Supersonic nozzle preventing from slag entrapment

A supersonic, anti-rolling slag technology, applied in the field of injection devices, can solve problems such as endangering production safety and life safety, and achieve the effects of improving oxygen utilization rate, promoting steel slag reaction, and enhancing penetrating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

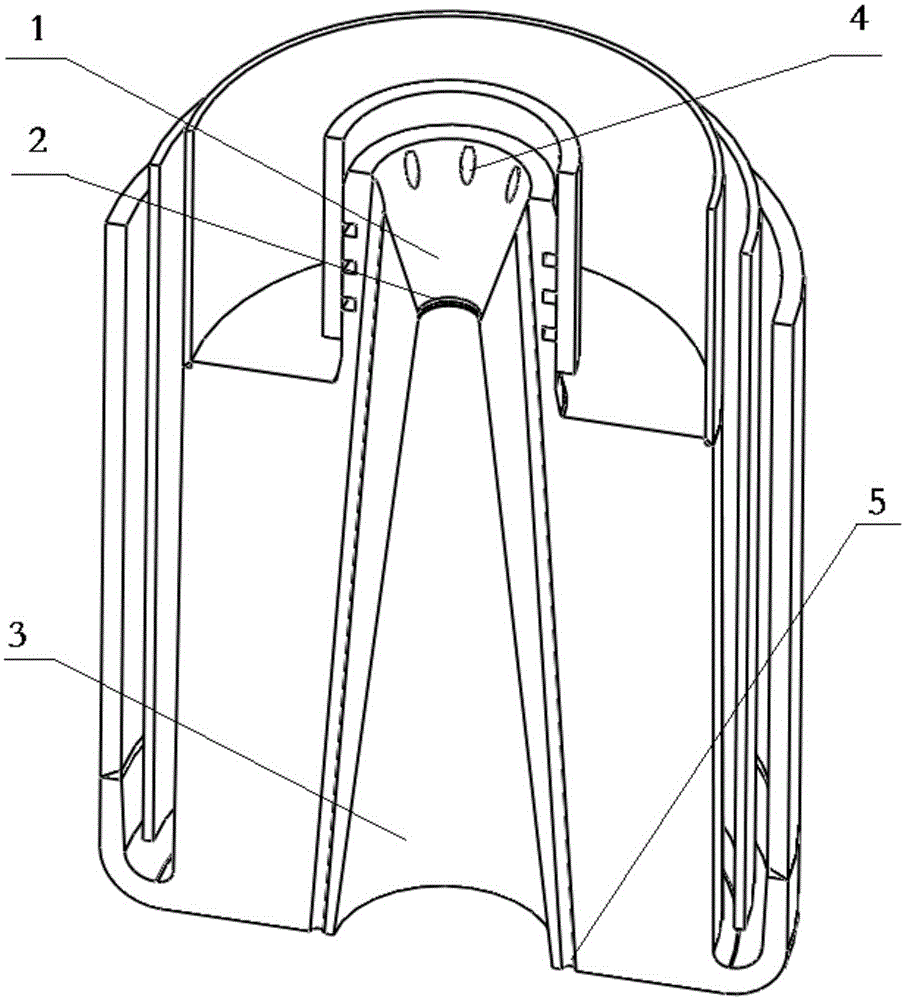

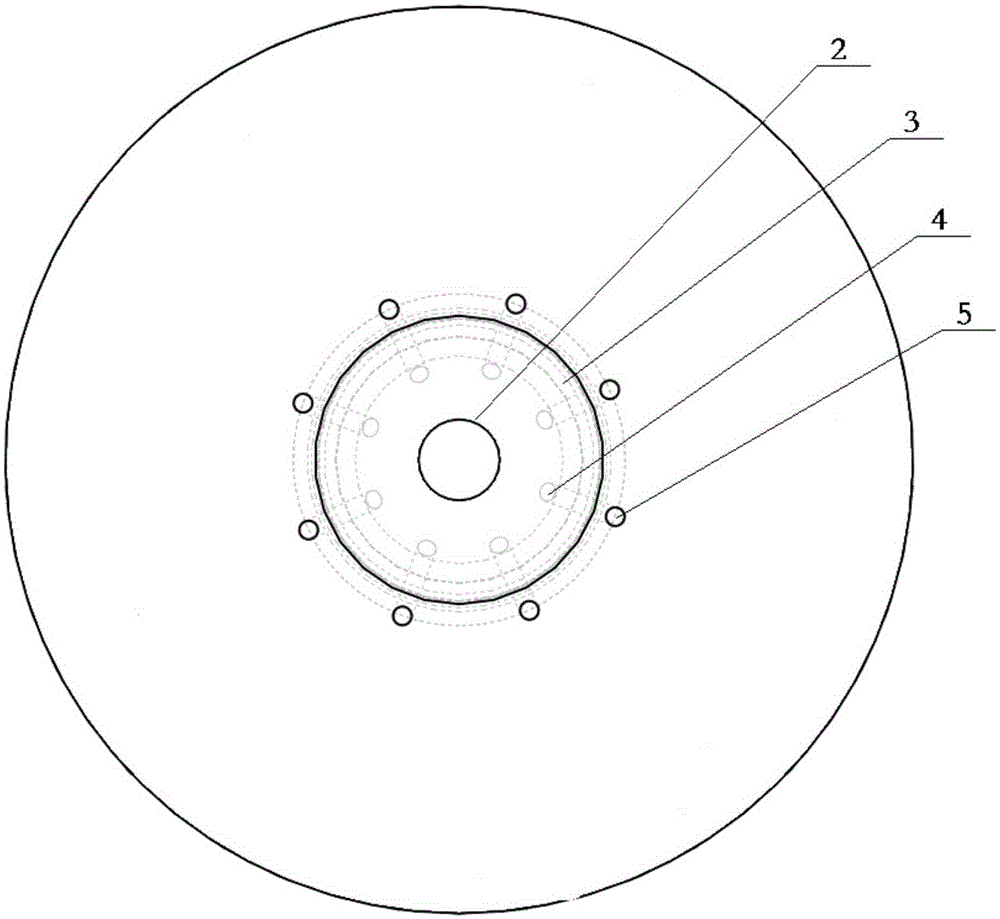

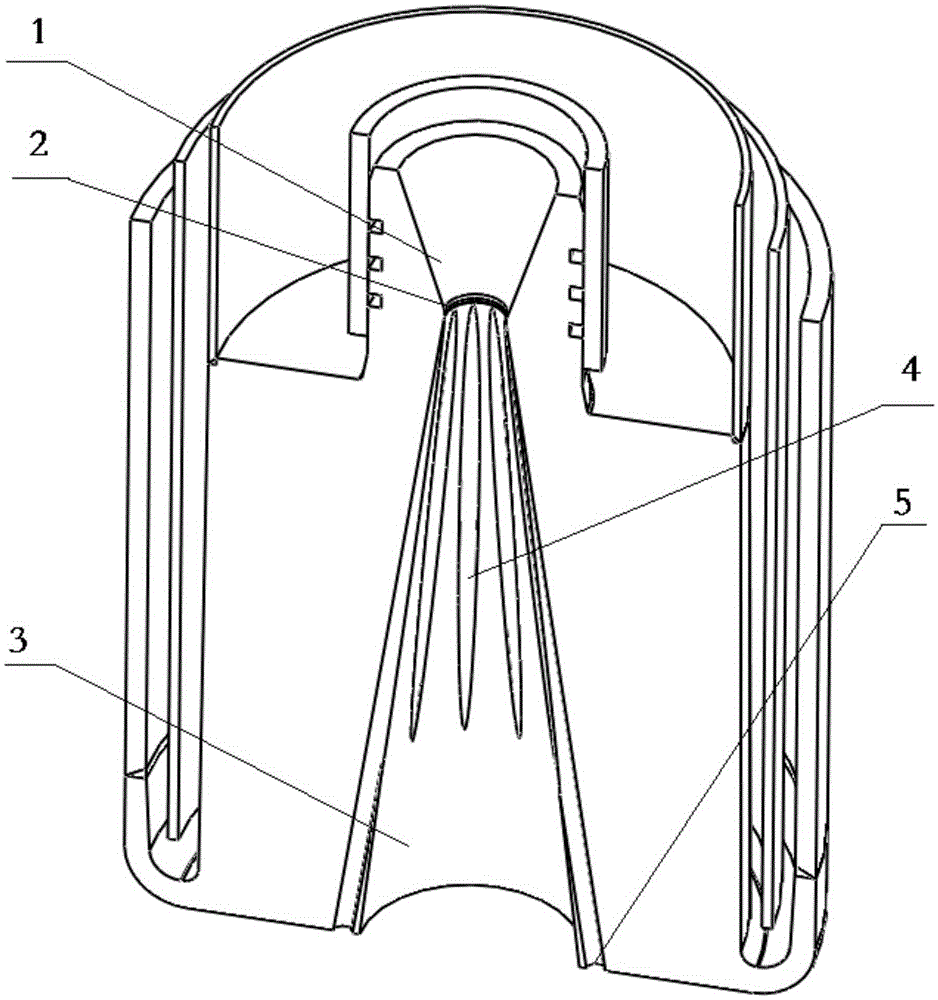

[0035] Such as Figure 1 to Figure 5 As shown, it is an anti-slag entrainment supersonic nozzle applied to the RH top gun. Its main structure is a single-hole Laval nozzle, including the main oxygen channel and the auxiliary oxygen channel. The main oxygen channel is formed by the center of the supersonic Laval tube. Holes are formed, and the auxiliary oxygen channel is a slender orifice on the periphery of the center hole of the supersonic Laval tube; the Laval tube is divided into an inlet contraction section 2, a throat constant velocity section 2, and an outlet expansion section 3 along the airflow direction. ; The inlet contraction section 2 compresses and accelerates the airflow, the throat constant velocity section 2 airflow reaches the speed of sound, and the outlet expansion section 3 accelerates the airflow to supersonic speed. Of course, it also includes structures such as water-cooled outer pipes, water risers, and water-cooled inner pipes. Oxygen with a certain p...

Embodiment 2

[0042] Such as Image 6As shown, a porous anti-slag entrainment supersonic nozzle applied to a converter oxygen lance, its main body is a porous Laval nozzle structure, with a plurality of Laval nozzle holes, each of which is surrounded by a Laval nozzle hole. A plurality of throttle holes are provided, and the Laval-type nozzle holes form a main oxygen channel, and the peripheral oxygen channel is formed by a corresponding throttle hole on the periphery of each main oxygen channel. Multiple Laval nozzles simultaneously inject oxygen into the molten steel bath of the converter. For each Laval nozzle, there is a main oxygen channel and a secondary oxygen channel. The main oxygen channel of the nozzle is the central hole channel of the supersonic Laval tube, and the secondary oxygen channel is the slender orifice on the periphery of the supersonic Laval tube. , in this example, the orifice air inlet 4 is at the entrance of the Laval pipe, and the orifice air outlet 5 is around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com