Automatic control device of material cold and hot circulation performance and operating method thereof

An automatic control device, a technology of cooling and heating cycles, applied in the investigation phase/state change and other directions, can solve the problem of many heating-cooling cycles, long experimental periods (as few as a few months, as long as one or two years, and easy for the experimenter). Fatigue and other problems, to achieve the effect of speeding up heating and cooling rates, avoiding high temperature burns, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

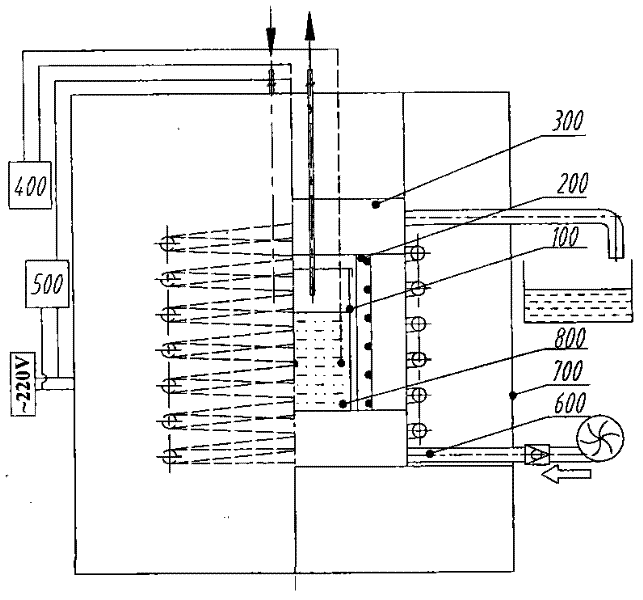

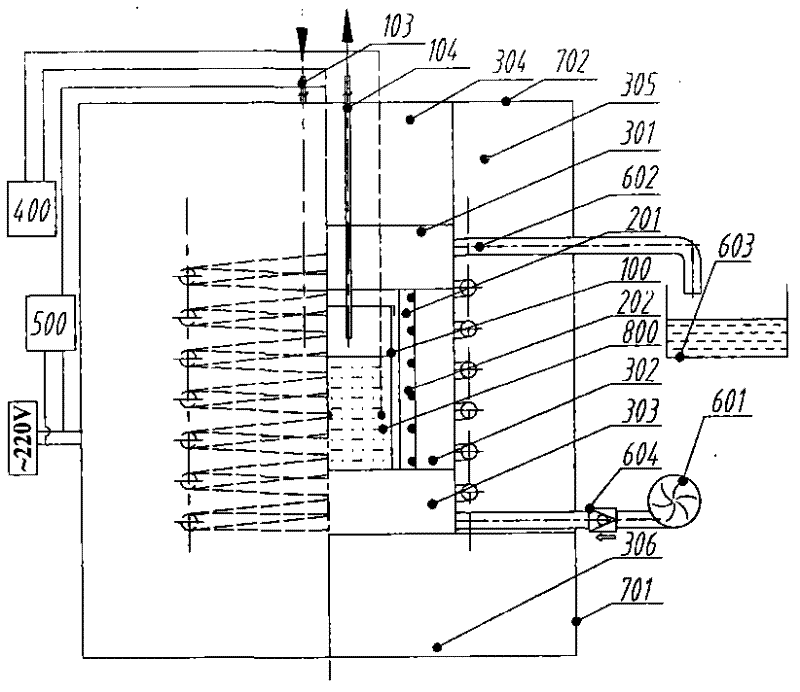

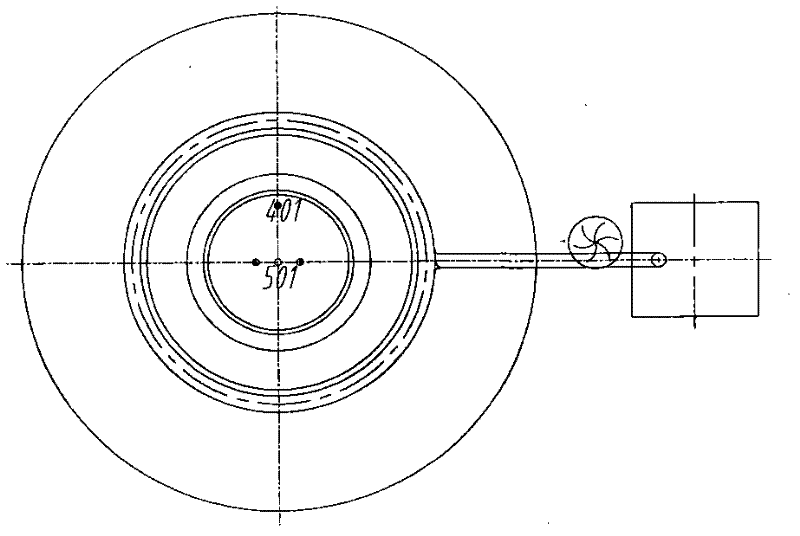

[0076] Below in conjunction with the embodiment of specific material (analytical pure sodium chloride), including details such as container material selection, the operation process of this experimental device is described in detail:

[0077] Taking industrial NaCl as an example, using the device of the invention, a temperature range of 300-900°C ± 10°C, 1000 melting-solidification cycle experiments were carried out, and the melting point / freezing point value was measured at the same time.

[0078] The melting point of chemically pure NaCl is 800°C, and it is expected that the maximum temperature may reach 950°C. Therefore, using a K-type armored thermocouple, the measurable temperature range is 0 to 1300°C. The sample chamber 100 is made of 310s stainless steel and processed by TIG welding. The total time of this cycle experiment is short, and the corrosion of the sample chamber by molten NaCl is not obvious, so the influence of this corrosion on the experiment and measuremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com