Wet etching method and device for solar cells

A technology of solar cells and wet etching, which is applied in the field of solar cells, can solve the problems of increasing the production cost and high processing cost of solar cells, and achieve better cleaning effect, reduce water volume, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

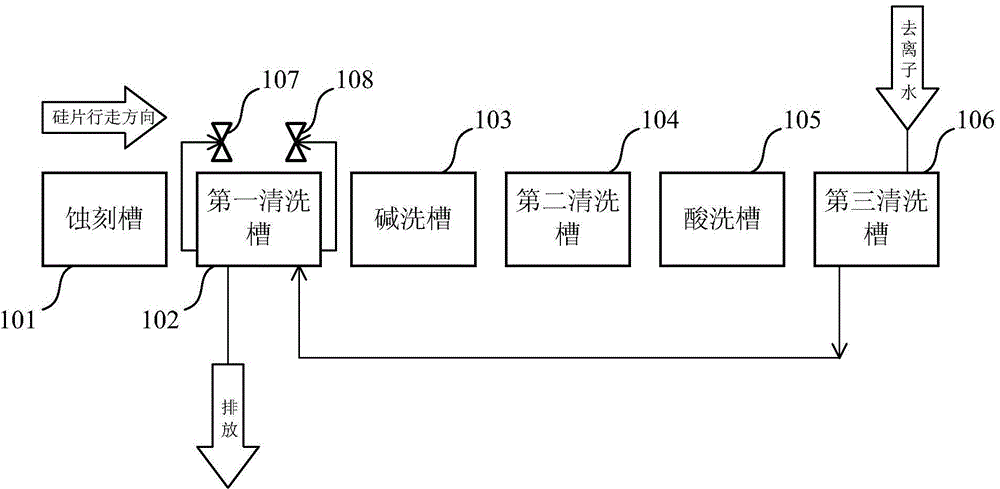

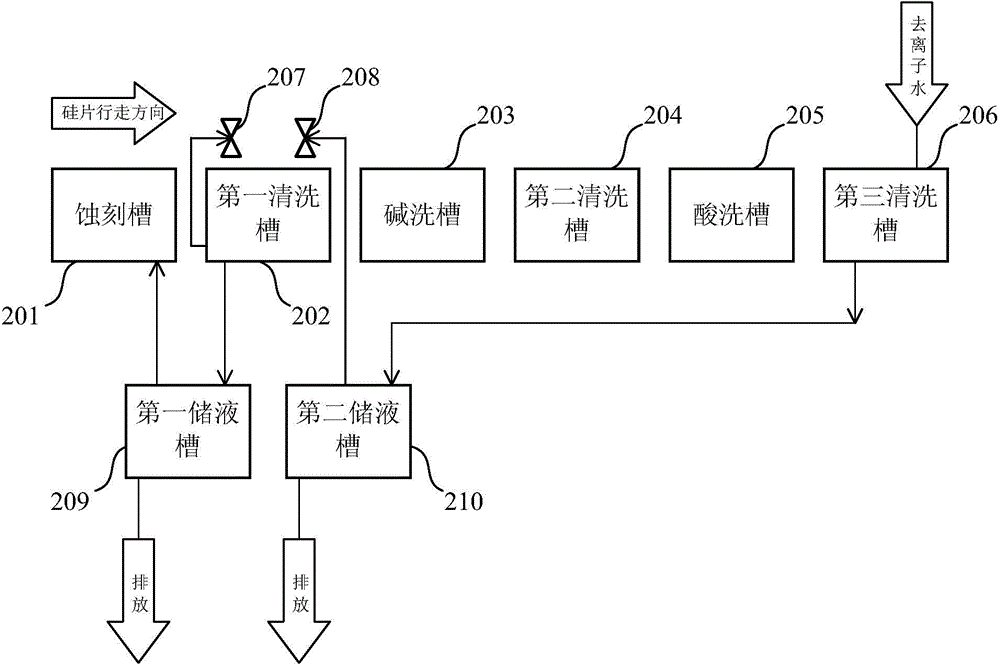

[0042] The invention provides a wet etching device for solar cells, please refer to figure 2 , is shown as a structural schematic diagram of the device, including an etching tank 201, a first cleaning tank 202, an alkali cleaning tank 203, a second cleaning tank 204, an acid cleaning tank 205 and a third cleaning tank 206 placed in sequence; A first water jet 207 and a second water jet 208 are respectively installed at the entrance and exit of the tank 202; wherein:

[0043] The wet etching device further includes a first liquid storage tank 209 and a second liquid storage tank 210 .

[0044]Specifically, the second liquid storage tank 210 is respectively connected to the third cleaning tank 206 and the second water knife 208 through connecting pipes, and when the liquid in the third cleaning tank 206 reaches a preset water level, Drain excess liquid to the second liquid storage tank 210, and the second liquid storage tank 210 supplies liquid to the second water knife 208; ...

Embodiment 2

[0054] The present invention also provides a kind of wet etching method of solar battery sheet, comprises the following steps:

[0055] Firstly, a solar battery is provided. In this embodiment, the solar battery is taken as an example of a silicon wafer.

[0056] Then, the solar cells are sequentially passed through the etching tank 201, the first cleaning tank 202, the alkali cleaning tank 203, the second cleaning tank 204, the pickling tank 205 and the third cleaning tank 206 through the conveying device;

[0057] in:

[0058] The entrance and exit of the first cleaning tank 202 are respectively equipped with a first water knife 207 and a second water knife 208; when the solar cells reach the first cleaning tank 202, the first water knife and the second water jet spray-clean the front and back of the solar cell sheet respectively;

[0059] The third cleaning tank 206 is connected to the second liquid storage tank 210 through a connecting pipeline, and the deionized water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com