A method for starting a drain valve and a starting mechanism using the method

A start-up mechanism and drain valve technology, which is applied to flushing equipment with water tanks, water supply devices, buildings, etc., can solve problems such as bad hand feeling, large operating force, and affecting user experience, so as to achieve good operating feel and low operating force , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

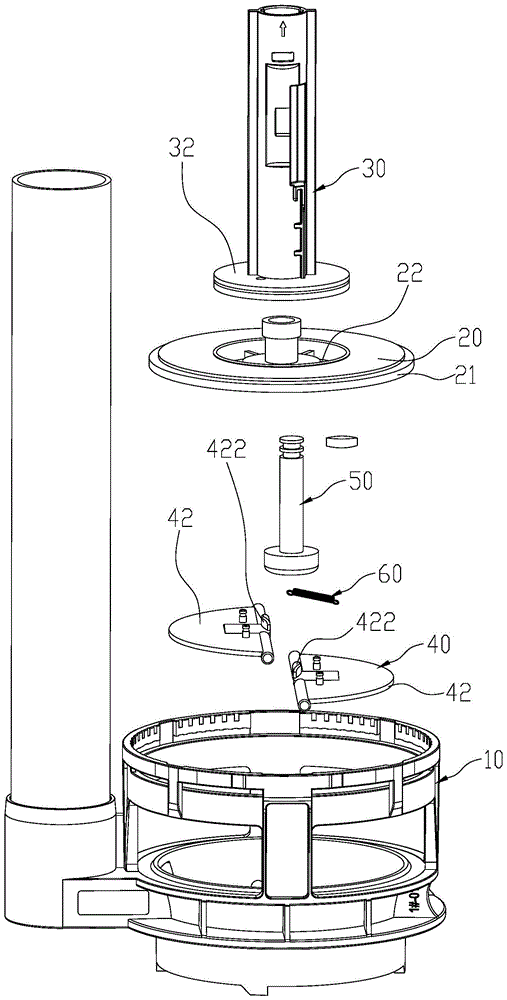

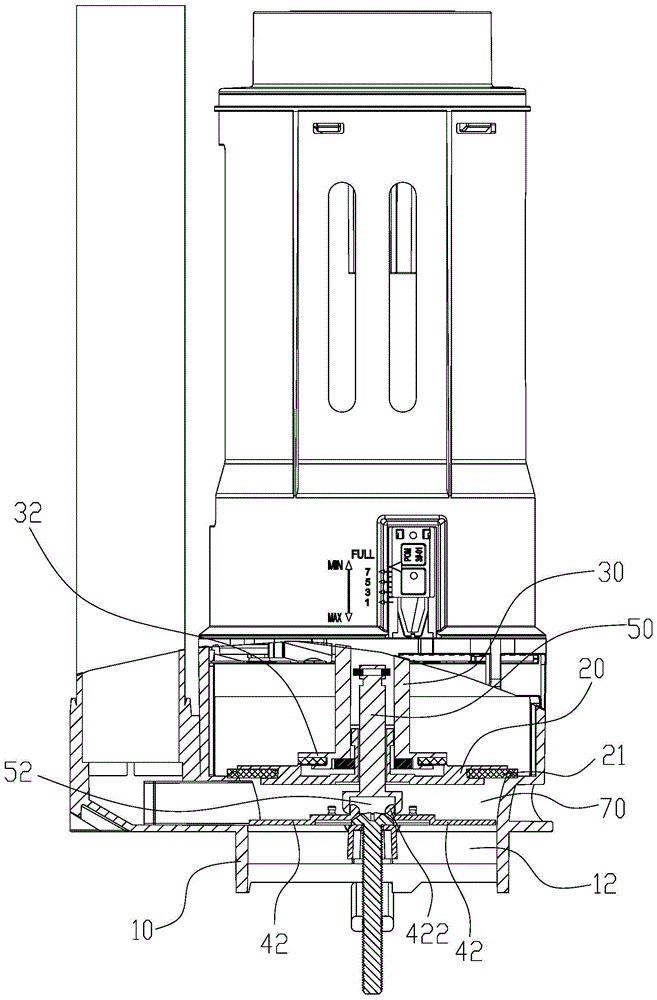

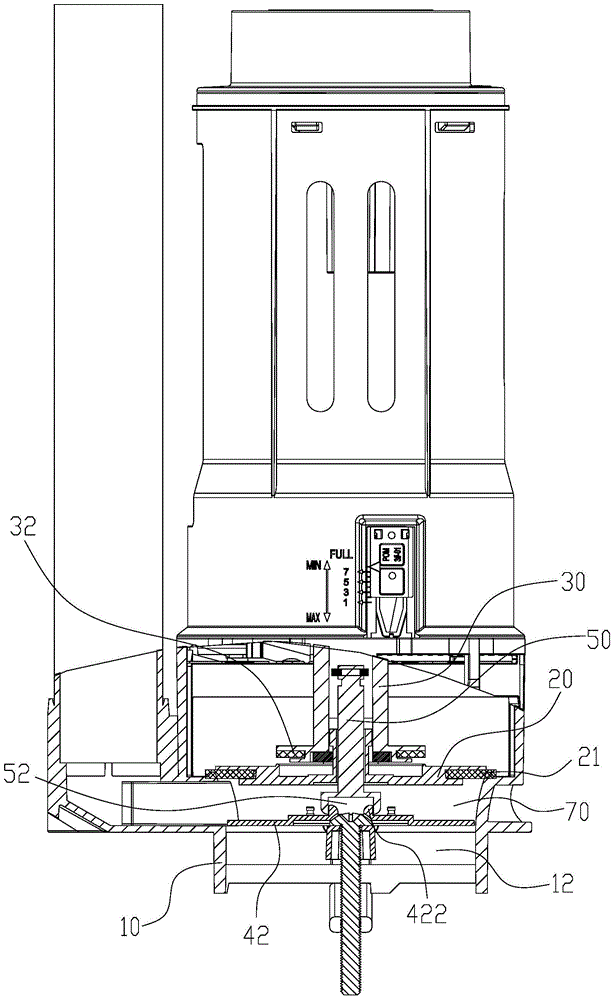

[0034] Please refer to figure 1 and figure 2 , a drainage valve activation mechanism of the present invention, including a base 10 , a water stop plate 20 , an activation rod 30 , a water retaining plate 40 , a control member 50 , and an elastic member 60 .

[0035] The base 10 is provided with a drainage channel 12 . The water stop plate 20 is used to cover the top opening of the drain channel 12, and a water stop rubber pad 21 is fixed on the water stop plate 20, which is used to seal the drain channel 12 when the drain valve is closed, preventing water from entering the drain channel. Inside channel 12. A through hole 22 is formed vertically in the middle of the water stop plate 20 . The activation rod 30 can vertically reciprocate and is used to open the water stop plate 20 . An end cap 32 for covering the through hole 22 extends outwardly from the bottom of the activation rod 30 .

[0036] The water deflector 40 is disposed in the drainage channel 12 . The water ba...

Embodiment 2

[0043] Please refer to Image 6 and Figure 7 The difference between the second embodiment and the first embodiment is that: the bottom of the outer edge of the leaf 42a is pivotally connected with the base 10, and the middle of the inner edge of the leaf 42a is provided with a socket 424; the bottom surface of the control member 50a An insertion rod 54 is provided on the top, and the insertion rod 54 is inserted into the two insertion holes 424 when the water shield is in a closed state, so as to prevent the two leaf pieces 42a from turning downwards and opening.

[0044] When the control member 50a moves upward and the plunger 54 is pulled out from the insertion hole 424, the water pressure acts on the leaf 42a to open the leaf 42a. The elastic member can be connected between the base 10 and the leaf 42a, so that the leaf 42a can automatically reset to a horizontally closed state after being opened.

Embodiment 3

[0046] Please refer to Figure 8 The difference between Embodiment 3 and Embodiment 1 is that: the water retaining plate 40b is vertically reciprocated and arranged in the drainage channel 12, the water retaining plate 40b is connected to the bottom end of the control member 50b, and the water retaining plate 40b and the control member 50b are integrally formed. When the control member 50b moves up and out of the drainage channel 12 , the water can be quickly discharged from the drainage channel 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com