Water cutter device for cutting sapphires

A sapphire and waterjet technology, applied in the field of processing, can solve problems such as material cracks, laser difficulties, and ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

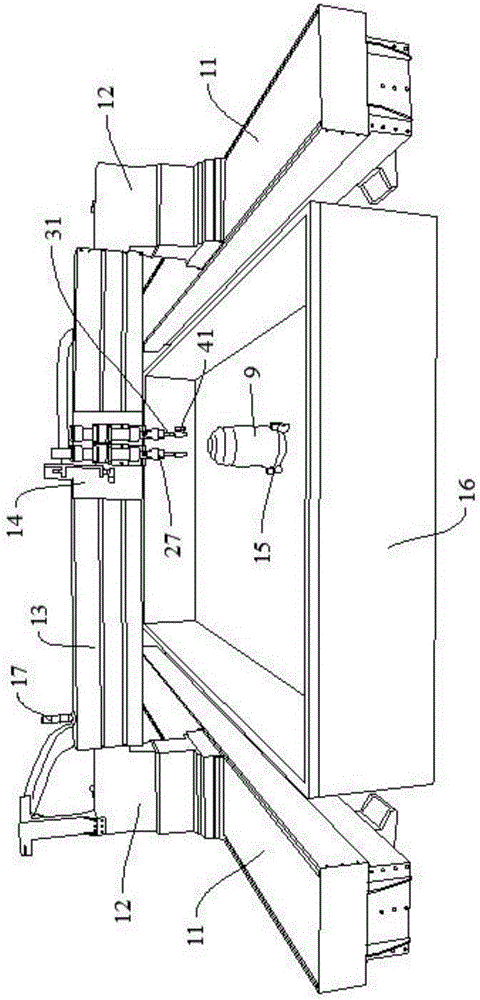

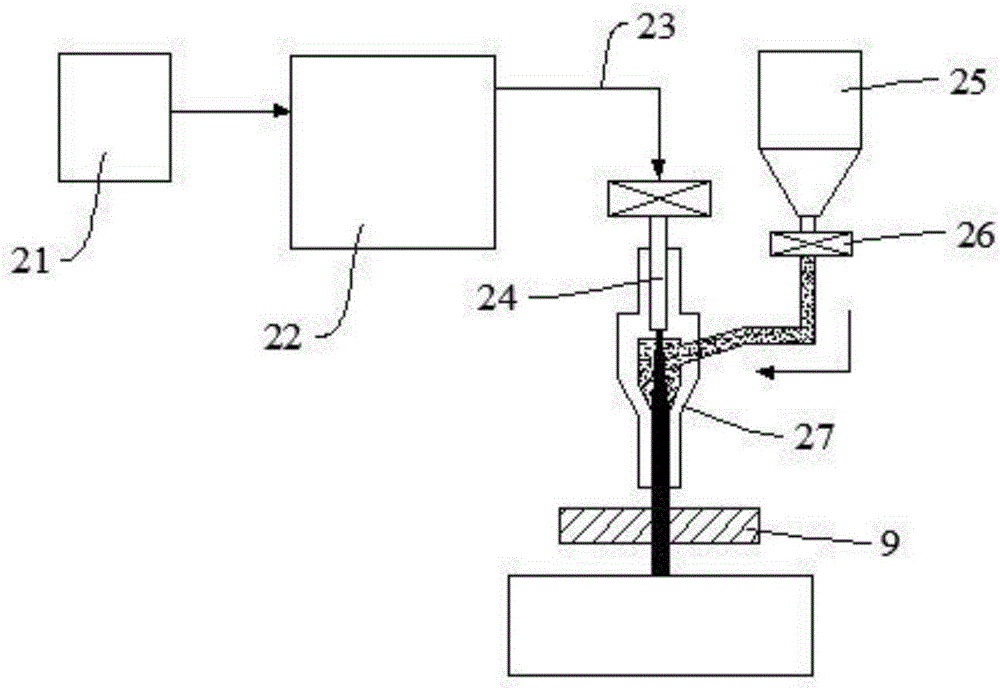

[0025] as attached figure 1 , 2 As shown, a waterjet device for cutting sapphire includes: waterjet machine tool, computer control system, abrasive water jet system, acid spray system, and laser positioning device; wherein, the computer control system is used to control the various parts of the waterjet machine tool The computer control system is also used to control the opening and closing of the abrasive water jet system, the opening and closing of the acid spray system and the jet pressure of the abrasive water jet system; the abrasive water jet system is used to spray ultra-high pressure abrasive water jet to The sapphire workpiece 9 is cut; the acid spray system is used to apply the acid solution at the incision, so that the acid solution is bombarded by the ultra-high pressure abrasive water jet and then impacts the sapphire workpiece 9 at high speed for coordinated chemical processing; the laser positioning device is used for the sapphire workpiece 9 Cutting points pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com