Calibration device for sonic nozzle gas flowmeter by positive-pressure method and application method

A gas flow meter and sonic nozzle technology, applied in the field of flow meter calibration, can solve the problems of huge device system, huge investment and operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

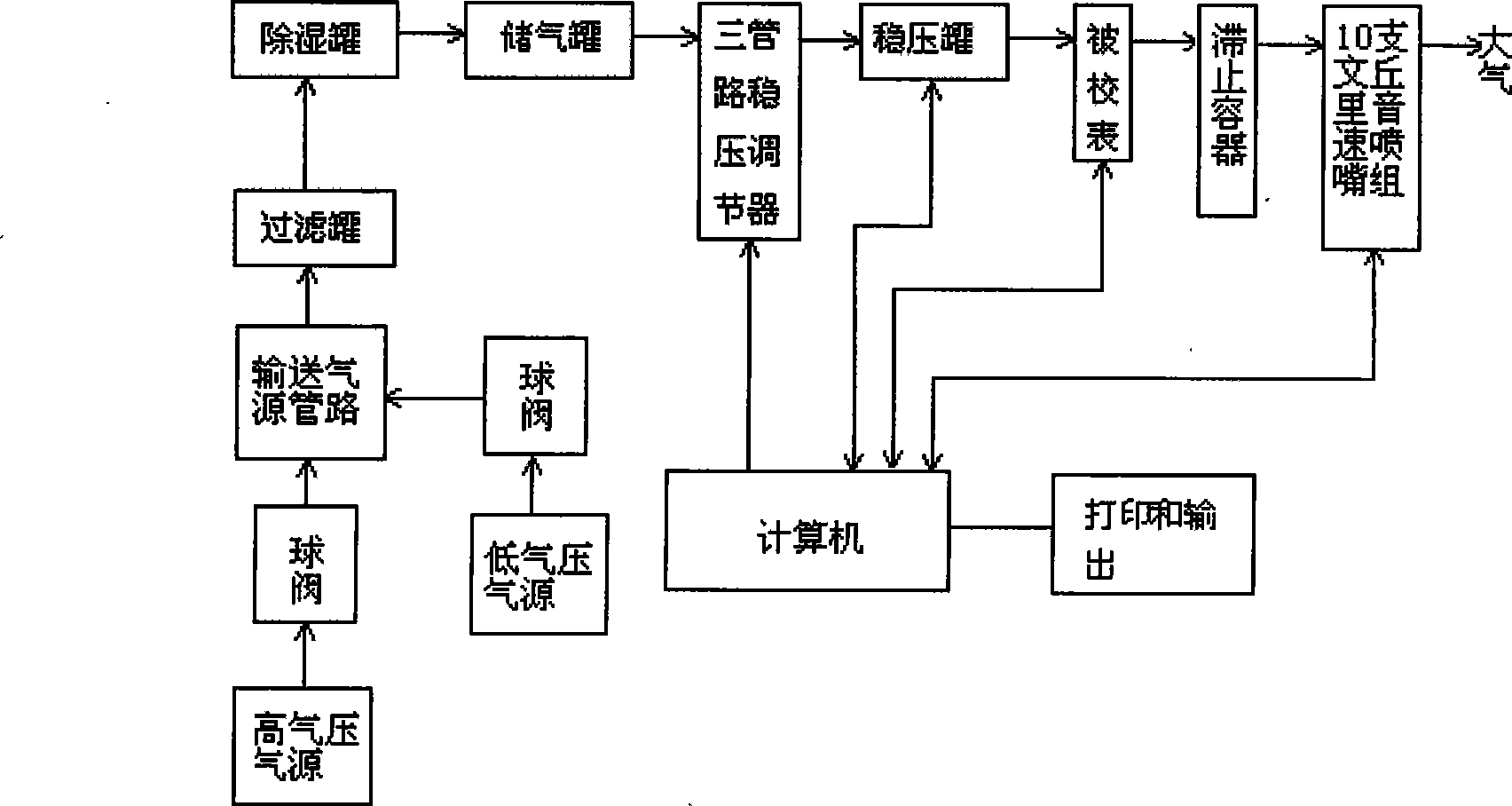

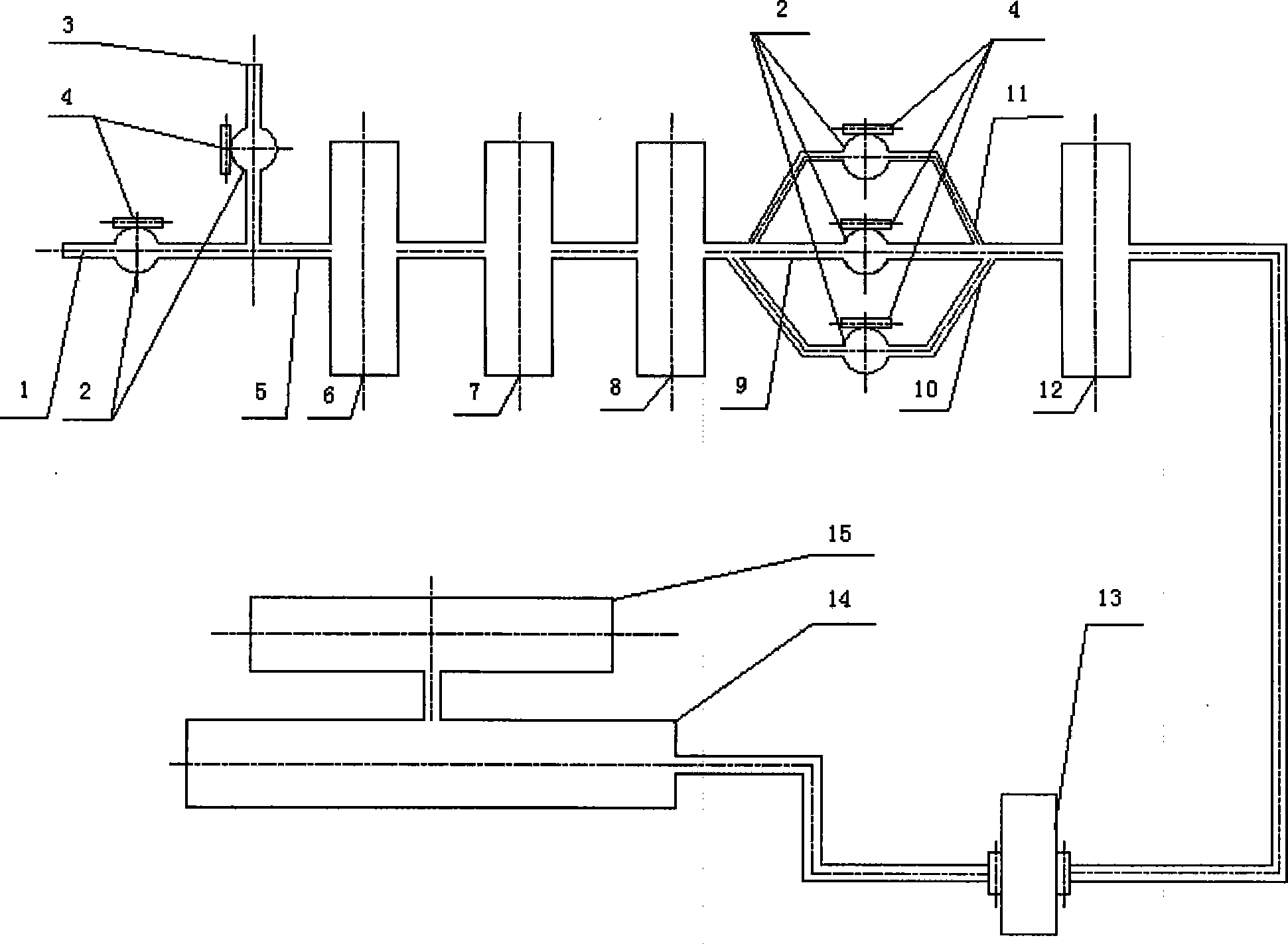

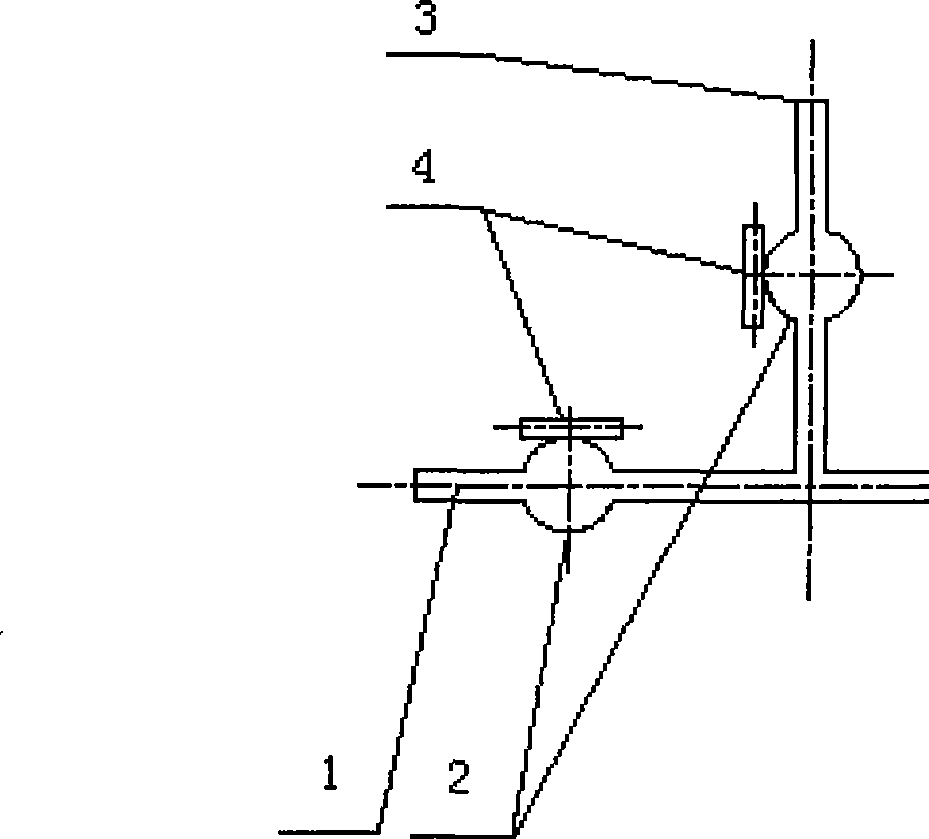

[0045] Such as figure 2 As shown, the device includes a ball valve 2, a solenoid valve 4, a filter tank 6, a dehumidification tank 7, an air storage tank 8, a pressure regulator tank 12, and a stagnation container 14, at the entrance of the high-pressure gas pipe 1 and the entrance of the low-pressure gas pipe 3 Ball valves 2 are installed respectively, and a solenoid valve 4 is installed on the ball valve 2. The solenoid valve 4 is connected to the computer, and the low-pressure gas pipe 3 and the high-pressure gas pipe 1 are connected to the gas supply pipeline 5 at the same time. A three-pipe regulator is installed between the gas storage tank 8 and the surge tank 12, and three pipelines with different calibers are connected in parallel in the gas storage tank 9, medium-bore pipeline 10, and thin-bore pipeline 11. Between the tank 8 and the surge tank 12, a ball valve 2 is installed on each pipeline, and a solenoid valve 4 is installed on the ball valve 2. The solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com