Device capable of quickly cutting aerostat capsule material

A rapid cutting and aerostat technology, which is applied in metal processing and other directions, can solve the problems of cutting material damage, etc., and achieve the effects of easy operation, improved cutting accuracy, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

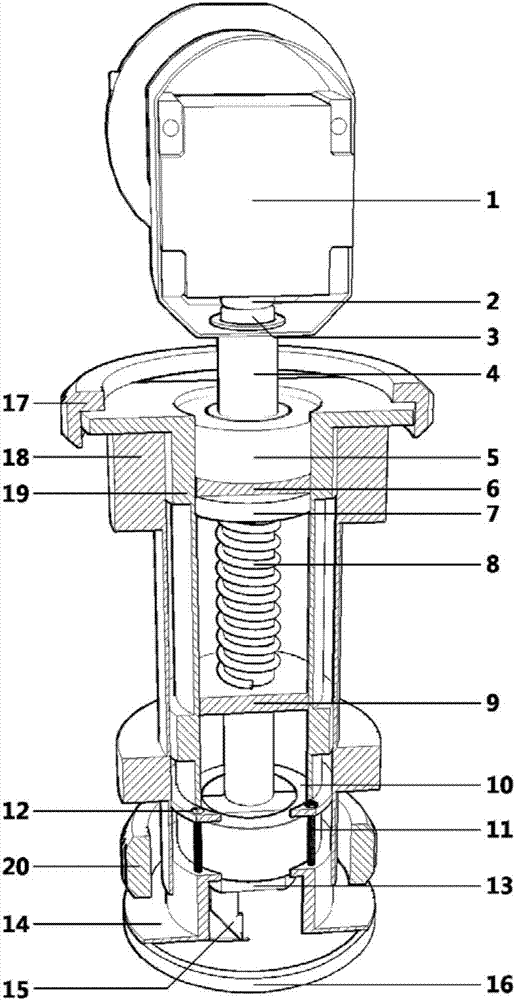

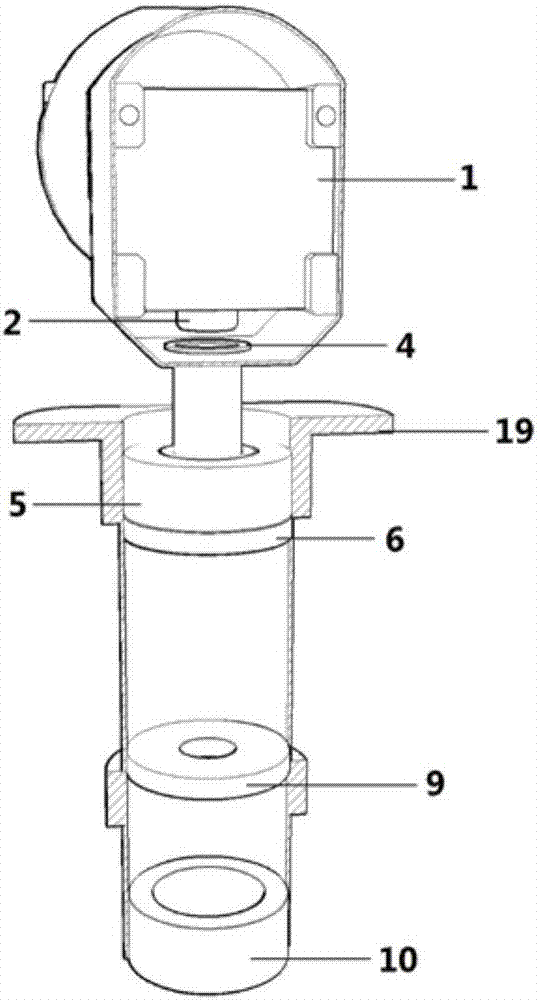

[0026] see figure 1 , a device for quickly cutting aerostat capsule material, is that a combined vibrating tool is set between the vibrating motor 1 and the progressive motor 23 of the CNC cutting equipment, including a transmission rod 3, a bearing 5, a fixed sleeve 10, and a protective shell 18 and protection inner shell 19.

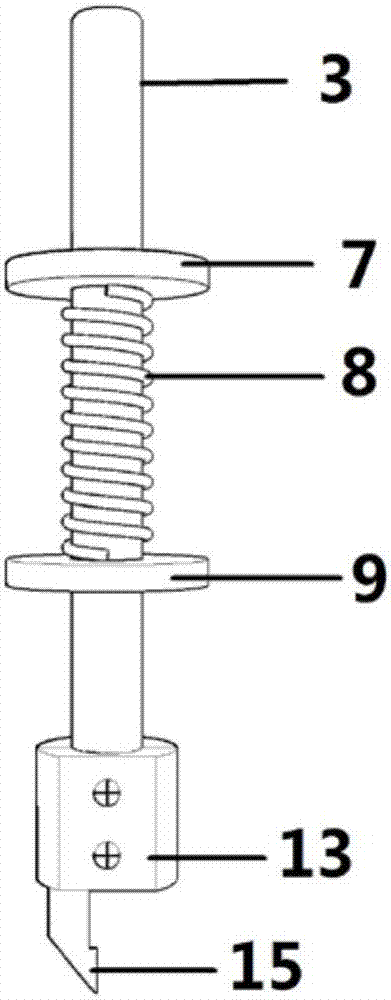

[0027] see figure 1 with figure 2 , the transmission rod 3 is a cylindrical rod vertically arranged, the lower end of the transmission rod 3 is provided with a blade clamp block 13 and a tungsten steel blade 15, and the tungsten steel blade 15 is fixed on the lower end of the transmission rod 3 by the blade clamp block 13 At the end, the outer circle of the blade clamping block 13 passes through the inner hole of the fixing sleeve 10 and is in clearance fit with the inner hole of the fixing sleeve 10 .

[0028] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com