Water-jet cutting machine

A technology of waterjet cutting and cutting machine, which is applied in the direction of abrasive jetting machine tools, abrasive materials, metal processing equipment, etc. It can solve the problems of lengthening, affecting the accuracy of machined workpieces, and increasing the swing range of the nozzle along the support point, etc., to achieve the swing range small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

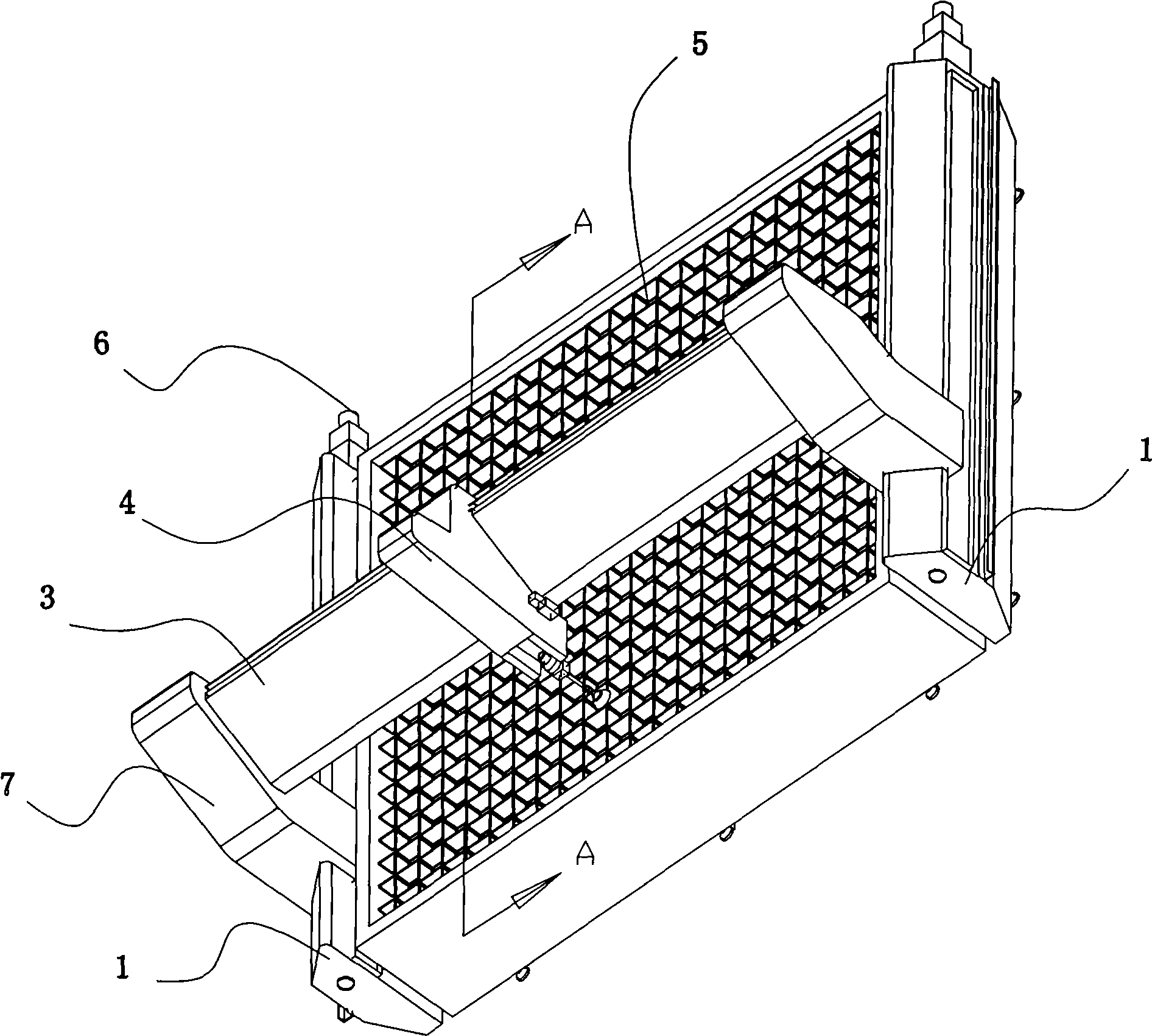

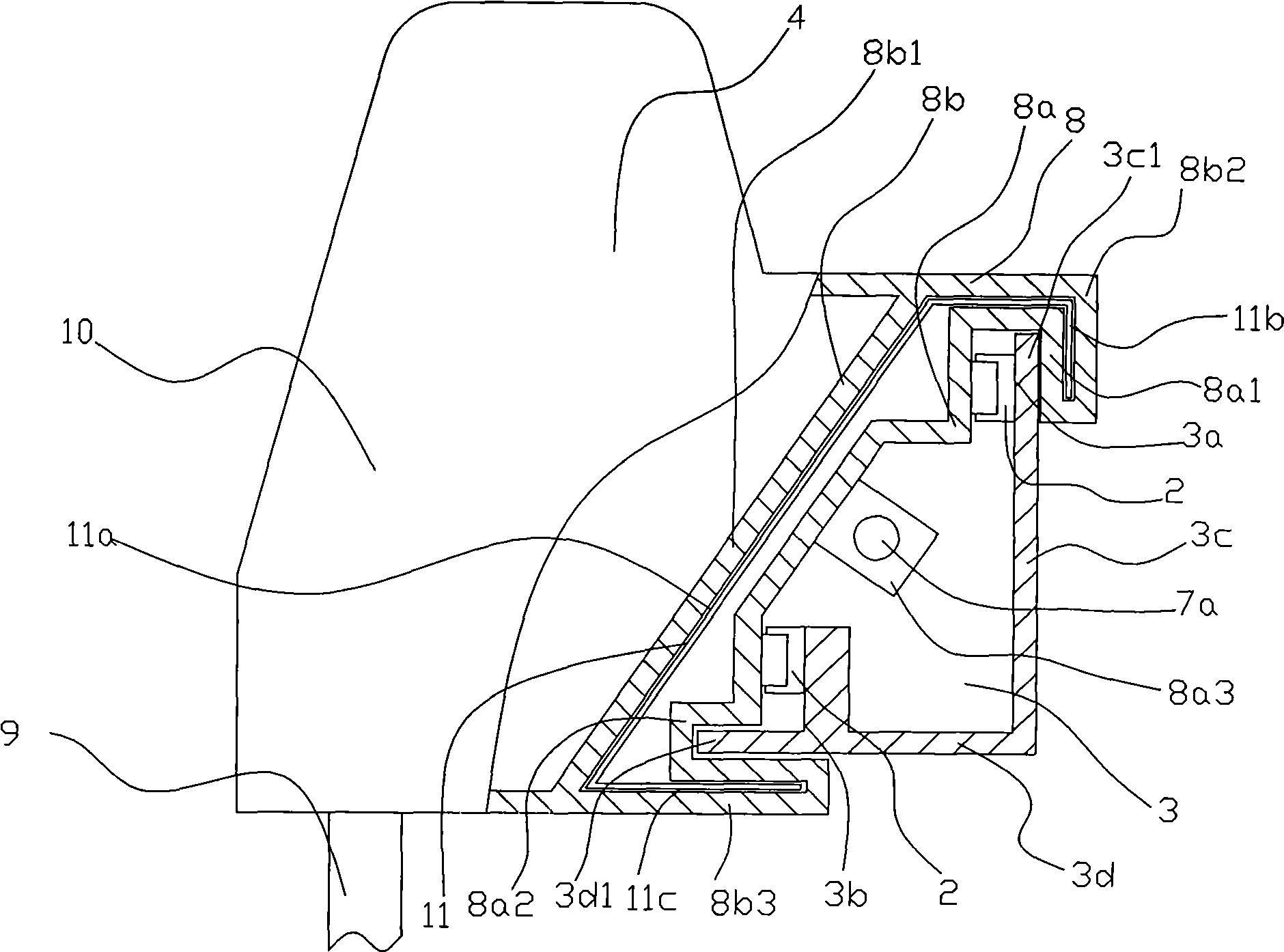

[0009] As shown in the figure, the present invention includes a front and rear mobile frame 1 with a vertical guide rail (ball guide rail), a left and right mobile frame 3 with a horizontal guide rail (ball guide rail) 2 connected to the vertical guide rail, and a left and right mobile device The water jet cutting head 4 on the transverse guide rail 2, the workpiece carrying platform 5 arranged under the water jet cutting head 4, the longitudinal power mechanism 6 that drives the left and right moving frame 3 to move back and forth, and the transverse direction that drives the water jet cutting head 4 to move left and right Power mechanism 7, the transverse guide rail 2 that is arranged on the left and right mobile frame 3 has two covers, is respectively arranged on the upper end 3a of the left and right mobile frame 3 and the front end 3b below, the back s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com