Ink mixing and filtering device of printing machine

A filter device and printing press technology, applied in printing presses, rotary printing presses, gravure rotary printing presses, etc., can solve the problems of waste, inability to separate, etc., and achieve the effects of improving quality, saving materials, and having a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

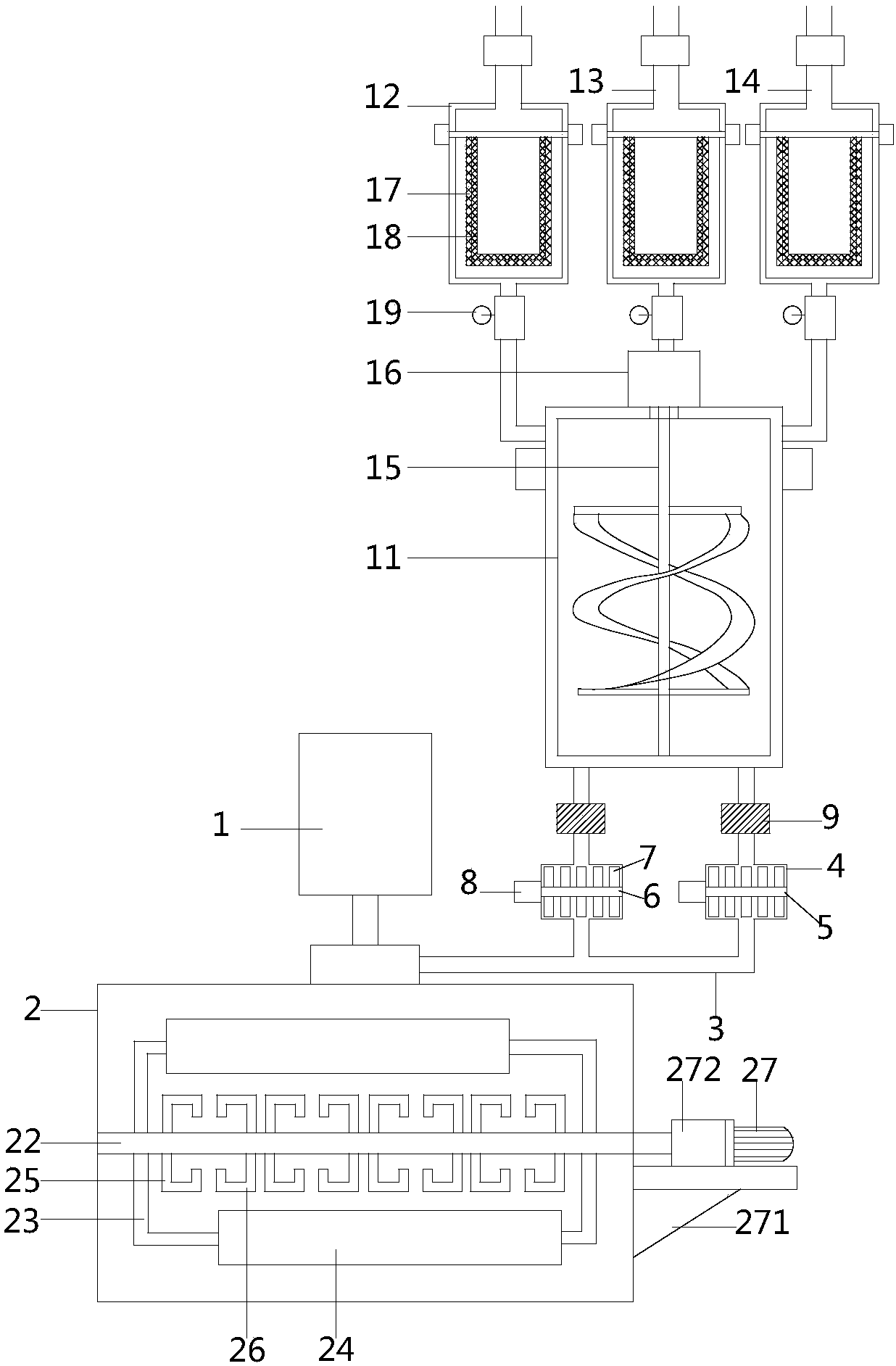

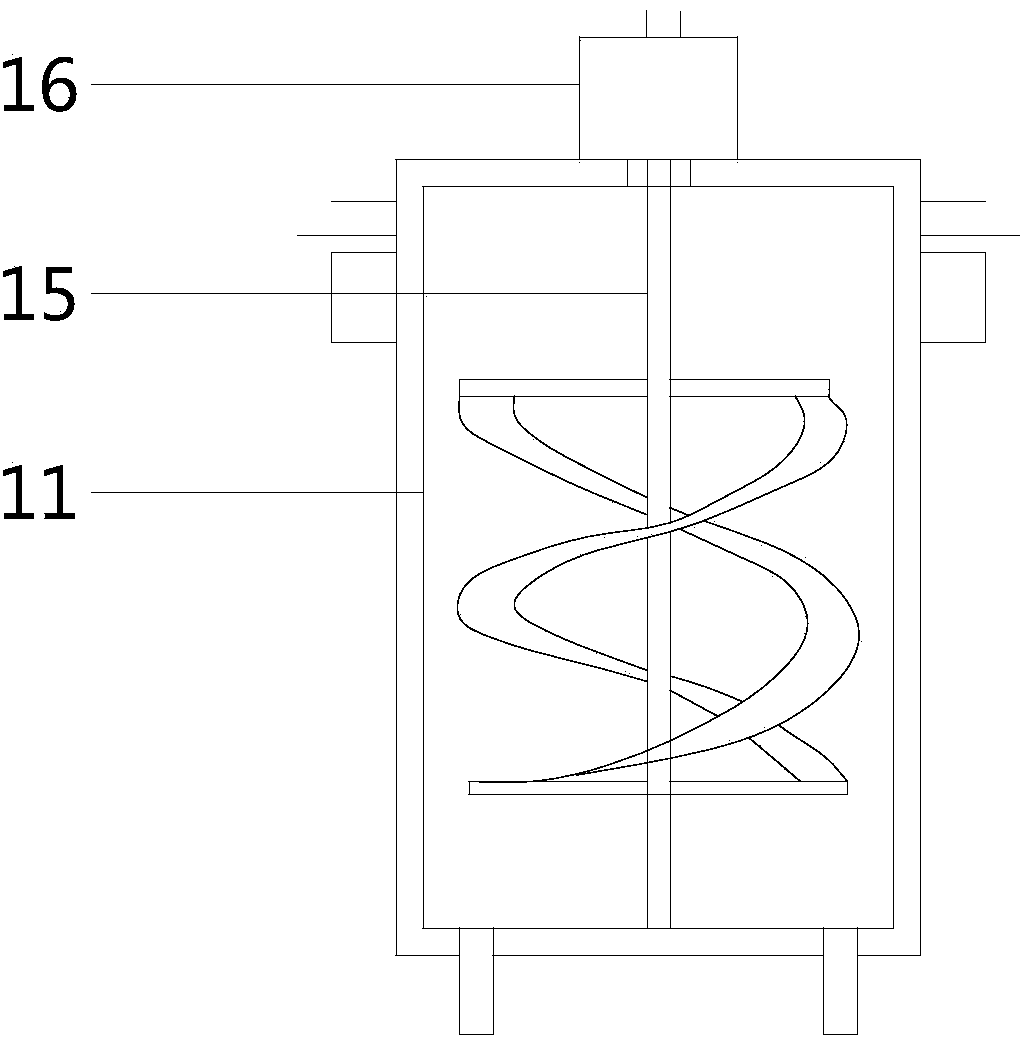

[0016] Attached below Figure 1-3 An embodiment of the present invention is described.

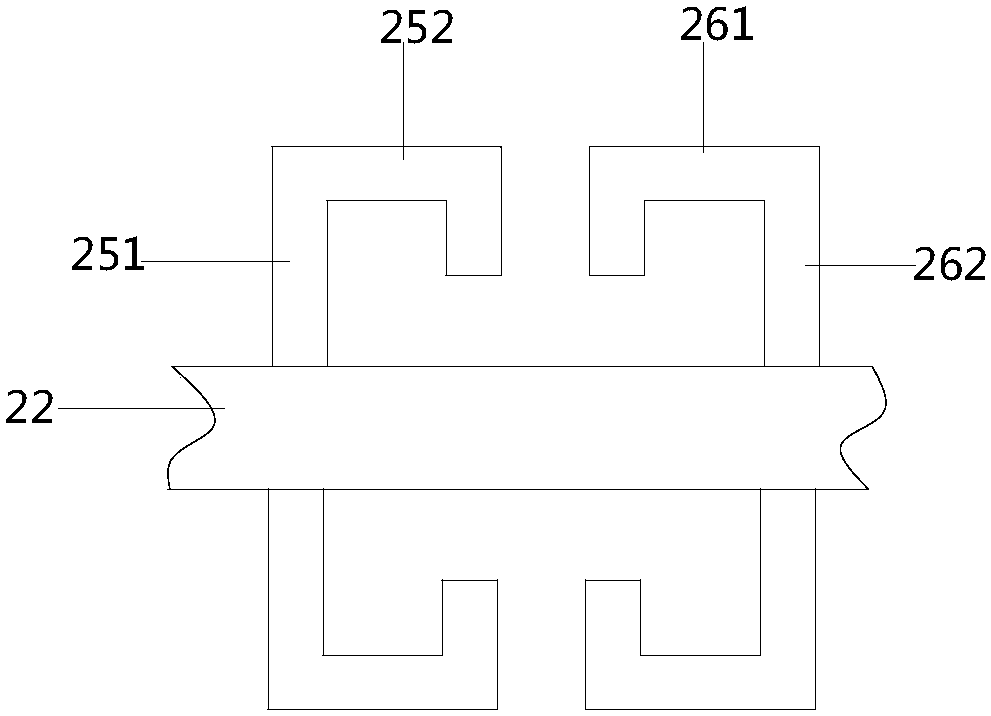

[0017] An ink mixing and filtering device for a printing machine, comprising an ink pump 1, an ink tank 2, an iron removal mechanism 5 and a mixing mechanism, the ink pump 1 is arranged on the top of the ink tank 2, and the ink pump 1 is connected to a liquid inlet Pipe 3 and liquid inlet pipe 3 are respectively connected to two iron removal chambers 4 through two liquid inlet branch pipes. Both iron removal chambers 4 are equipped with iron removal mechanisms 5, and both iron removal mechanisms 5 include horizontally arranged iron removal chambers. The first rotating shaft 6 inside the cavity 4, the magnet sheet 7 arranged symmetrically up and down on the outer wall of the first rotating shaft 6, and the rotating motor 8 driven and connected to the first rotating shaft 6, each of the iron removal chambers 4 is equipped with Five pairs of magnet pieces 7, the upper sides of the two iron r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com