Method for eliminating suction between tower bottom plate and foundation in tower replacement construction

A tower bottom plate and construction technology, applied in the field of tower replacement construction, can solve the problems of inconvenience, crane cost and labor cost, and achieve the effects of saving rental costs, reducing tower dismantling time, and reducing engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

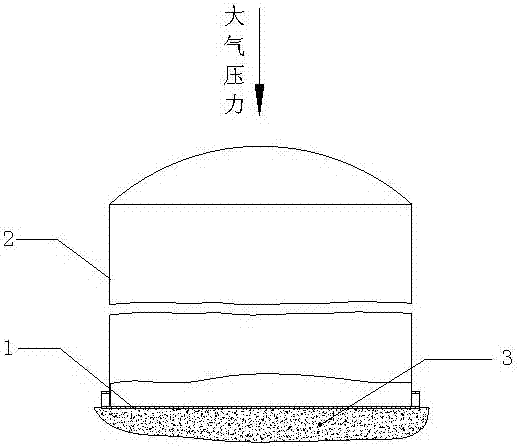

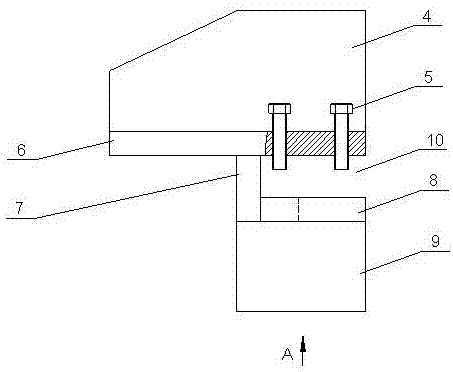

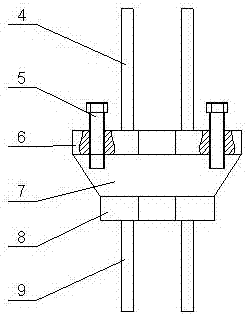

[0037] The method for eliminating suction between the tower bottom plate and the foundation in the tower replacement construction of the present invention comprises the following steps:

[0038] see now Figure 2-5 , figure 2 It is the front view of the prefabricated device for eliminating the suction between the bottom plate of the tower and the foundation according to the embodiment of the present invention, image 3 It is the right side view of the suction device for eliminating the suction between the bottom plate and the foundation of the prefabricated tower according to the embodiment of the present invention, Figure 4 It is the left side view of the prefabricated device for eliminating suction between the bottom plate of the tower and the foundation according to the embodiment of the present invention, Figure 5 for figure 2 A-direction view in .

[0039] a. Prefabricated suction device to eliminate the suction between the tower bottom plate and the foundation

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com