Oxygen-enriched fuel gas supply device and method for fuel gas injector

A gas supply and injector technology, which is applied in the testing of jet propulsion devices, rocket engine devices, gas turbine engines, etc., can solve the problems of difficult testing, difficult control and measurement, and small hydrogen flow, and reduce the difficulty of testing. effect on trial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

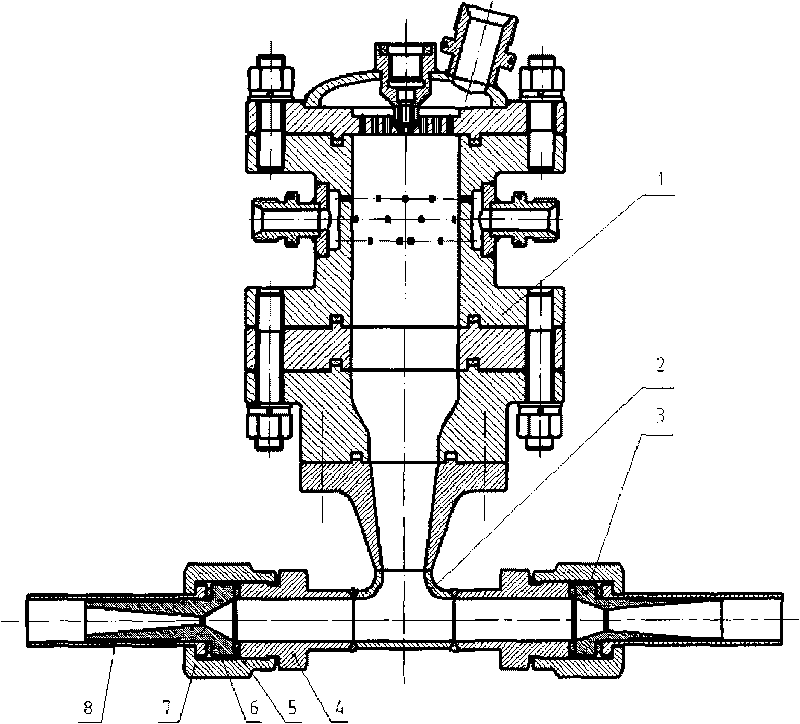

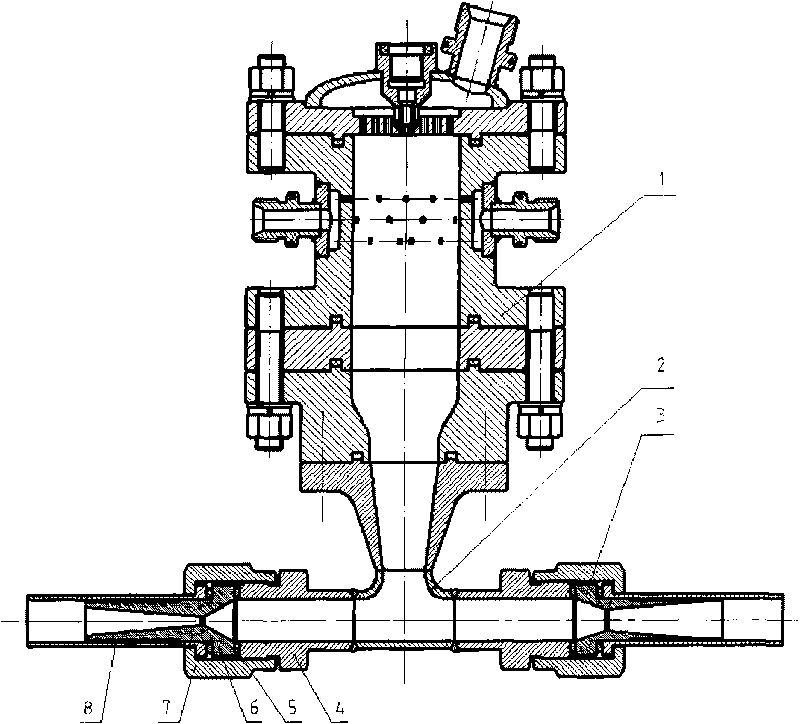

[0009] Further illustrate the present invention below in conjunction with accompanying drawing.

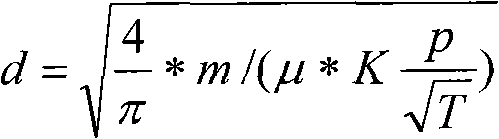

[0010] like figure 1 , the oxygen-enriched gas supply device includes: oxygen-enriched gas pre-combustion chamber 1, tee adapter 2, external sonic nozzle 3, nozzle 4, copper sealing gasket 5, oxygen-enriched gas inlet sonic nozzle 6, nut 7, pipe Connector 8. Oxygen-enriched pre-combustion chamber 1 can be designed under a large hydrogen flow rate, which is easy to control and measure. Through the three-way adapter 2, part of the oxygen-enriched gas passes through the oxygen-enriched gas inlet sonic nozzle 6 and enters the gas injector, and part of it passes through the outer sonic flow rate. The nozzle 3 opens into the atmosphere. The sonic nozzle is installed between the connecting nozzle 4 and the pipe fitting 8, and the pressure acting on the red copper sealing ring 5 by tightening the nut 7 realizes the sealing, and the sonic nozzle is easy to replace.

[0011] The specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com