Full-flow test bed oxygen system

A technology of oxygen system and test system, which can be used in measurement device, engine test, machine/structural component test, etc., and can solve problems such as explosion of oxygen pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

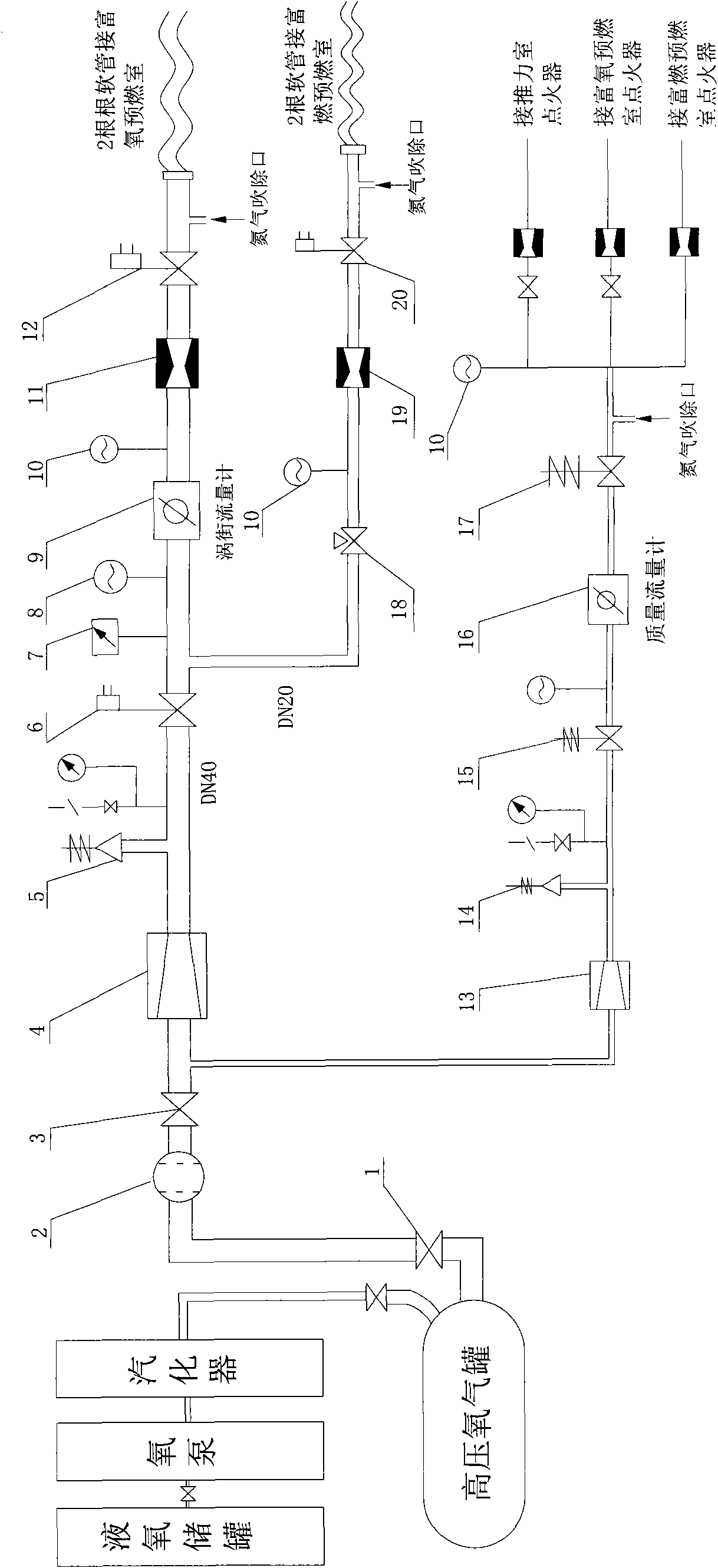

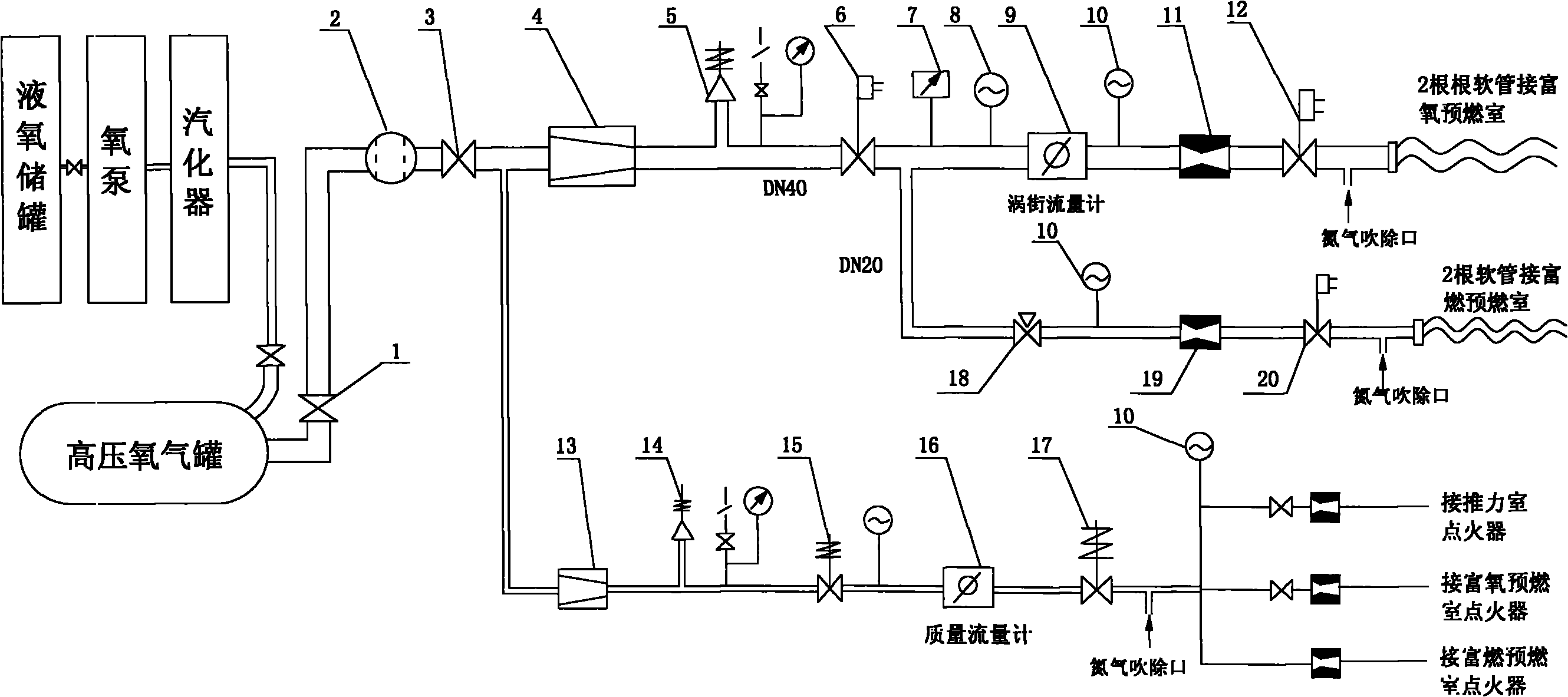

[0008] The present invention proposes the oxygen system design of the full flow test bench for the first time. The supply system can be divided into the main oxygen circuit and the ignition oxygen circuit, which is specifically composed of a liquid oxygen storage tank, a liquid oxygen pump, an evaporation device, a high-pressure oxygen tank, a valve, a pressure reducer and a sonic nozzle; the supply system is designed with pressure and temperature measurement The port is convenient for calculating the flow rate of the medium in the pipeline; the nitrogen purge and replacement interface is designed to purge the residual oxygen in the pipeline.

[0009] The oxygen system uses the method of evaporating liquid oxygen to provide oxygen for the full flow test bench. Fill the liquid oxygen into the liquid oxygen storage tank, pressurize the low pressure liquid oxygen to high pressure through the liquid oxygen pump, and convert the high pressure liquid oxygen into high pressure oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com