Device and method for measuring built-in low-temperature pumping speed

A measuring device, cryogenic pump technology, applied in pump testing, pumps, liquid variable capacity machinery, etc., can solve problems such as not eliminating, the diffuser can not well solve the effect of imported gas jet, and the gas supply method is outdated. , to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

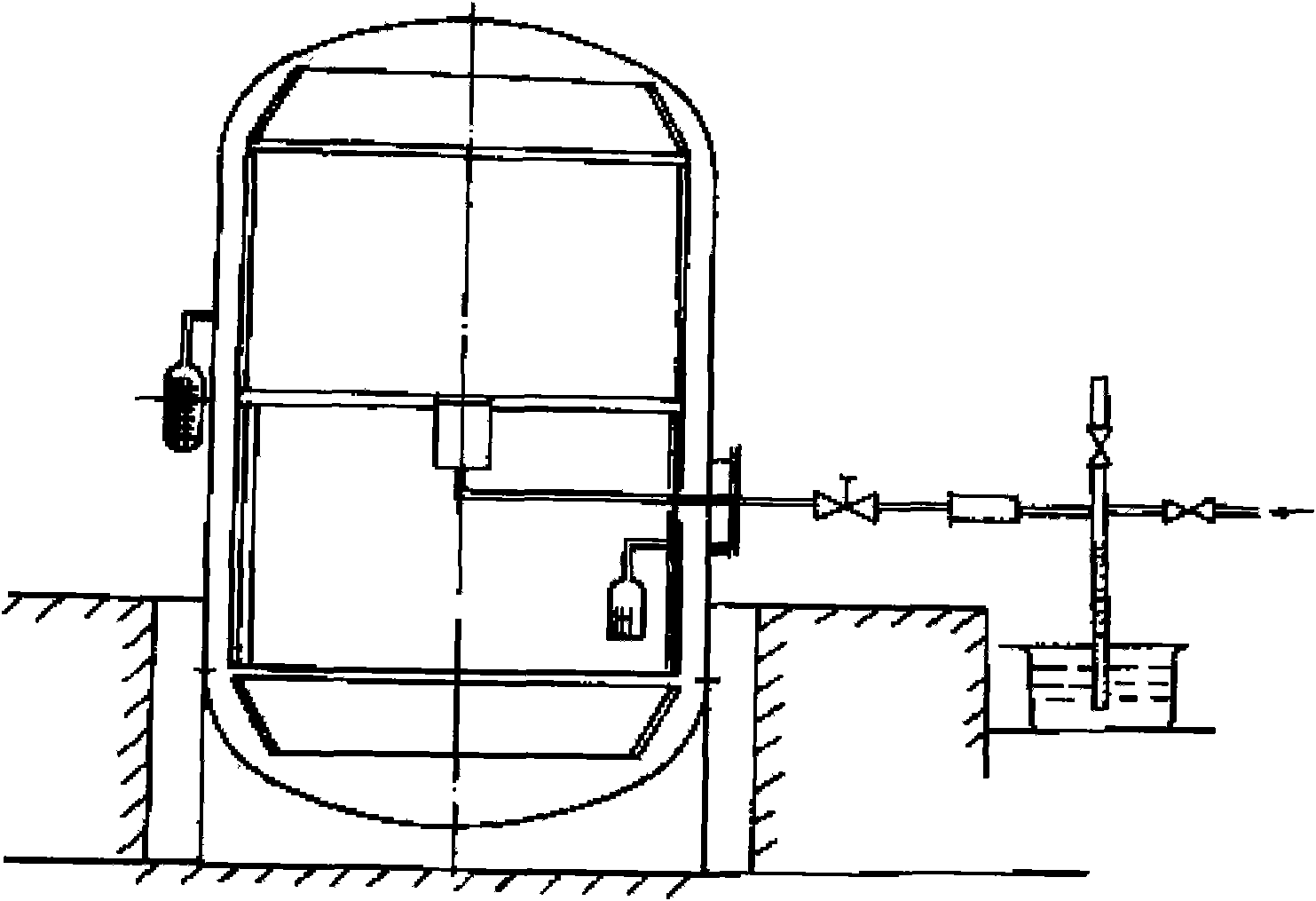

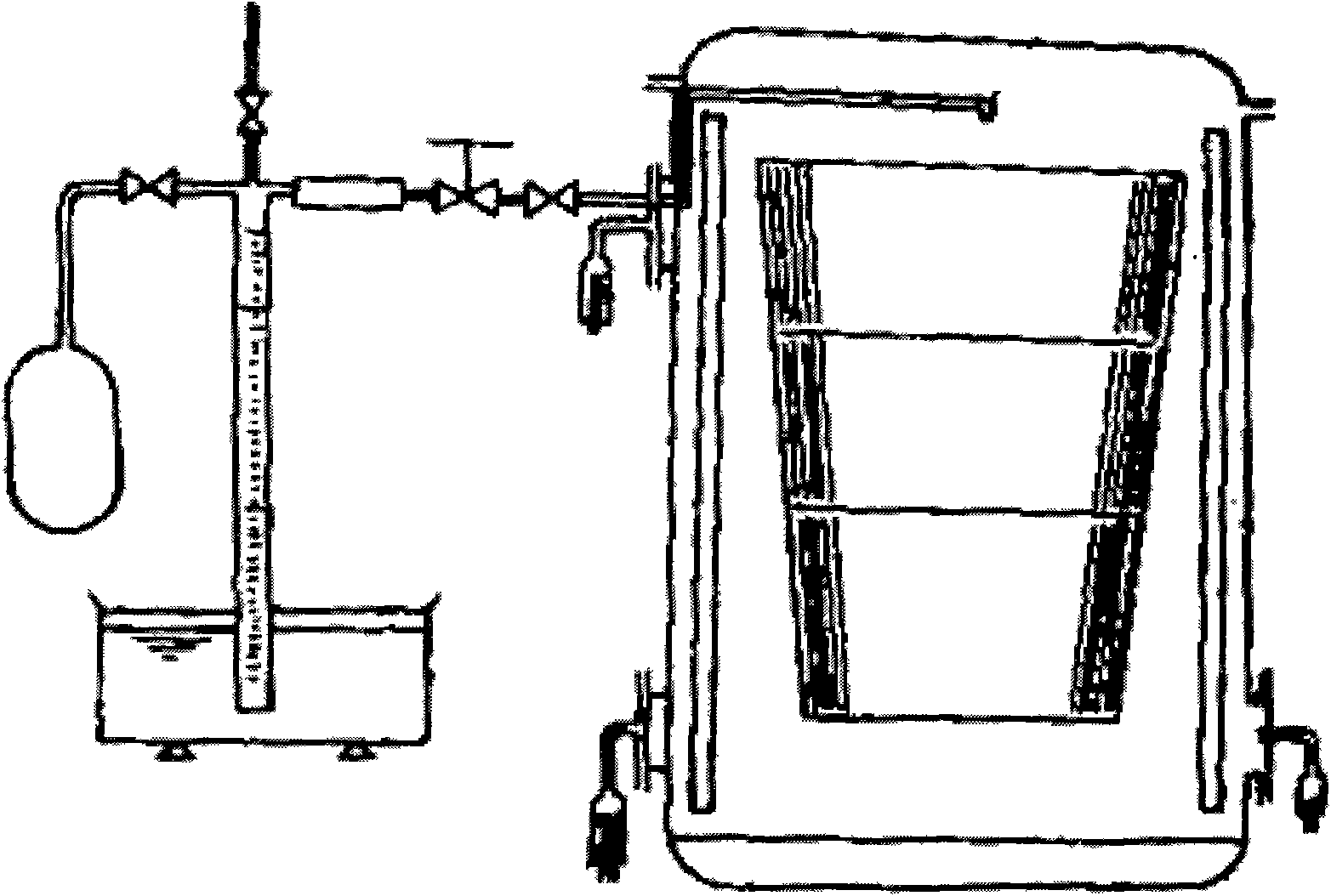

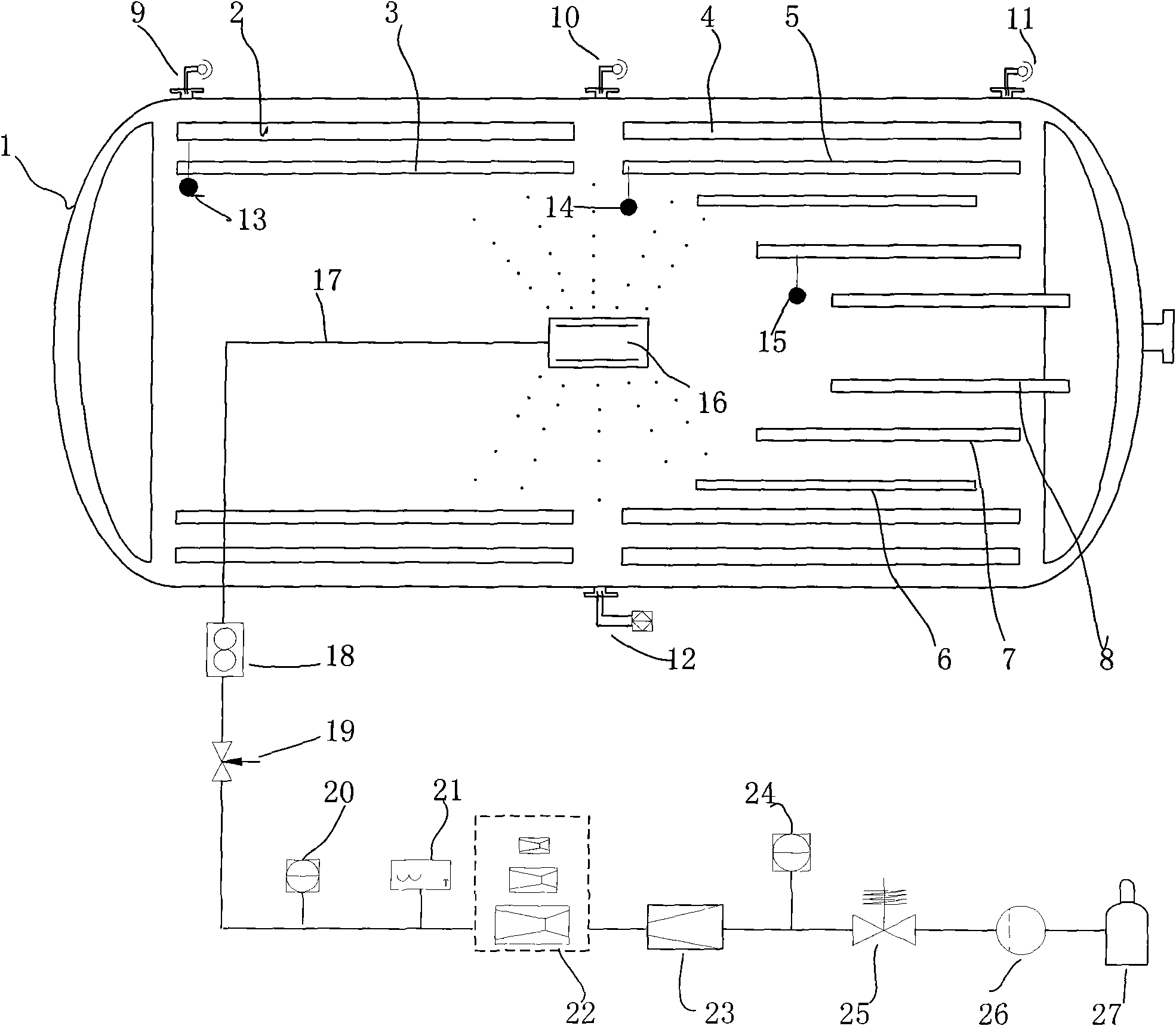

[0040] The device and method for measuring the pumping speed of a built-in cryogenic pump apply the concept of measuring the pumping speed of a traditional pump by the constant pressure method to the measuring of the pumping speed of a large built-in cryopump, and use the entire vacuum container as a test cover. See attached image 3 As shown, the biggest feature of this measurement method is to use a pressure reducer with a sonic nozzle to precisely adjust the volume flow rate of the introduced gas, and make the introduced gas evenly spread to the surface of the cold plate of the built-in cryopump through the diffuser (16).

[0041]After the test gas comes out of the gas cylinder (27), it is first filtered by the filter (26), and then decompressed by the pressure reducer (23), the high-pressure gas is changed to 1 standard atmospheric pressure, and the gas flows through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com