Welding clamping device

A clamping device and welding clamp technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient turning of trapezoidal workpieces, irregular placement of welding torches, and poor absorption of welding fumes, etc., so as to facilitate classification and Use, good welding fume adsorption effect, avoid high temperature burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

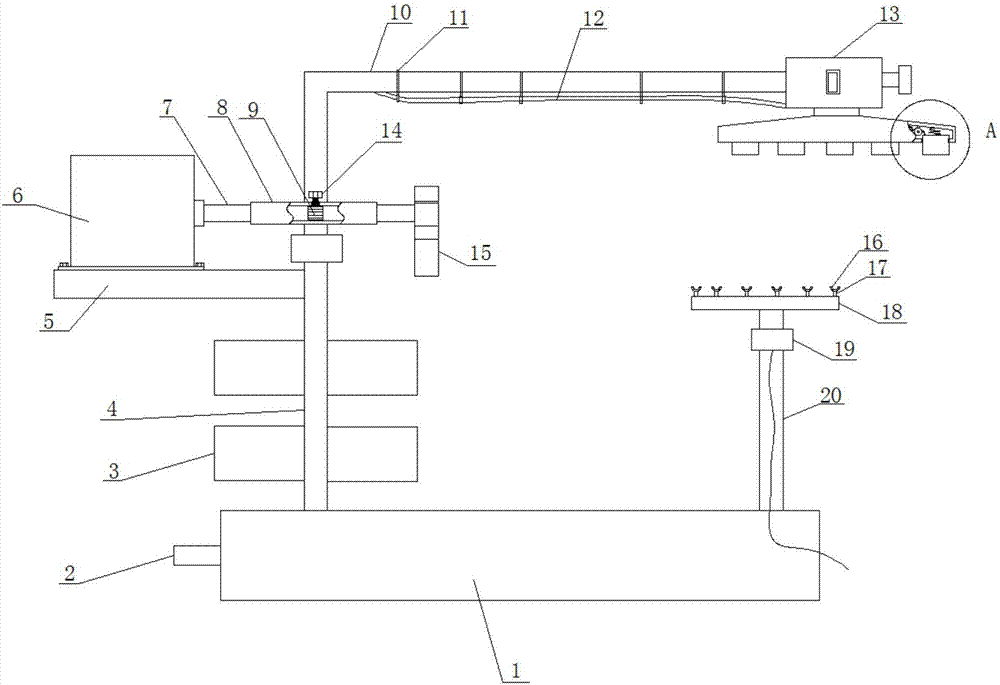

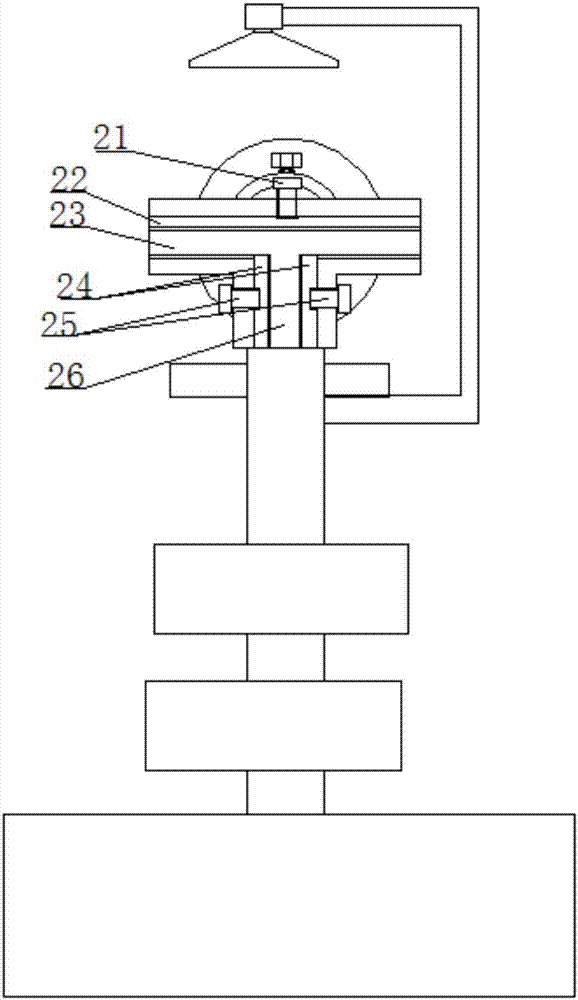

[0033] Such as Figure 1-Figure 4 As shown, a welding clamping device includes a base 1, and the two sides of the upper end of the base 1 are respectively provided with a clamping device and a welding torch fixing device;

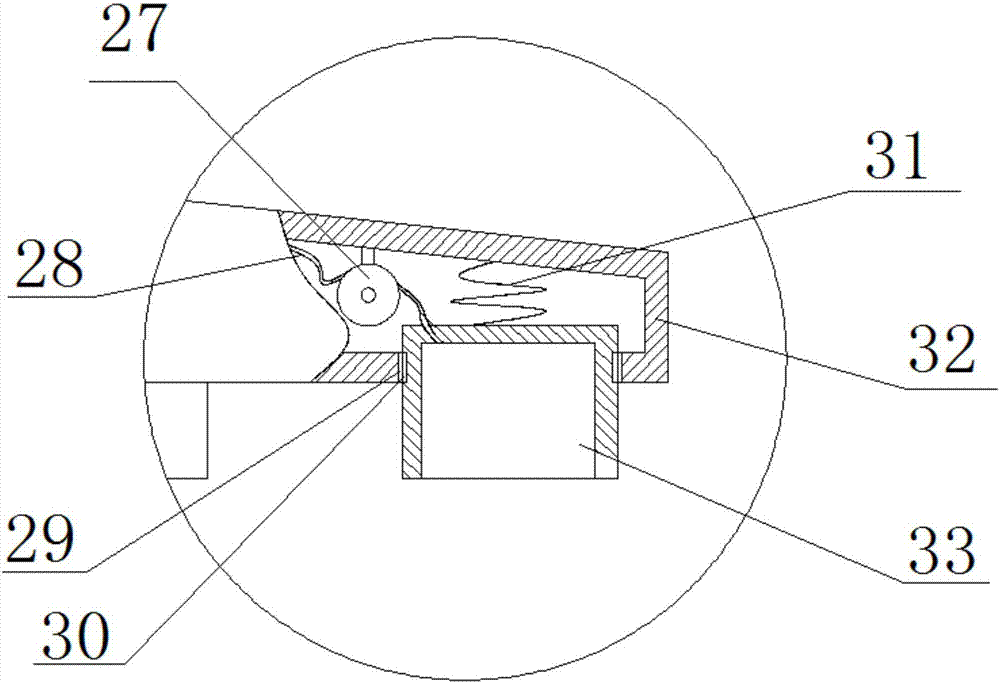

[0034] The clamping device includes a hollow vertical rod 4, the upper end of which is connected to a horizontal sleeve 8, the horizontal sleeve 8 is provided with a rotatable rotating shaft 7, and one end of the rotating shaft 7 is provided with a clamping body 15 , the end face of the clamping body 15 forms a trapezoidal groove, and the three notches of the trapezoidal groove are all open; the upper end of the hollow vertical rod 4 is also provided with a support plate 5, and the support plate 5 is provided with a transmission box 6 with a rotating motor , the output shaft of the transmission box 6 is connected with the other end of the rotating shaft 7;

[0035] Described welding torch fixing device comprises hollow support bar 20, and hollow support ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com