Waterborne epoxy curing agent-based nylon wheel and preparation method thereof

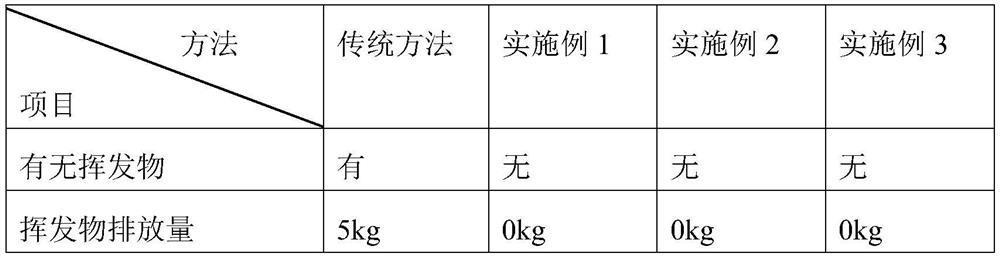

A water-based epoxy and curing agent technology, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as non-compliance with environmental protection policy requirements, organic volatiles easily exceeding the standard, pollution, etc., to improve organic volatile The effect of pollutant discharge pollution problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail in conjunction with specific embodiments.

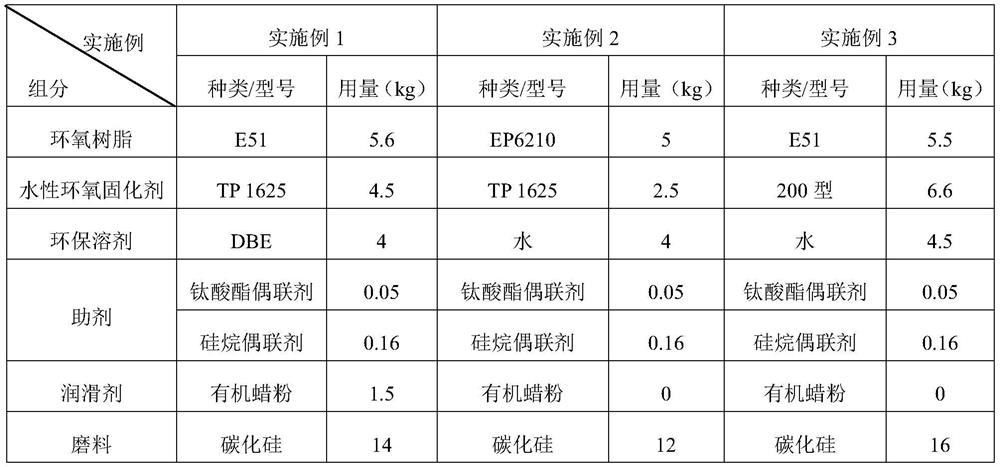

[0019] The nylon wheel based on water-based epoxy curing agent of the present invention comprises nylon fiber non-woven fabric and the wear-resistant mortar coated on the nylon fiber non-woven fabric, and the wear-resistant glue comprises the following components by weight: 100 parts of epoxy resin, 50-250 parts of water-based epoxy curing agent, 150-300 parts of abrasive, 40-100 parts of environmentally friendly solvent, 2-10 parts of auxiliary agent, and 0-50 parts of lubricant.

[0020] When preparing nylon wheels, measure the proportion and content of the required components, heat the epoxy resin and water-based epoxy curing agent to 30°C-40°C, and add epoxy resin, Water-based epoxy curing agent, environmentally friendly solvents, additives, abrasives, lubricants, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com