Assembly technology of precise cycloidal speed reducer

An assembly process and reducer technology, which is applied in transmission devices, gear transmission devices, belts/chains/gears, etc., can solve the problems of the performance impact of the whole machine, the meshing status of the rollers, and the complexity of the structure, so as to improve the assembly quality, The effect of reducing the difficulty of assembly and improving the precision of tolerance fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

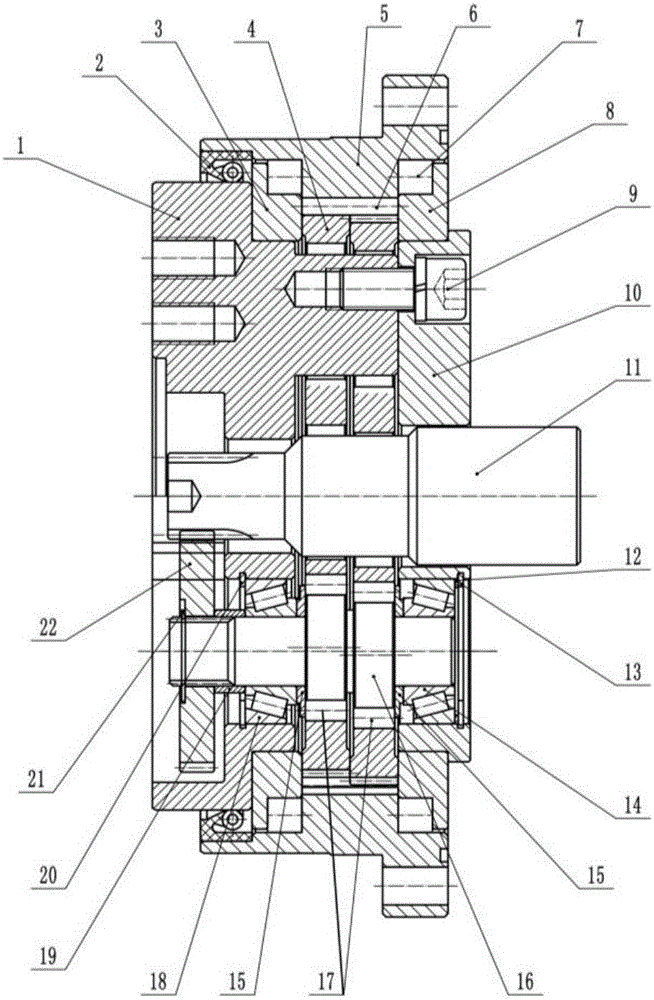

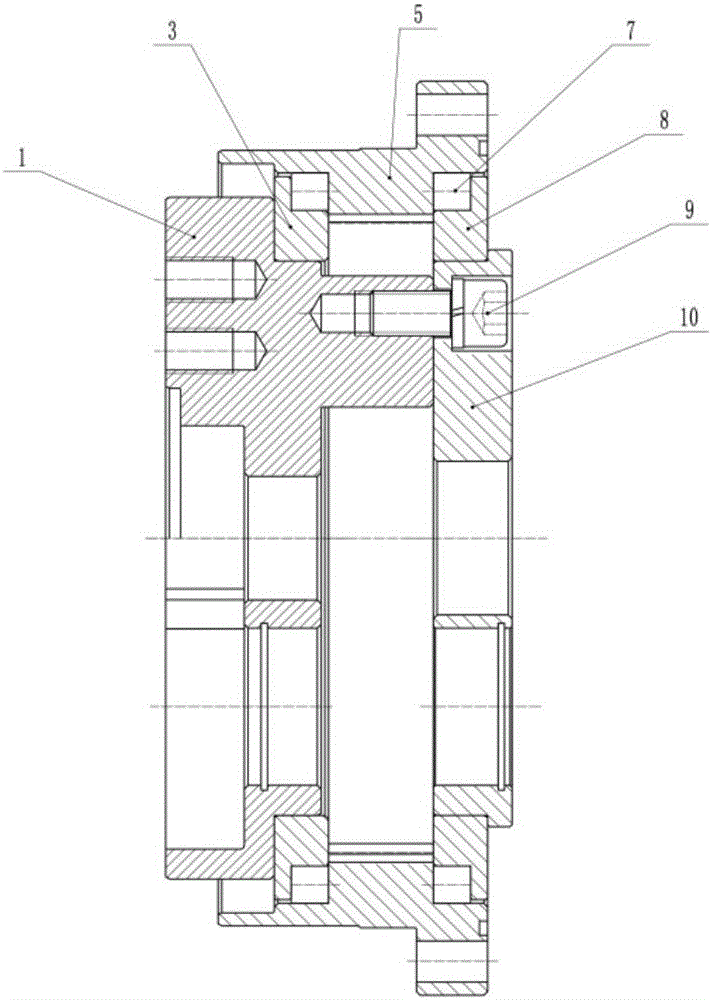

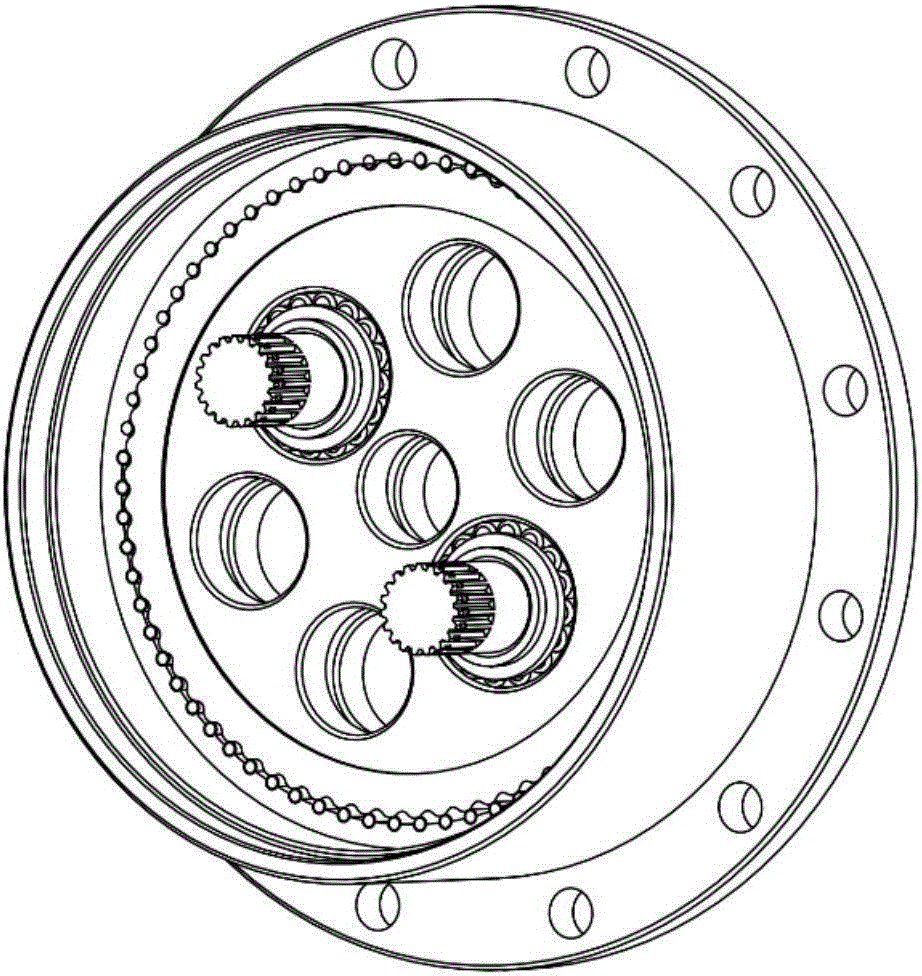

[0031] Embodiment 1. The crankshaft roller bearing of this embodiment is a full complement cylindrical roller bearing, and the support bearing is a raceway cross roller bearing, and the raceway of the cross roller bearing is integrated in the support mechanism and the internal gear. Its assembly process includes the following steps:

[0032] A. Grouping: Check the eccentric part of the crank shaft 16, the 4 coordinate holes of the circular gear, and the diameter of the pin teeth 6, group and number them; put the pin teeth 6 into the freezer to reduce the temperature of the pin teeth to -5~-20 ℃;

[0033] B. Crankshaft and Yuanli gear assembly: select the crankshaft 16 and Yuanli gear 4 with corresponding tolerances, and select the crankshaft roller 17 corresponding to the group number; Figure 5 As shown, put the crankshaft roller 17 into the full complement cylindrical roller assembly tool; then as Figure 4 As shown, put the crankshaft 16 and the crankshaft roller into the...

Embodiment 2

[0042] Embodiment 2. The crankshaft roller bearing of this embodiment is a cylindrical roller bearing without inner and outer rings with a cage, and the support bearing is a tapered roller bearing. The assembly process includes the following steps:

[0043] A. Grouping: Inspect the 16 eccentric parts of the crankshaft, the 4 coordinate holes of the circular gear, and the 6 diameters of the pin teeth, group and number them;

[0044] B. Put the needle teeth 6 and the crankshaft 16 into the freezer to reduce the temperature of the parts to -5~-20°C, select the circular gear 4 and the crankshaft roller 17 grouped with corresponding tolerances; place the crankshaft with the cage Put the roller 17 into the eccentric part of the crankshaft 16, quickly install the tapered roller bearing I, the tapered roller bearing II and the stopper 15 at both ends of the crankshaft; then put the crankshaft into the coordinate hole of the circular gear to ensure The crank shaft and the coordinate ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com