Punching device for aluminum foil or copper foil of lithium battery and production technology

A technology for punching equipment and lithium batteries, which is applied in battery electrodes, circuits, electrode manufacturing, etc. It can solve problems such as difficult to meet the requirements of use, large burr size, and irregular hole distribution, so as to achieve regular punching distribution and improve battery life. , Provide the effect of battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with each specific embodiment and accompanying drawing, the present invention will be further described:

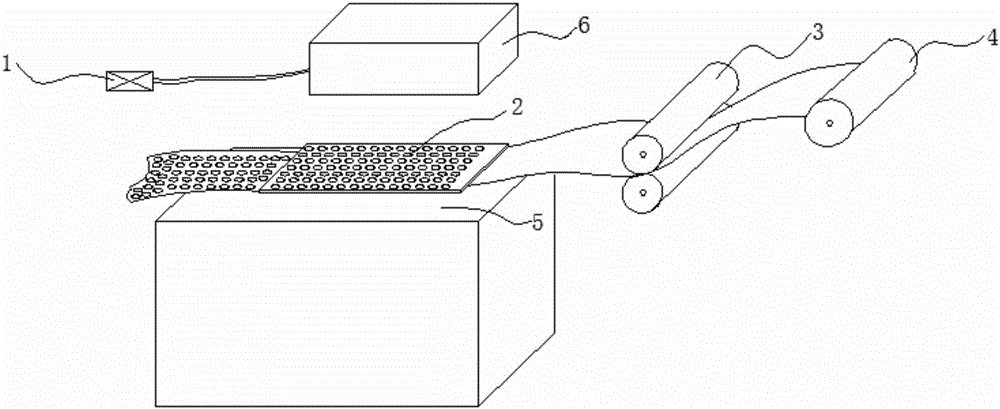

[0022] Such as figure 1 As shown, the punching equipment for aluminum foil and copper foil of a lithium battery, the punching equipment includes a frame, a pressurized water pump 1, a water knife 6, a porous cutting upper die 2, and a feed roller 4, a transmission Roller 3, punching lower die table 5, pressurized water pump 1 pressurizes water into water knife 6, feeding roller 4 sends aluminum foil or copper foil to punching lower die table 5 through conveying roller 3, conveying roller 3 It can be driven by a motor to rotate, and the high-pressure water of the water jet 6 passes through the holes of the cutting upper die 2 and is sent to the punching lower die workbench 5 to punch holes in the foil or copper foil. small

[0023] The equalizing water pump 1 pressurizes the water to 100-400MPa, and the high-pressure water jet quickly enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com