Novel pumping pressure four-stroke four-cylinder layering vortex combustion energy-saving gasoline engine

A four-stroke, gasoline engine technology, applied to combustion engines, liquid fuel feeders, internal combustion piston engines, etc., can solve the problem of insufficient fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

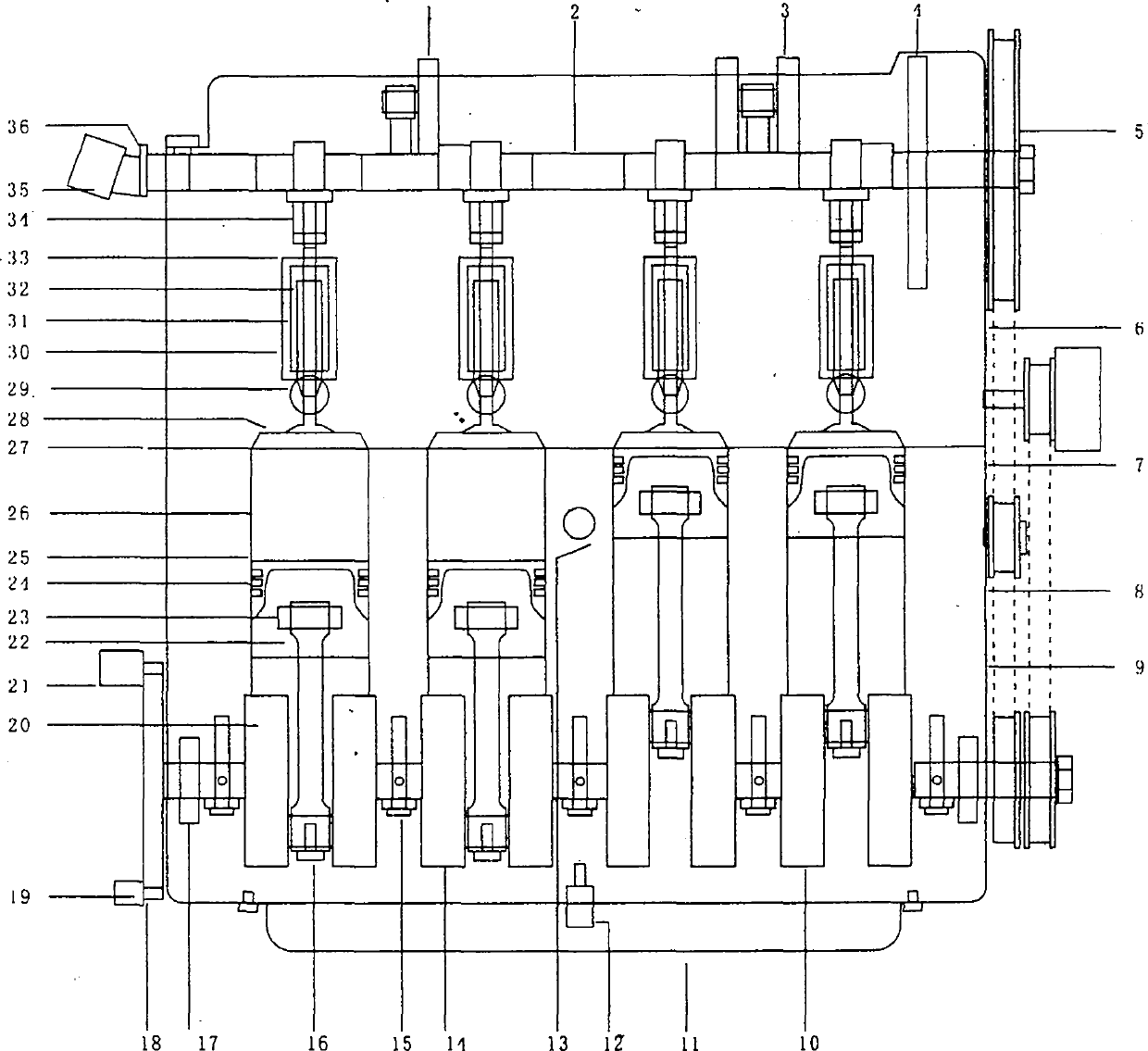

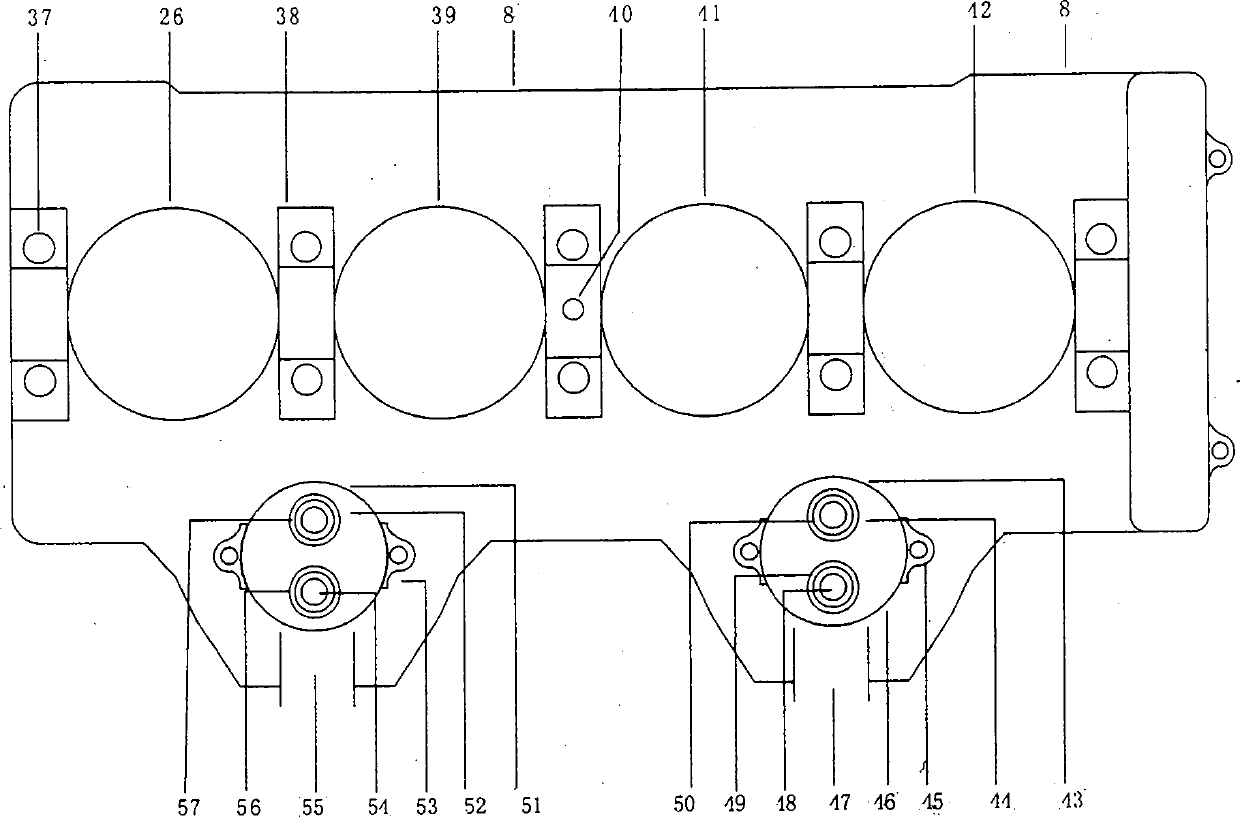

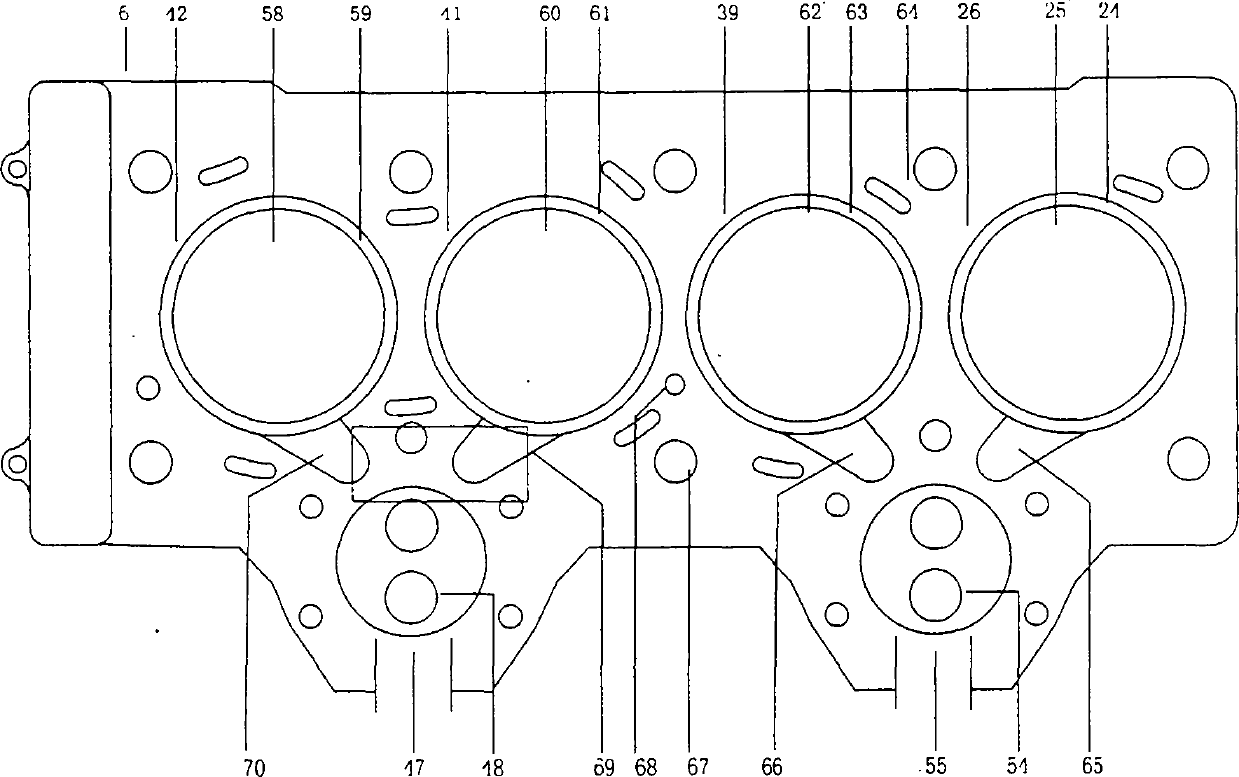

[0029] The embodiment of the patent of the present invention is in figure 1 Middle: The four chain rods (22) and the four chain rod bottom tile covers (16) are respectively connected with the four crank pins on the crankshaft (20), and each chain rod (22) is fixed with two bolts. Then take four sets of piston rings (24), (59), (61) (63) and put them into the ring positions of the four pistons (25) (58) (60) (62). )(58)(60)(62) are respectively connected with the piston pins on the four chain rods (22), each with a piston pin (23) connected with each chain rod (22), and each with two piston pins (22). A circular circlip fixes each piston pin (23), and then installs the crankshaft (20) and the four pistons (25) (58) (60) (62) into the crankcase (8) and the four cylinders (26) respectively. )(39)(41)(42), cover each crankshaft bottom tile cover(15) on the shaft position of the crankshaft(20), and fix each with two screws, and then install the oil pan cover(11) ) are fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com