Method for preparing particulate reinforced metal-based composite material

A composite material and particle reinforcement technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problem of poor bonding between the hard phase and the metal matrix phase interface, and achieve the effects of uniform distribution of hard phase, high production efficiency, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

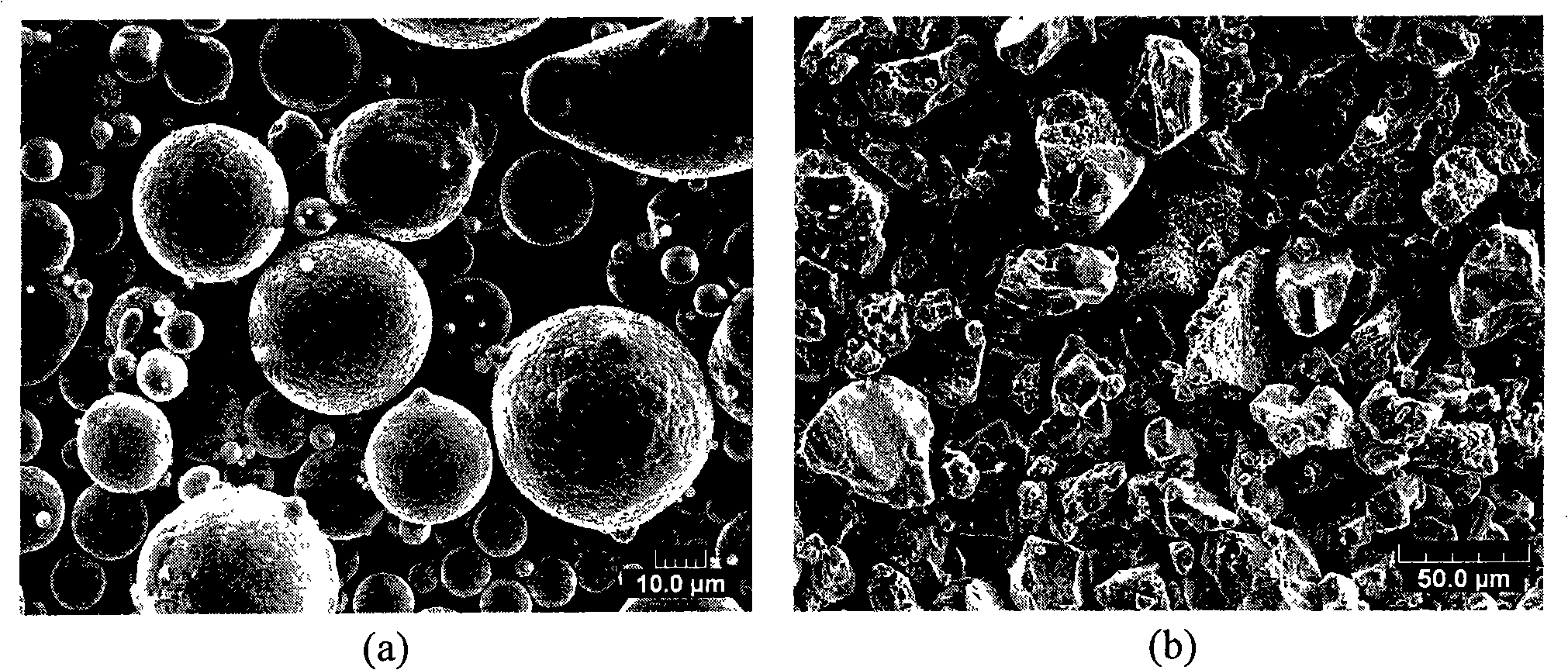

[0027] The metal matrix material is selected as Al alloy powder (Al5356), and the particle size of the powder is 5-63 μm; the TiN powder is selected as the hard phase particle, and the particle size is 11-45 μm; the morphology of the two original powders is as follows figure 1 As shown, Al5356 is basically spherical, and TiN is irregular polygonal.

[0028] The Al5356 powder and TiN powder were mixed according to a weight ratio of 50wt% (volume ratio of 32.7vol% TiN), put into a plastic bottle, and then mixed with a powder mixer for 30 minutes.

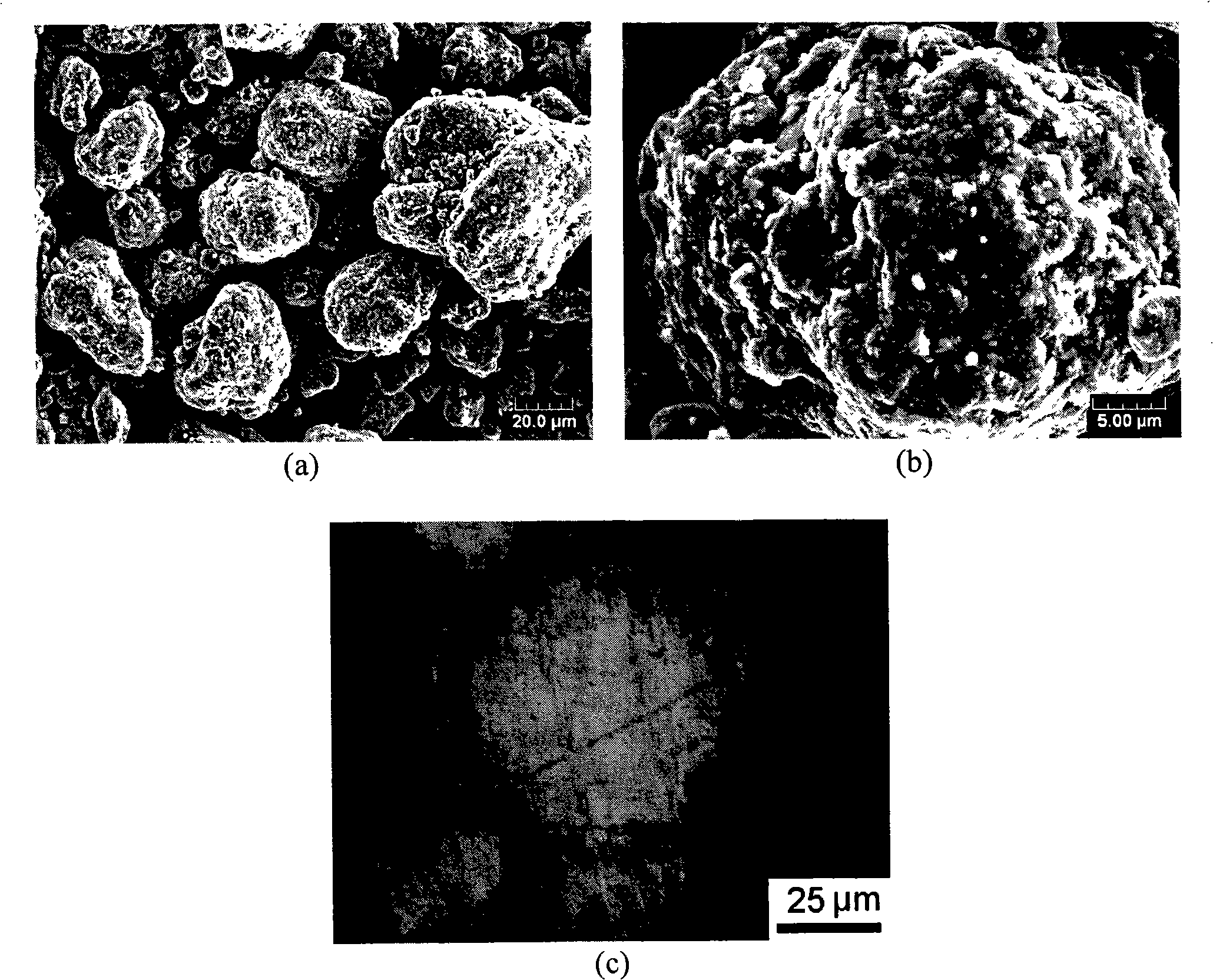

[0029] After the powder is mechanically mixed, take it out and add it to the stainless steel ball mill tank of the planetary ball mill. The grinding balls are stainless steel balls with a diameter of 30mm, and the ratio of stainless steel balls to powder is approximately 11:40 (5 grinding balls and 400g powder), without any protective atmosphere. The revolution and rotation speed of the stainless steel ball mill tank is both 300rpm. ...

Embodiment 2

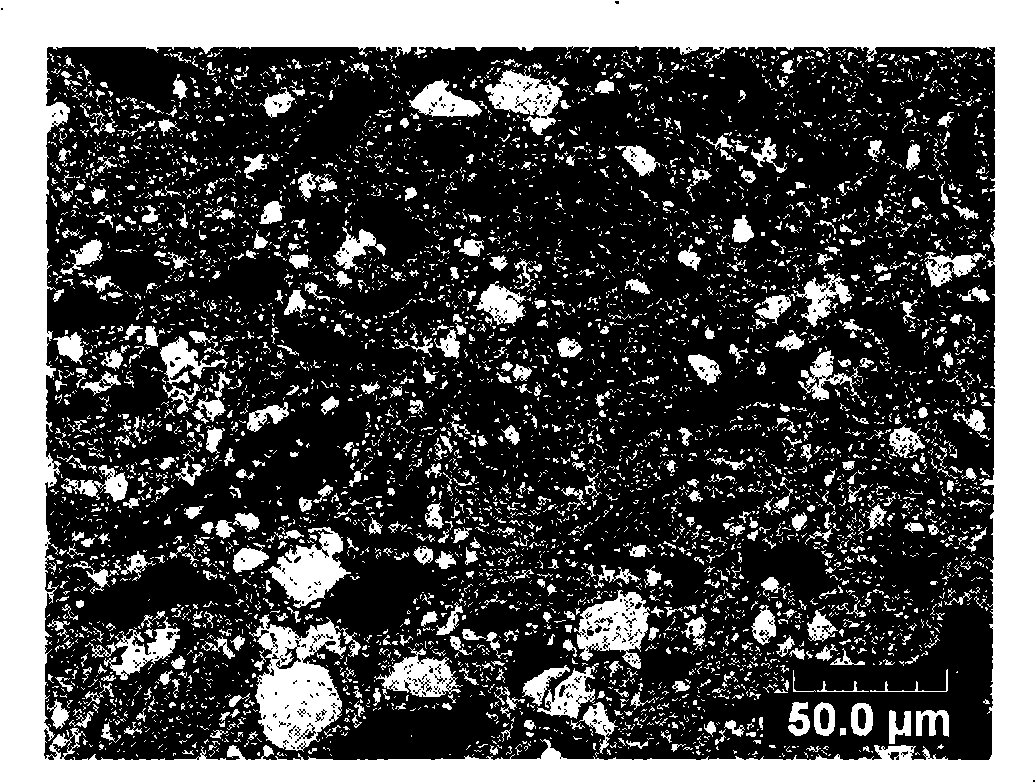

[0033] Adopt the ball-milled powder in embodiment example 1. Choose an aluminum alloy ring with an outer diameter of 50mm, a thickness of 4mm, and a length of 100mm as the substrate, and use 24-mesh white corundum sand for surface roughening before cold spraying. The working gas for cold spraying is compressed air, the gas pressure at the inlet of the spray gun is 2.7MPa, and the gas temperature is about 500°C; the powder feeding gas is argon, the pressure is 3.0MPa, and the flow rate is 40NL / min; the powder feeding speed is about 20g / min; the spraying distance 50mm; the spray gun is clamped by the manipulator, the up and down movement speed is 10mm / s, and the up and down movement distance is 50mm; the substrate rotation speed is 100rpm. After spraying, a coating with a thickness of about 30mm is obtained, the cross section is trapezoidal, the bottom is 54mm (coating and substrate interface), and the top is about 37mm (coating surface).

[0034]It should also be pointed out t...

Embodiment 3

[0036] Select the metal matrix material as tin bronze alloy powder (Cu-8wt%Sn), and the particle size of the powder is 5-63 μm; select Al 2 o 3 The powder is hard phase particles with a particle size of 5-45μm; Cu-8wt%Sn is basically spherical, Al 2 o 3 is an irregular polygon. The Cu-8wt%Sn powder and Al 2 o 3 Powder according to weight ratio 30wt% (volume ratio 48.5vol%Al 2 o 3 ) after mixing, put it into a plastic bottle, and then mix it with a powder mixer for 30 minutes. After the powder is mechanically mixed, take it out and add it to the stainless steel ball mill tank of the planetary ball mill. The grinding balls are stainless steel balls with a diameter of 30mm, and the ratio of stainless steel balls to powder is approximately 11:40 (5 grinding balls and 400g powder), without any protective atmosphere. The revolution and rotation speeds of the stainless steel ball mill tank are both 300rpm. The ball mill adopts the working method of half an hour of ball millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com