Direct writeTM system

a writetm system and material technology, applied in the direction of superimposed coating process, liquid/solution decomposition chemical coating, manufacturing tools, etc., can solve the problem of limiting the variety of materials which may be deposited, so as to achieve the effect of enhancing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. Direct Write™ Methods & Apparatus

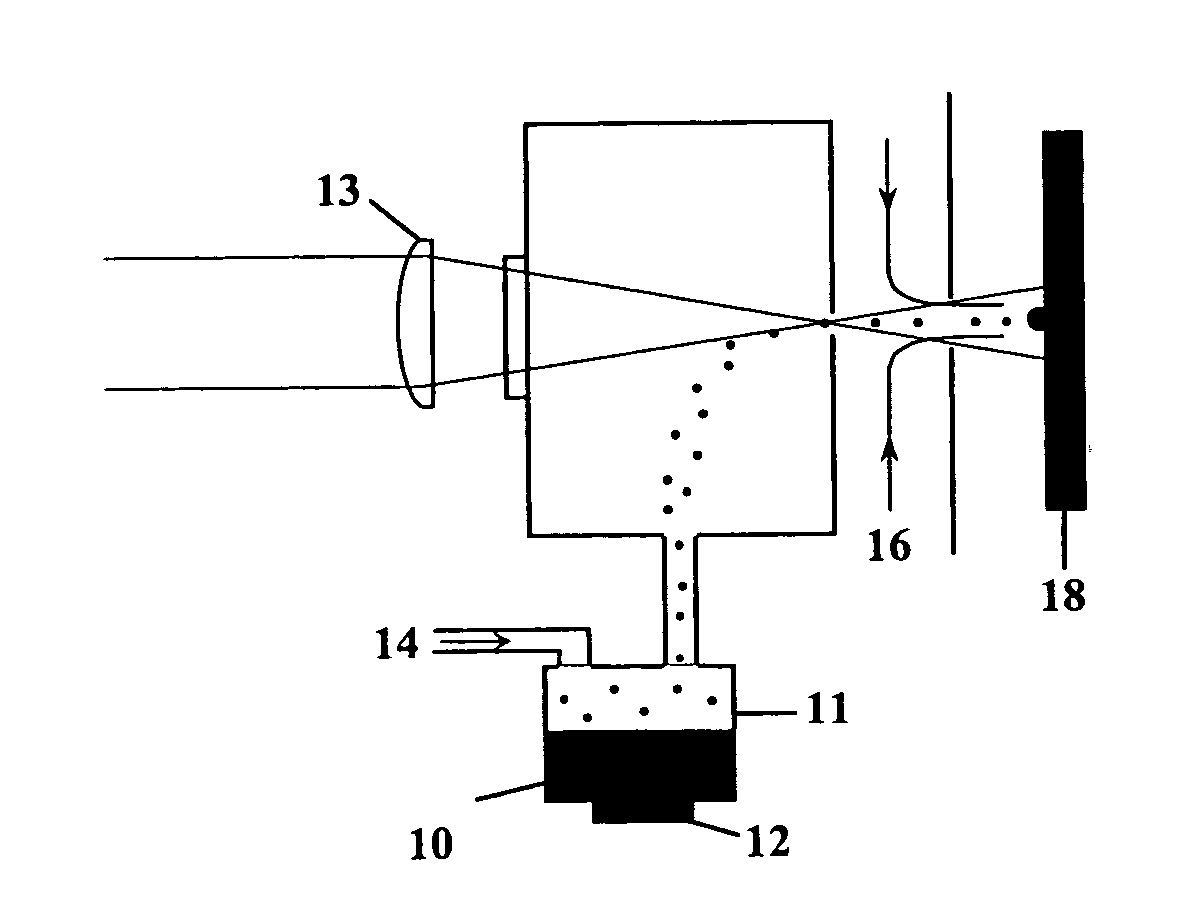

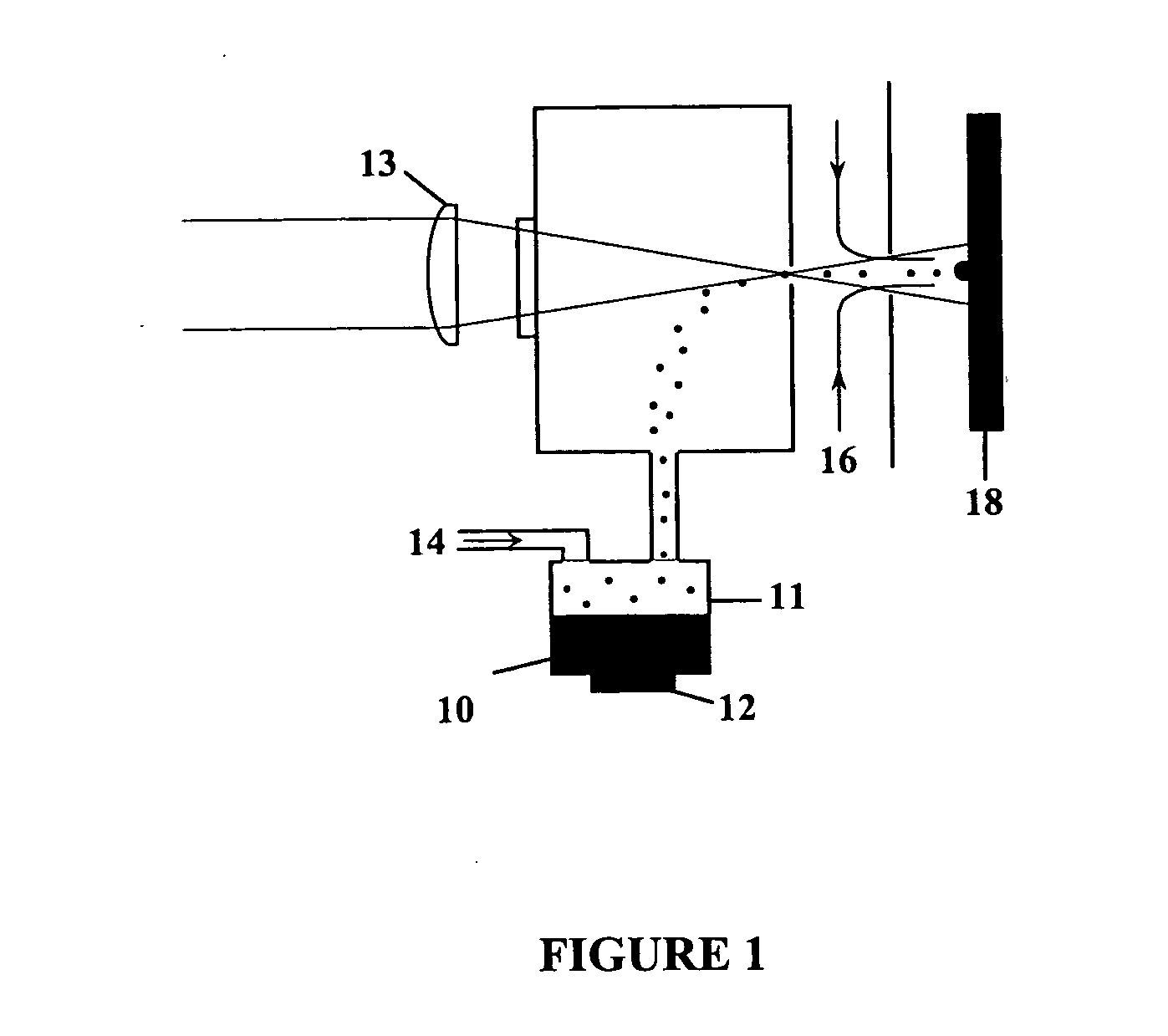

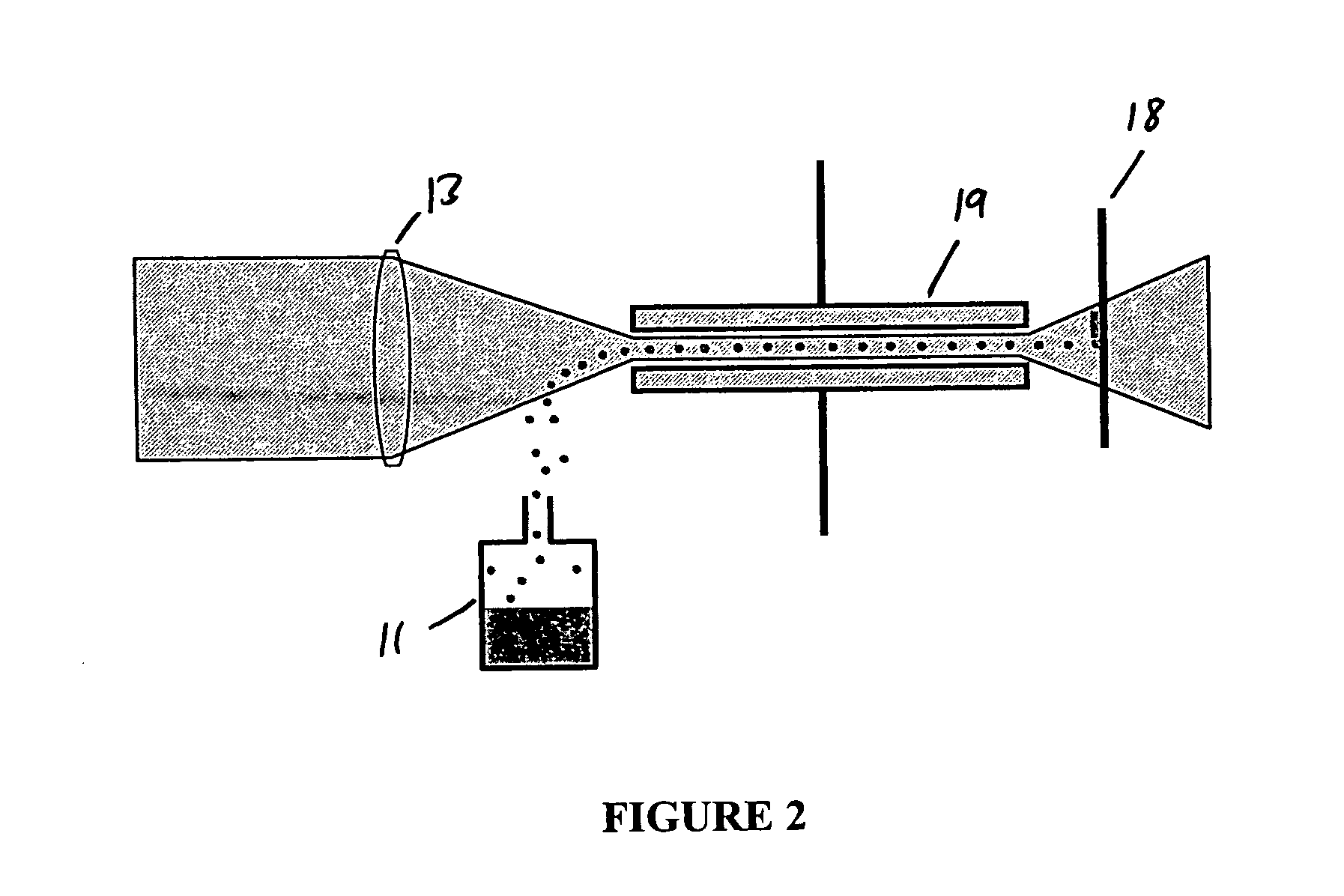

[0045]FIG. 1 presents a a schematic view of one of the preferred embodiments of the Direct Write™ System, which comprises methods and apparatus for maskless, mesoscale deposition of a source material on a substrate. Unlike many previous deposition systems which are restricted to the formation of planar layers on a flat substrate, the present invention is capable of forming a wide variety of planar, non-planar, conformal or three-dimensional features on a substrate having virtually any profile or topography.

[0046] In one embodiment, the invention comprises a source of material 10 contained by an enclosure 11. Although the a preferred embodiment generally includes a source material in liquid form, the source may comprise any aggregation, mixture, suspension or other combination of any materials in any physical phase. The source of material 10 is contained in a vessel, pool, volume or chamber which is coupled to or in communication with an atomizer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| feature size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com