A solvents non -woven non -woven polishing wheel and its manufacturing method

A non-woven fabric and polishing wheel technology, which is used in the manufacture of tools, textiles and papermaking, grinding/polishing equipment, etc., can solve the problems of not achieving green production, excessive organic volatiles, etc., and avoid high temperature burns in workpiece production. , Product structure enhancement, the effect of reducing the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

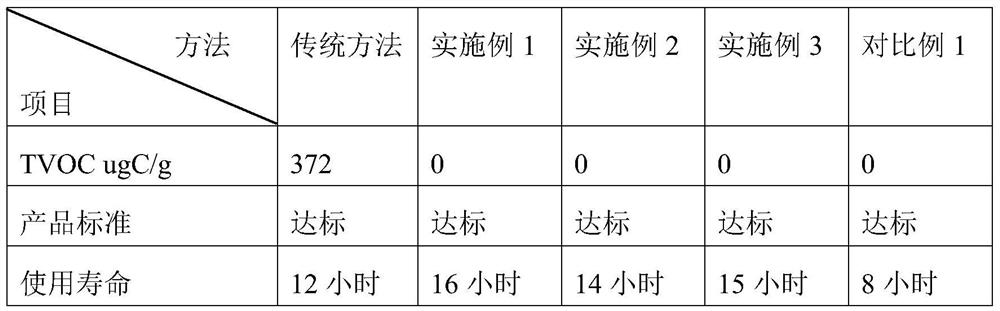

[0024] Aiming at the shortcomings of the non-woven polishing wheels used in the prior art, the present invention proposes a solvent-free non-woven polishing wheel and a preparation method thereof, which solve the problem of the existing epoxy system non-woven polishing wheels or polyurethane prepolymers. The non-woven polishing wheel of the method needs to be diluted with an organic solvent, which causes the problem of organic solvent volatilization in the preparation process.

[0025] The solvent-free type non-woven polishing wheel of the present invention comprises 80-120 parts of polyisocyanate, 50-150 parts of oligomer polyol, 5-25 parts of chain extender, 4-15 parts of cross-linking agent, 150-300 parts of abrasive, 5-20 parts of toner, and 10-50 parts of lubricant; in order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, three specific embodiments will be used for detailed description below.

[0026] Ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com