Continuously-adjustable sonic nozzle

A technology of sonic nozzle and valve body, applied in the direction of lift valve, valve details, engine components, etc., can solve the problems of difficult to change, cannot be used as a flow regulating device, and the flow is not easy to change, and achieves smooth transition, small operating force, and continuous flow. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

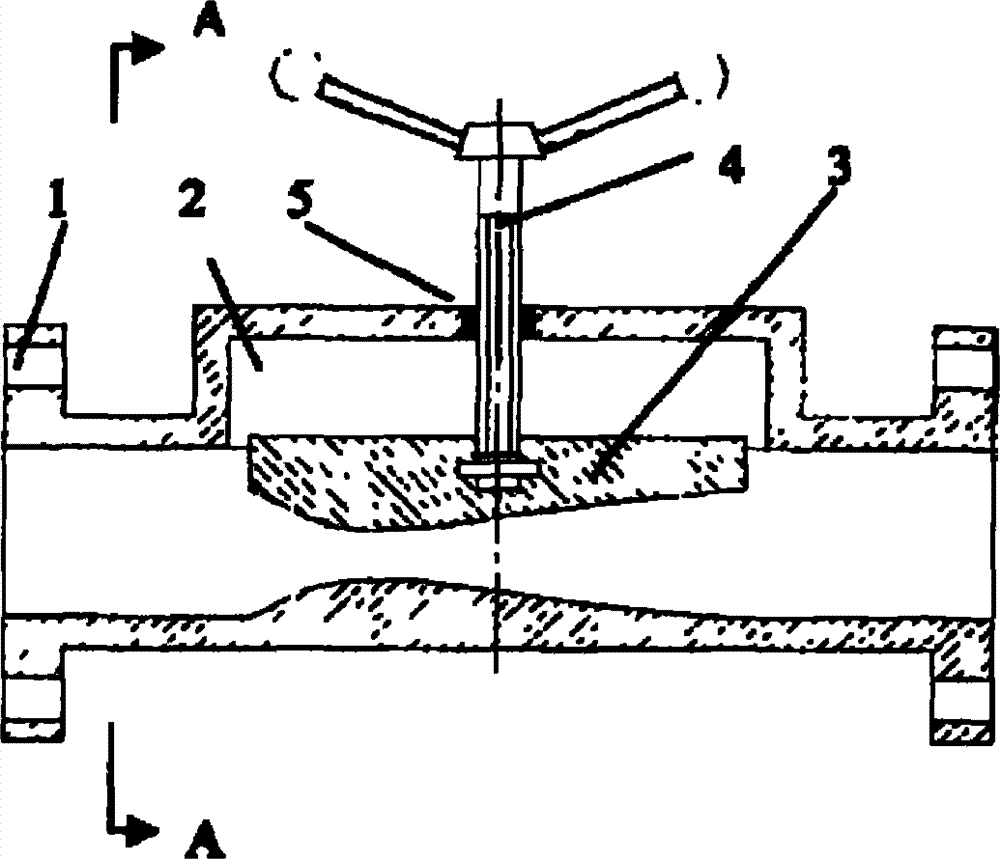

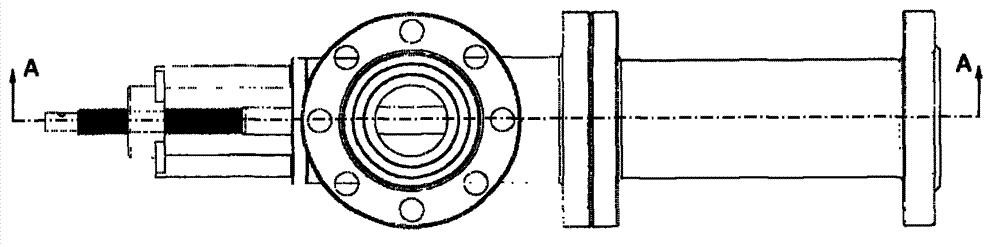

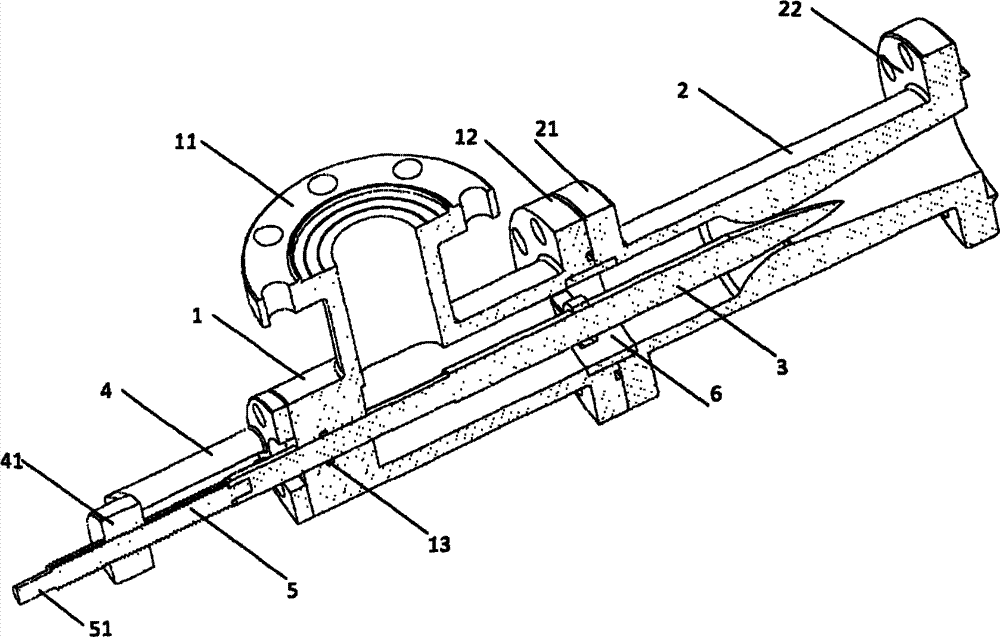

[0043] image 3 It is a schematic diagram of the overall structure of the present invention. The technical scheme adopted in the present invention is: adding a plug cone to the sonic nozzle with mature technology, and adjusting the throat area of the sonic nozzle through the plug cone, so as to realize the continuous adjustment of the flow rate without changing the upstream area. The invention comprises a valve body 1, a sonic nozzle 2, a plug cone 3 and a transmission device.

[0044] Figure 4 It is a sectional view of the sonic nozzle 2. The sonic nozzle 2 is a rotary body, and the inner profile is a straight inlet section 24, a circular arc convergence section 25, a straight throat section 26, and a straight expansion section 27. All adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com