Cylindrical fixed member of thread-groove exhaust unit and vacuum pump using same

A technology of fixing parts and threaded grooves, which is applied to the parts, pumps, and pump components of pumping devices for elastic fluids, can solve the problems of destruction torque and high price of vacuum pumps, and achieve the effect of improving exhaust performance and compression performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings.

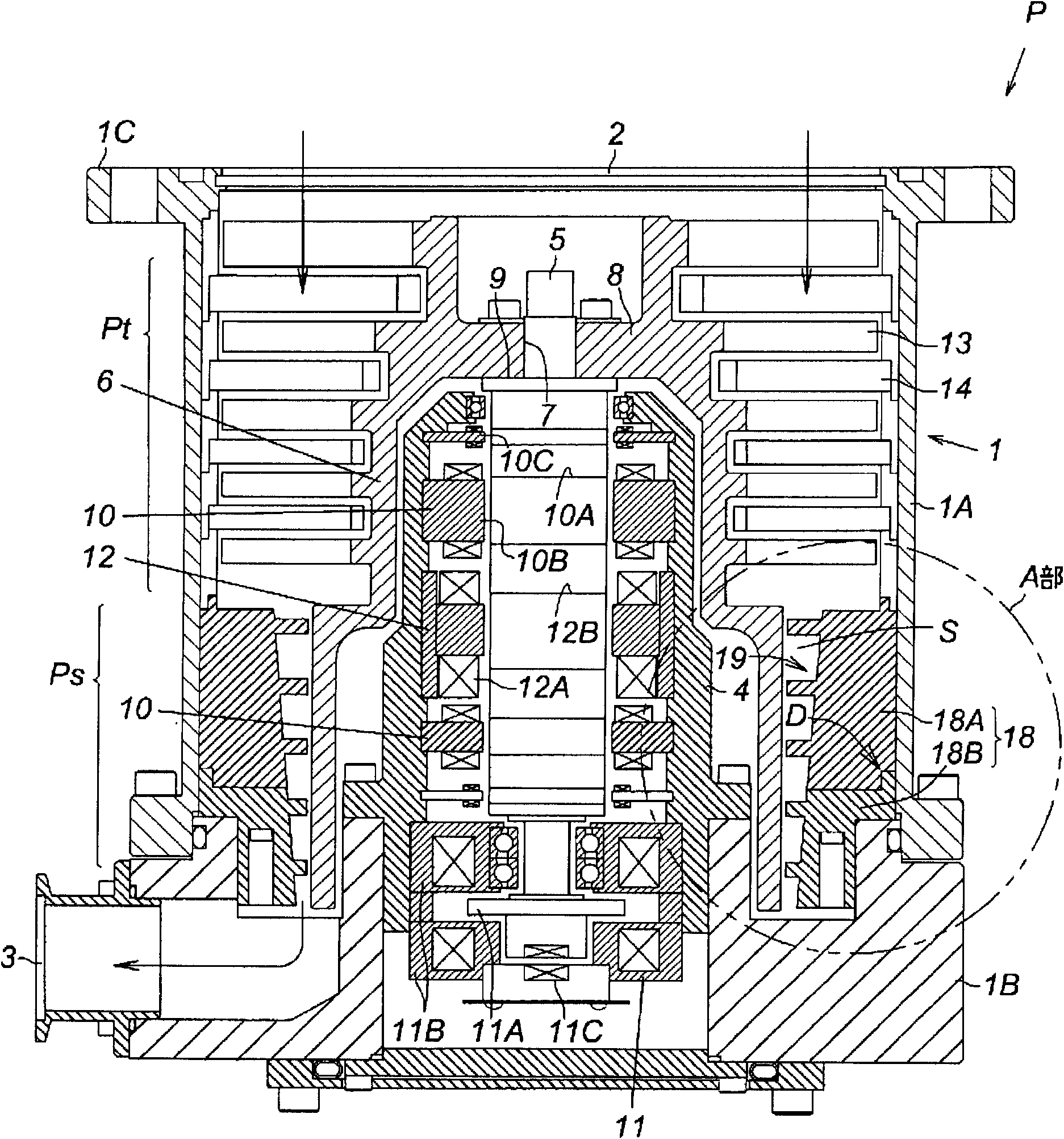

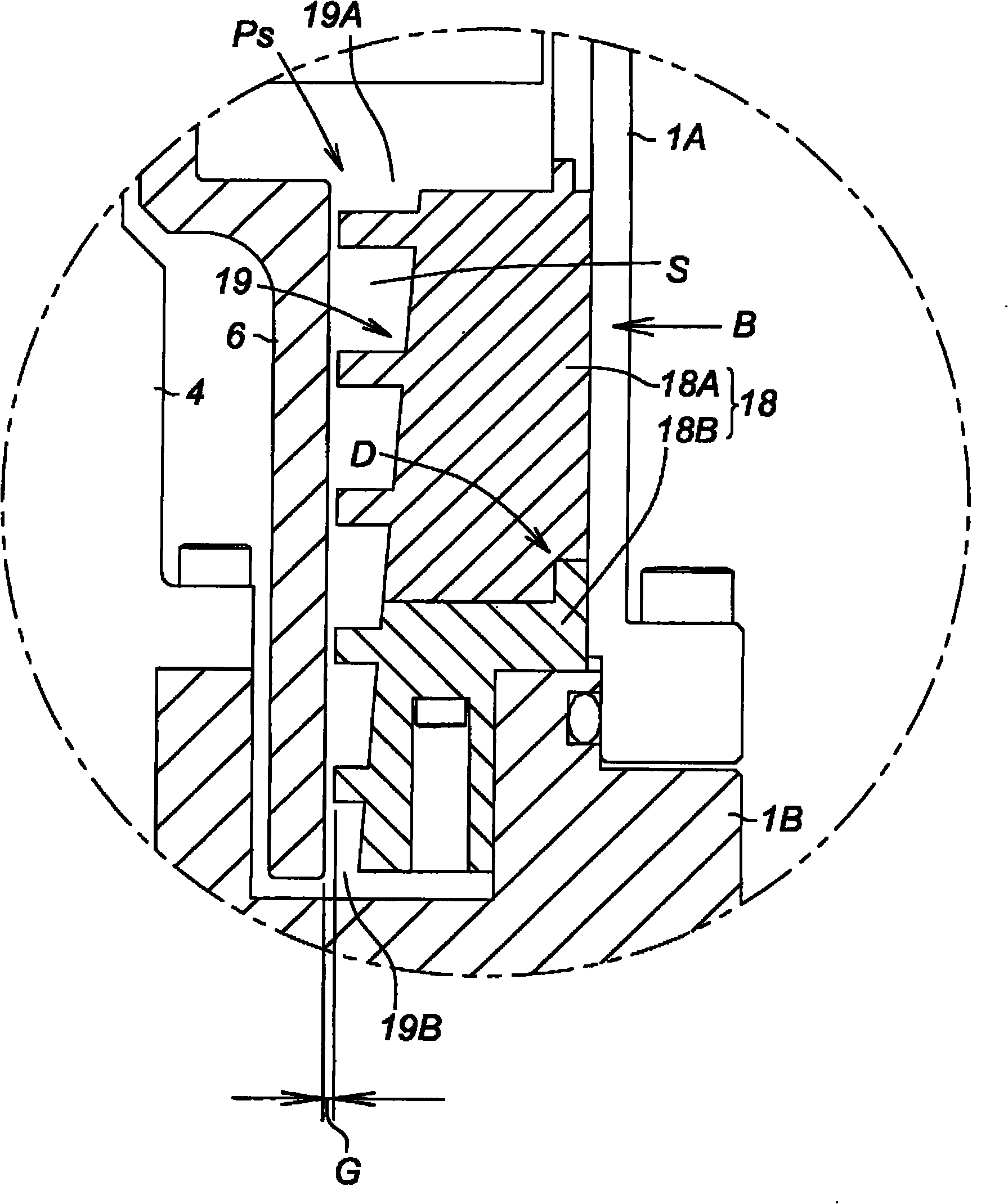

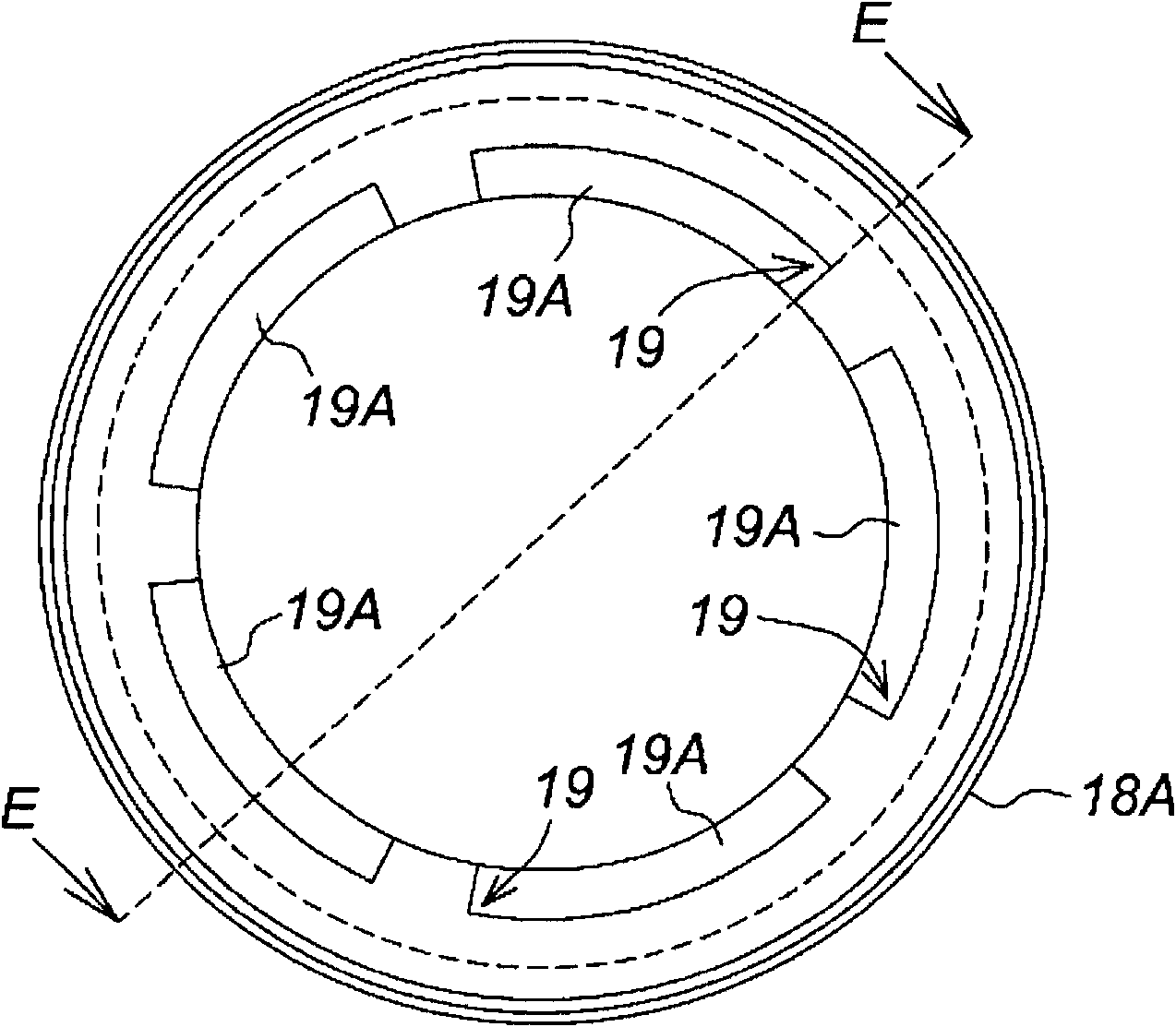

[0050] figure 1 It is a cross-sectional view of a vacuum pump using a cylindrical fixing member of a screw groove exhaust part according to an embodiment of the present invention, figure 2 yes figure 1 Enlarged view of part A in, image 3 It is a plan view of the thread groove exhaust stator (fixed part of the thread groove exhaust part), Figure 4 yes image 3 E-E cutaway view.

[0051] figure 1 The vacuum pump P in is used, for example, as a part of a vacuum device on a semiconductor manufacturing device or a liquid crystal display panel manufacturing device, and sets the pressure in the vacuum container to a predetermined vacuum degree.

[0052] The vacuum pump P in this figure is provided in the outer casing 1: a wing exhaust part Pt that discharges gas through the rotary blade 13 and a fixed blade 14, and a screw groove row that dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com