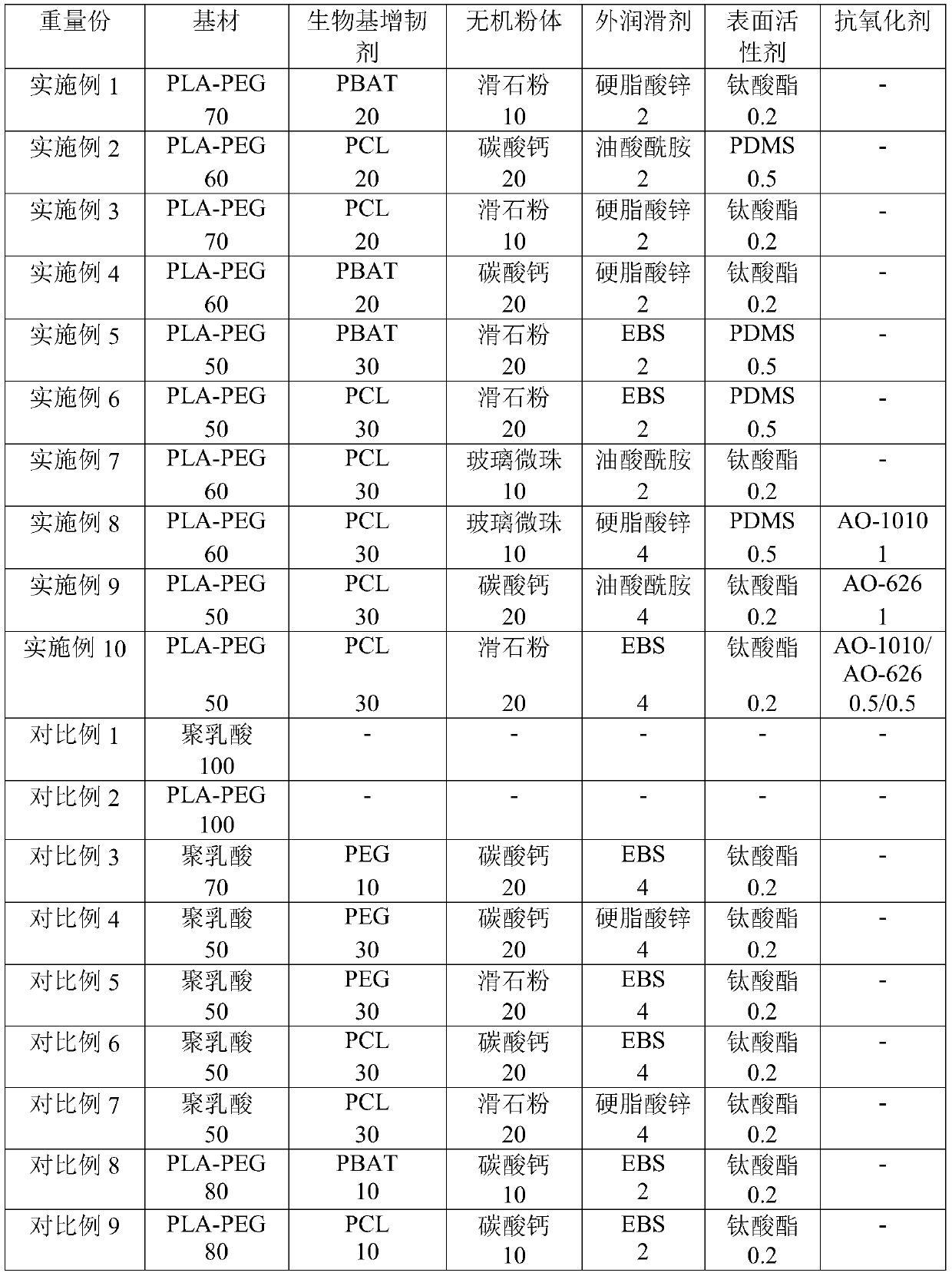

Embodiment

[0147] The solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com