An electronic water pump for an engine

An electronic water pump and engine technology, which is applied to engine components, engine cooling, machine/engine, etc., can solve the problems of increased engine power loss, decreased engine oil temperature, increased viscosity, etc., to improve fuel consumption and emission pollution, and reduce exhaust gas Emissions, energy-saving effects of exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

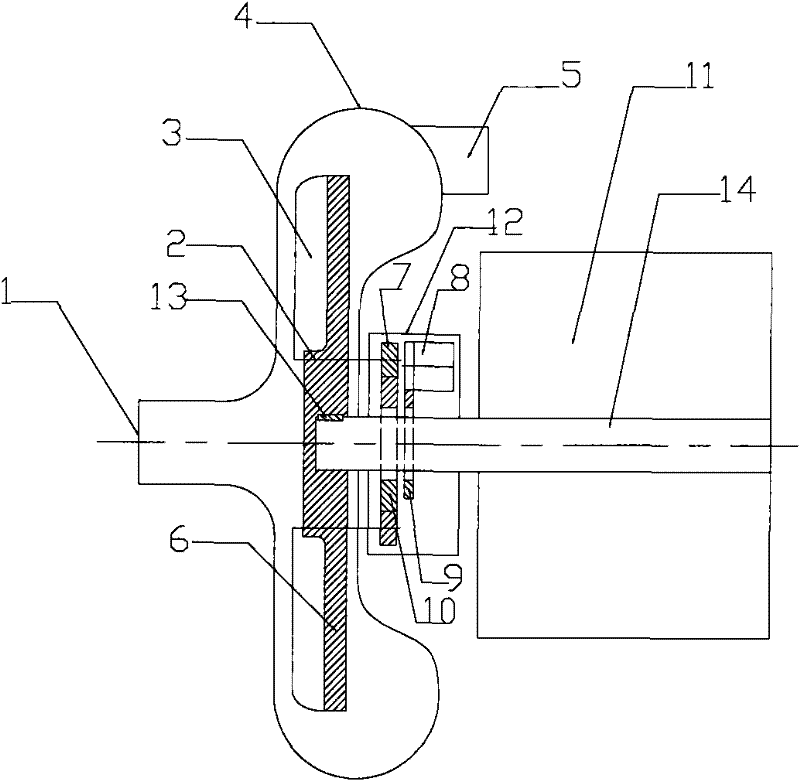

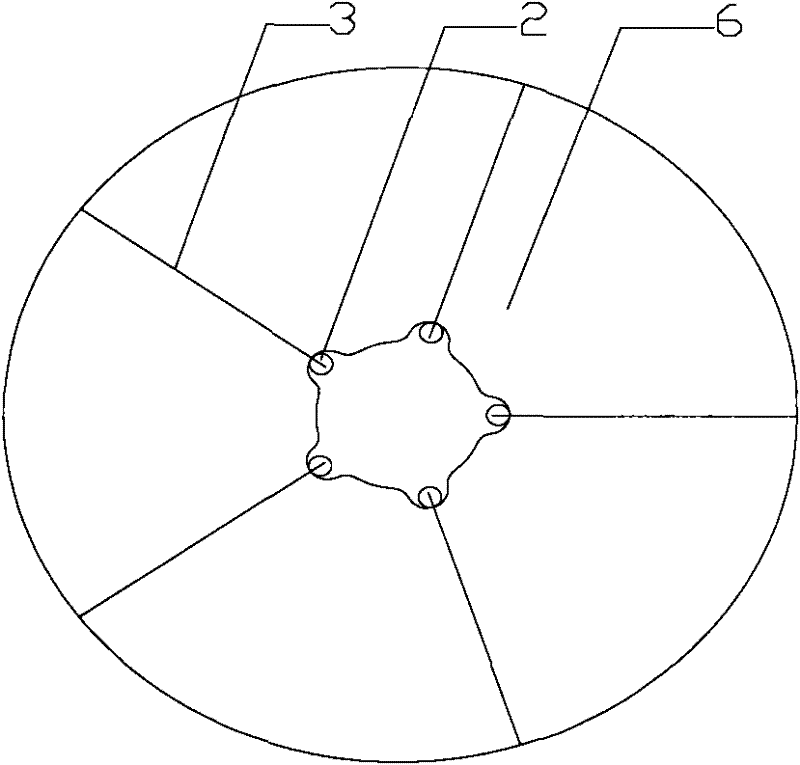

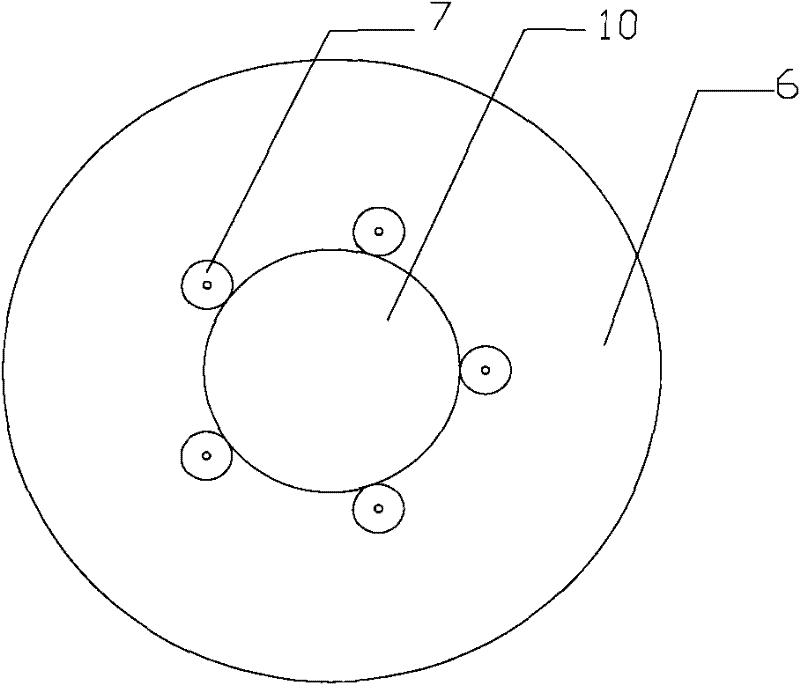

[0020] Depend on Figure 1-Figure 4 It can be seen from the combination that the electronic water pump of this kind of engine includes a water pump shaft 14, one end of the water pump shaft 14 is connected with the water pump motor 11, and the end of the other end is fixedly installed with the water pump wheel 6 through the key 13, and the water pump blade shaft 2 is installed on the water pump wheel 6. The water pump blade shaft 2 is independently controlled by the water pump blade motor 8, and the water pump blade shaft transmission gear 10 installed on the water pump shaft 14 near the end of the water pump housing 4 drives the water pump blade shaft 2 to rotate, and the water pump blade 3 is fixedly installed on the water pump blade shaft 2 , the outside of the water pump blade 3 is provided with a water pump housing 4, one end of the water pump housing 4 is sealed and installed on the water pump shaft 14, the other end is provided with a water pump inlet 1, and the water pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com