Brake for hydrostatic drive

A brake and hydrostatic technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of complex processing, assembly and maintenance of brakes, easy wear and tear of pistons, etc., and achieve convenient processing, assembly and maintenance, and lubrication Good effect, reducing piston sticking and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

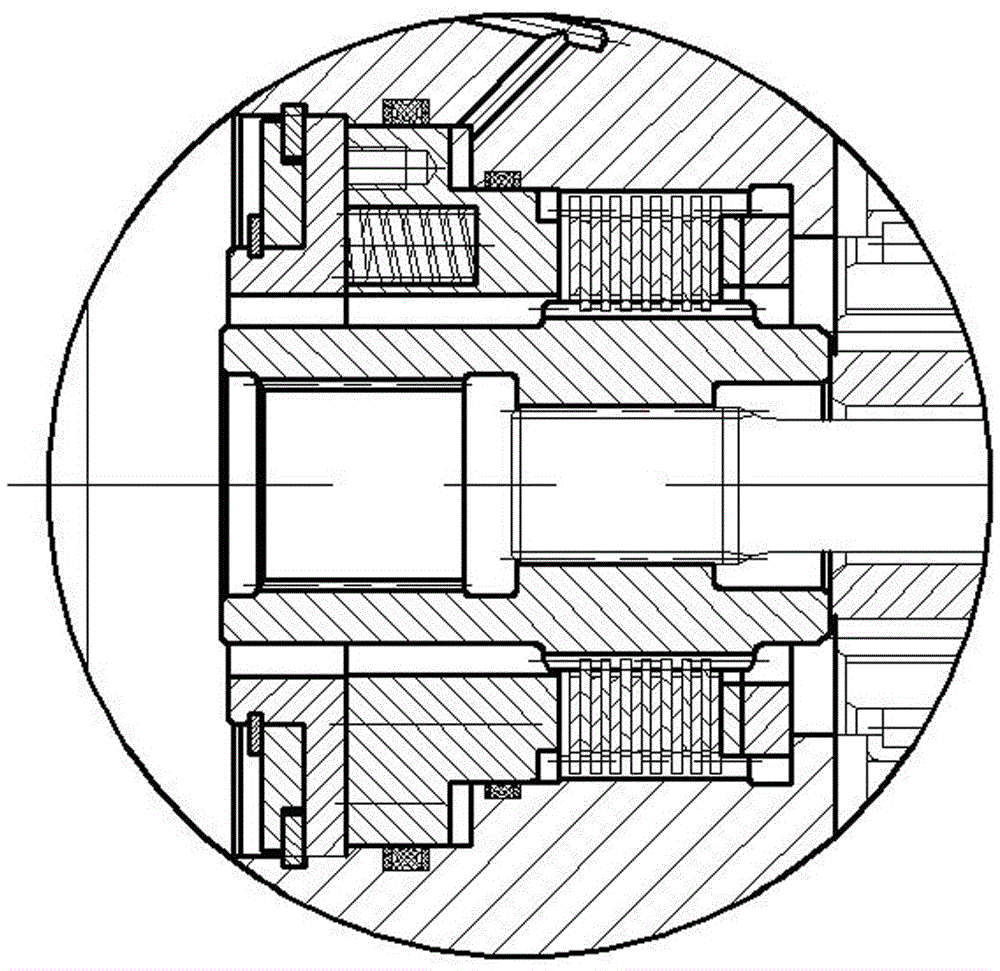

[0027] figure 1 It is a schematic diagram of an existing Rexroth travel deceleration mechanism. As mentioned in the above background technology, this kind of brake has the problems of complicated processing, assembly and maintenance, easy wear of the piston and high cost.

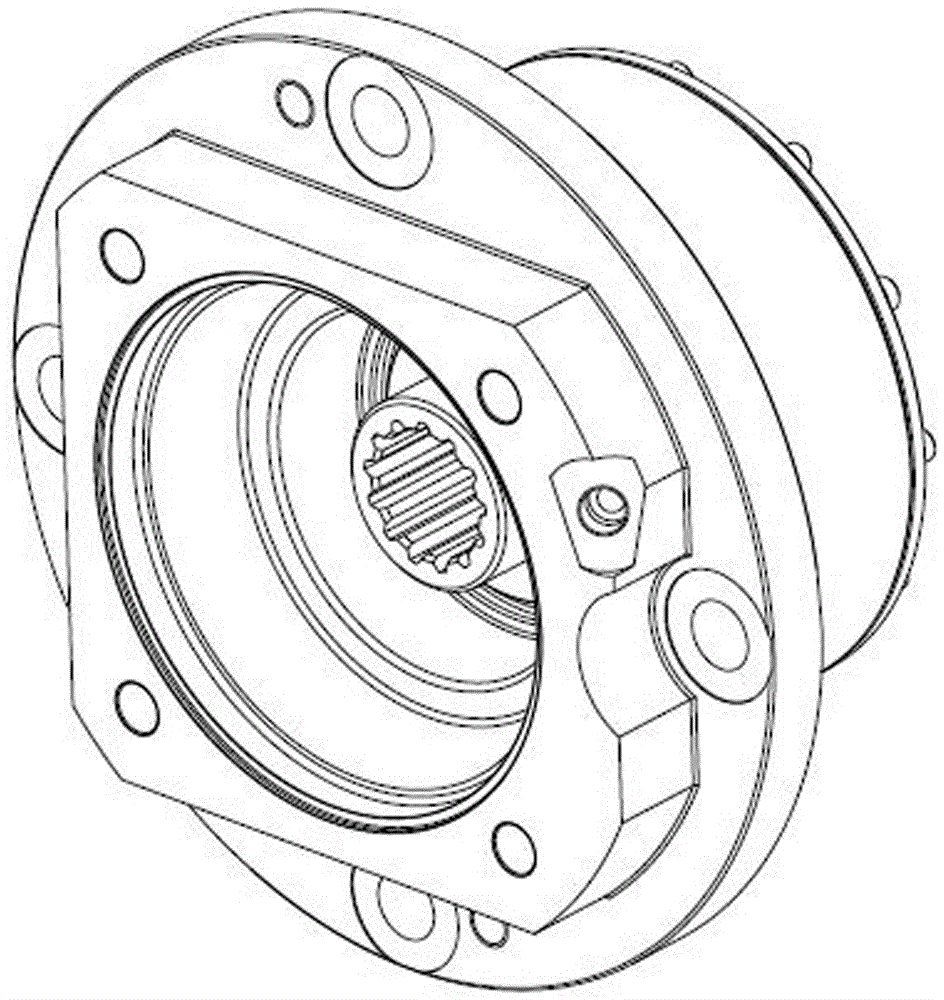

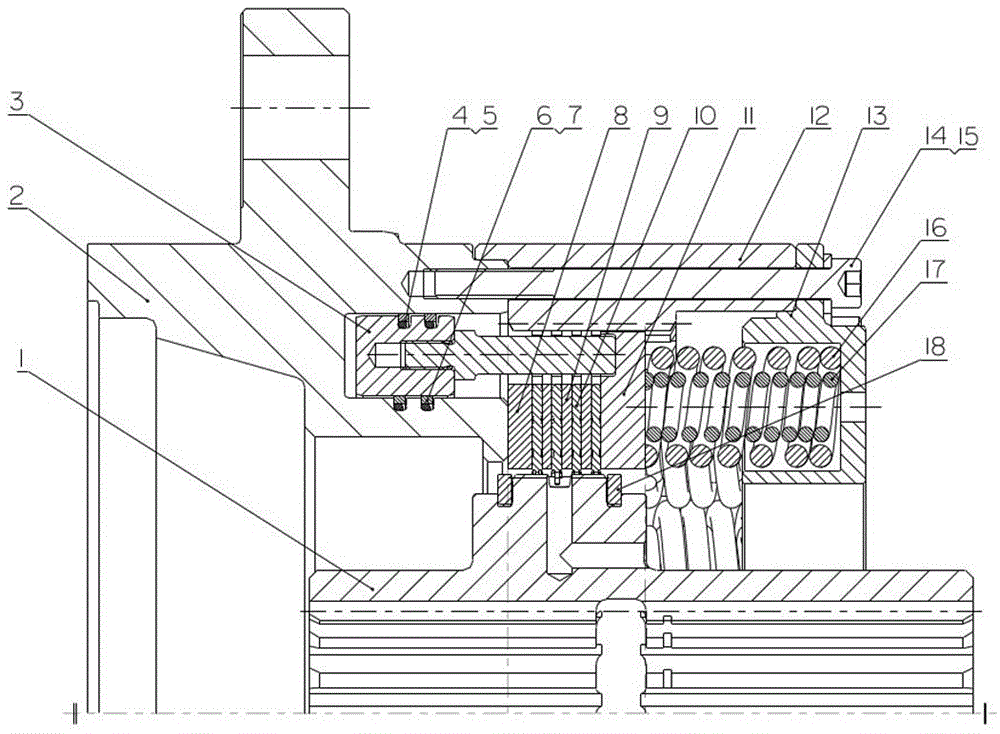

[0028] figure 2 with image 3 The brake used for hydrostatic transmission includes a cylinder body 2, a piston assembly 3 and a power take-off shaft 1 installed in the cylinder body 2; as Figure 4 As shown, the power take-off shaft 1 includes a left end internal spline 1-1 for connecting the input part of the hydraulic motor, a right end internal spline 1-2 for connecting the output part of the reduction gear, and a brake for connecting the friction pair. Part of the top splines 1-3; the two sides of the top splines 1-3 are fitted with limit retaining rings 18, and the power take-off shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com