Semiconductor device fabricating system and semiconductor device fabricating method

a technology of semiconductor devices and fabricating systems, which is applied in the direction of coatings, metallic material coating processes, chemical vapor deposition coatings, etc., can solve the problems of inability to achieve accurate flow rate control, difficult to adjust the flow rate of inert gas, and contamination of particles or gas supply lines, etc., to achieve accurate control and stably carried out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

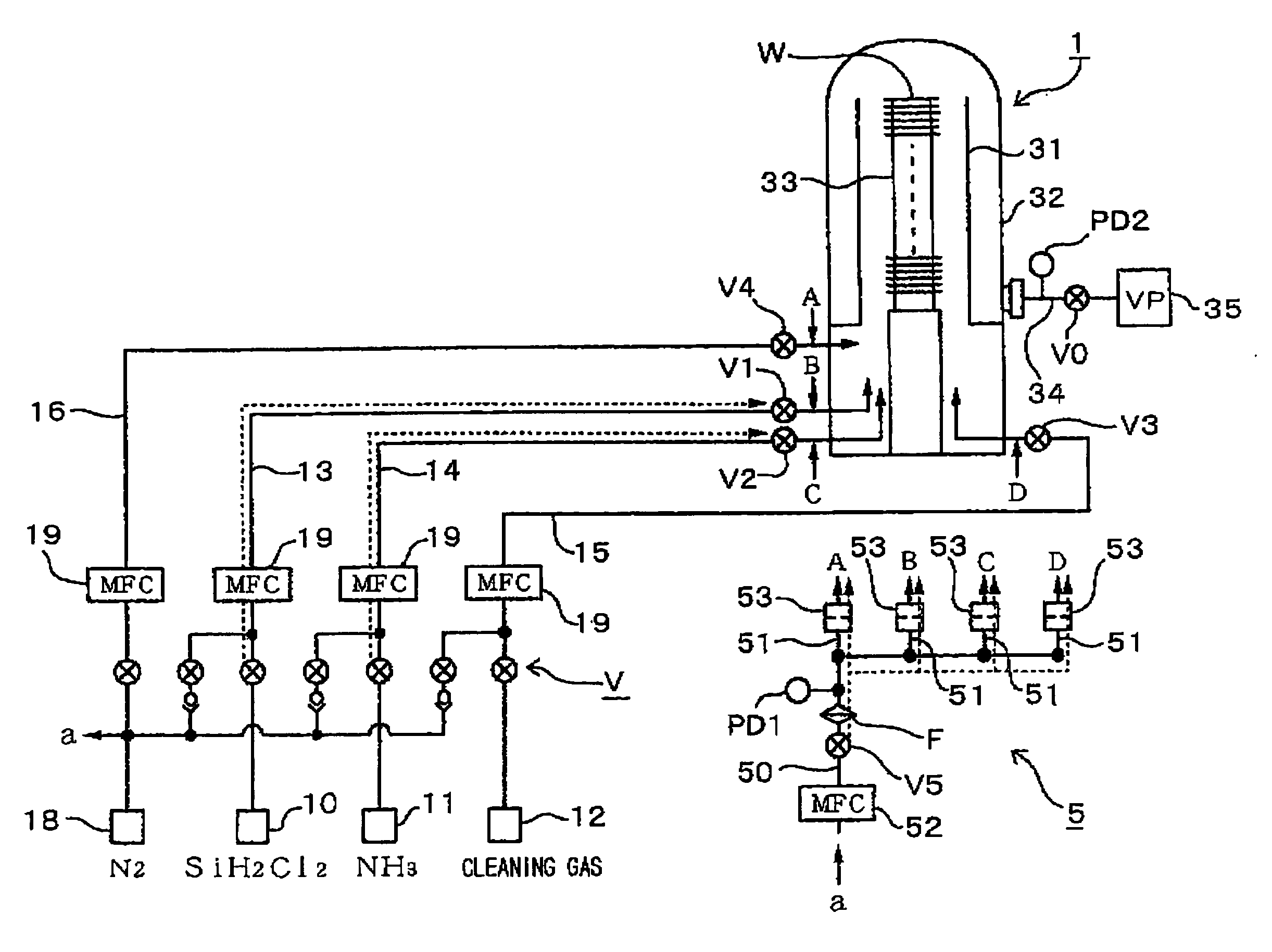

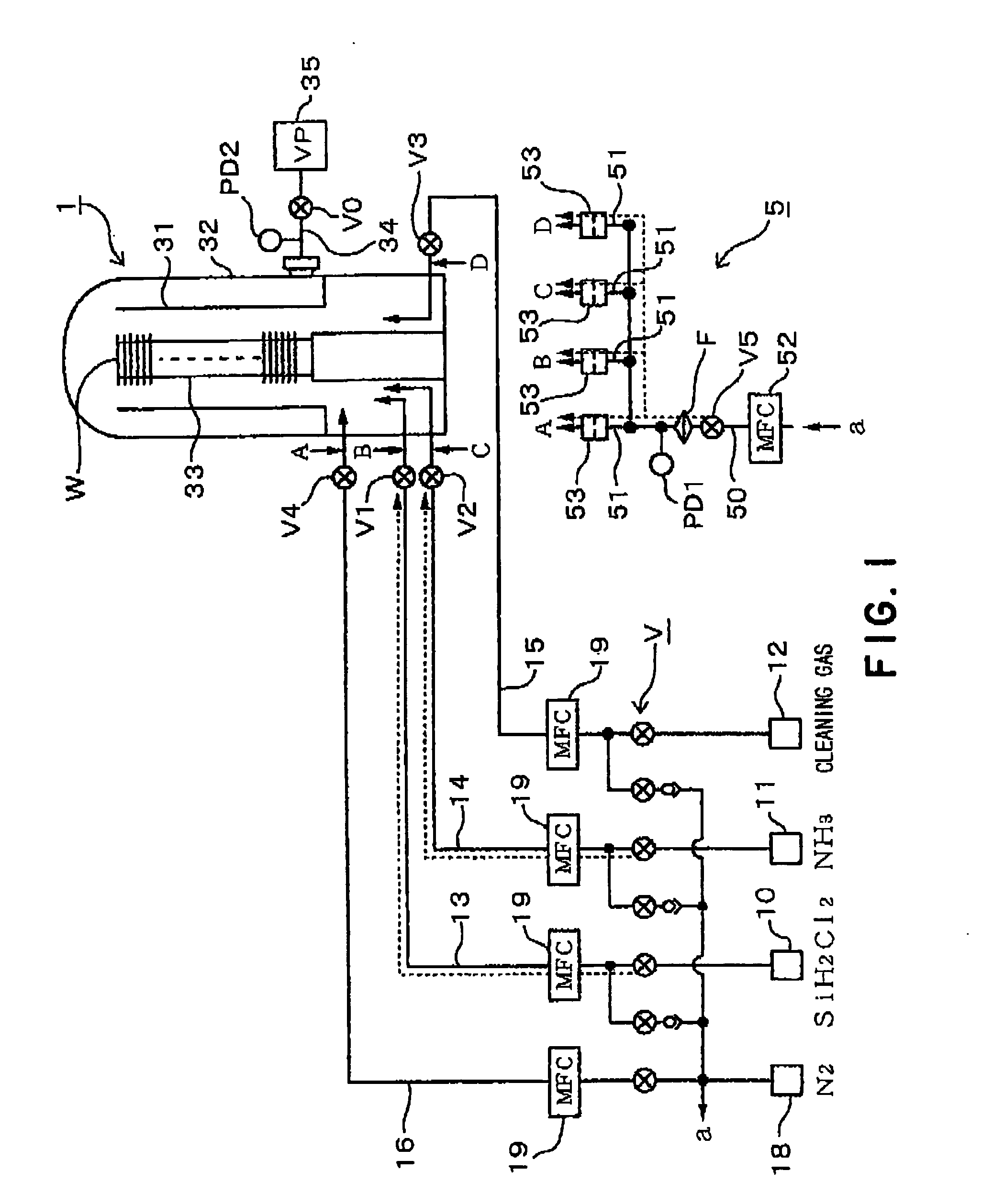

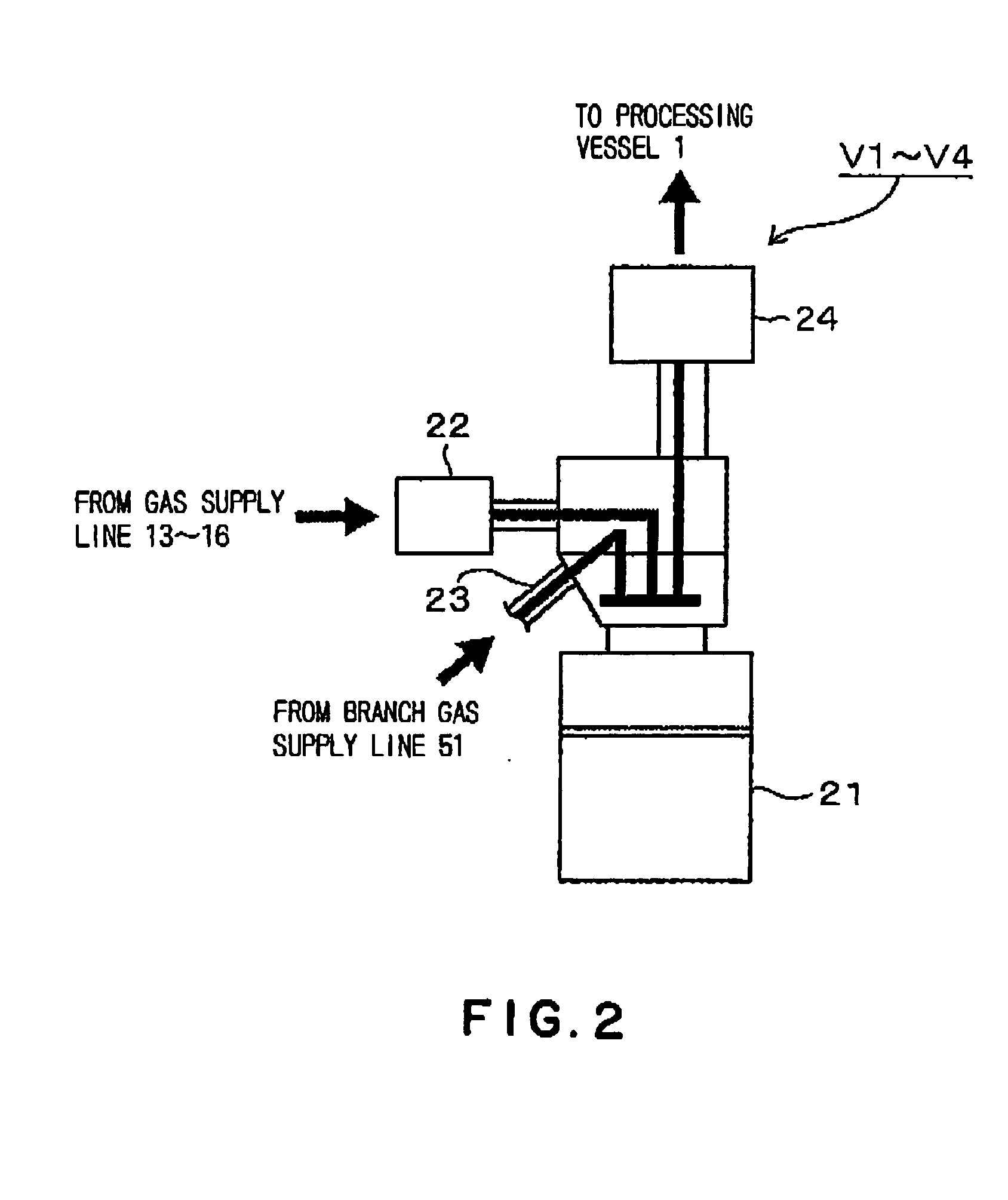

[0032]FIG. 1 shows a piping system included, in a vertical thermal processing system, namely, semiconductor device fabricating system, in a first embodiment according to the present invention. The vertical thermal processing system includes, as principal components; a processing vessel 1 for processing a semiconductor wafer, i.e., a substrate on which semiconductor devices are to be fabricated, by a thermal process, such as a film deposition process for depositing a film on the semiconductor wafer (hereinafter, referred to simply as “wafer”); three process gas sources 10, 11 and 12, i.e., a dichlorosilane source 10, an ammonia source 11 and a cleaning gas source 12; process gas supply lines 13, 14 and 15, i.e., a dichlorosilane supply line 13, an ammonia supply line 14 and a cleaning gas supply line 15, respectively connecting the process gas sources 10, 11 and 12 to the processing vessel 1; a discharge line 34 connected to the processing vessel 1; and a purge gas supply unit 5 for ...

second embodiment

[0050] A piping system included in a semiconductor device fabricating system in a second embodiment according to the present invention will be described with reference to FIG. 4. The piping system shown in FIG. 4 is provided with a flow control unit including a mass flow meter 54 and an automatic pressure regulator 55 instead of a mass flow controller for controlling the total flow rate of a purge gas flowing through branch purge gas supply lines 51. A controller, not shown, controls the automatic pressure regulator 55 arranged downstream of the mass flow meter 54 on the basis of a measured flow rate measured by the mass flow meter 54 to control the total flow rate of the purge gas for pressure control. The primary pressure on the primary side of orifices 53 is controlled to control the flow rates of the purge gas flowing through the branch purge gas supply lines 51.

third embodiment

[0051] In a piping system shown in FIG. 5 included in a semiconductor device fabricating system in a third embodiment according to the present Invention, mass flow controllers 58 are placed in branch purge gas supply lines 51, respectively, instead of the orifices 53. Since the purge gas is supplied at a low flow rate through the mass flow controllers 58 to parts of gas supply lines extending between a processing vessel 1 and shutoff valves V1 to V4 placed in the gas supply lines, the shutoff valves V placed on the gas supply lines not participating in a process may be kept closed. Therefore, the process gases used for the process and remaining in the gas supply lines can be replaced with the purge gas in a very short time before starting the next process and hence the next process can be started in a short time after the completion of the preceding process.

[0052] If the purge gas heated at temperatures in the range of, for example 100 to 200° C. by a heating device, not shown, is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com