Tunneling method of shield equipment in high-viscosity mudstone

A high-viscosity, shield technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as easy sticking of mud cake on the cutterhead, low work efficiency, and blockage of the muddy water warehouse door, so as to avoid manual cleaning when opening the warehouse , Shorten the construction time and delay the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

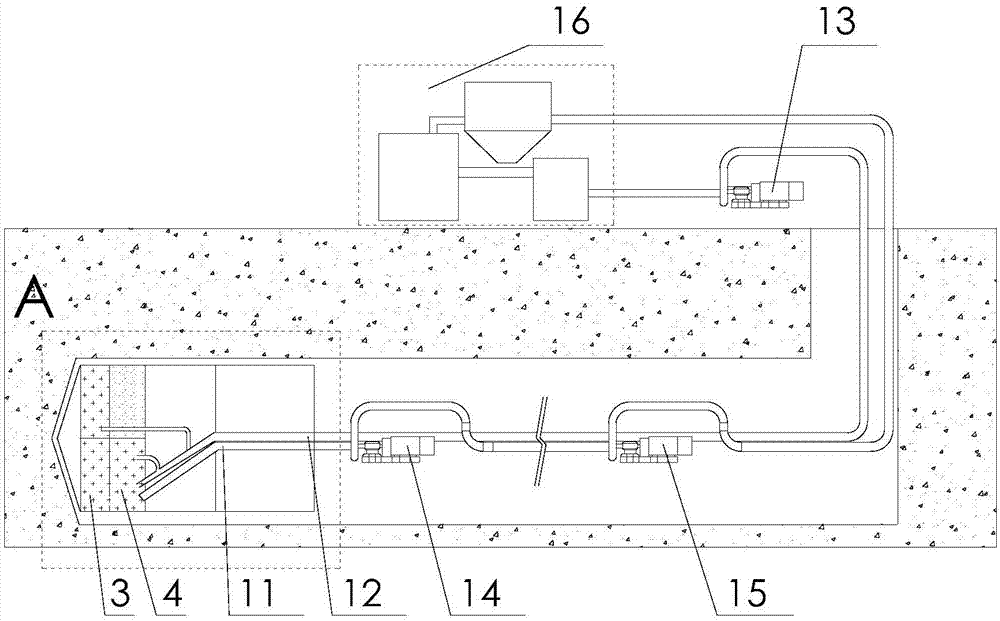

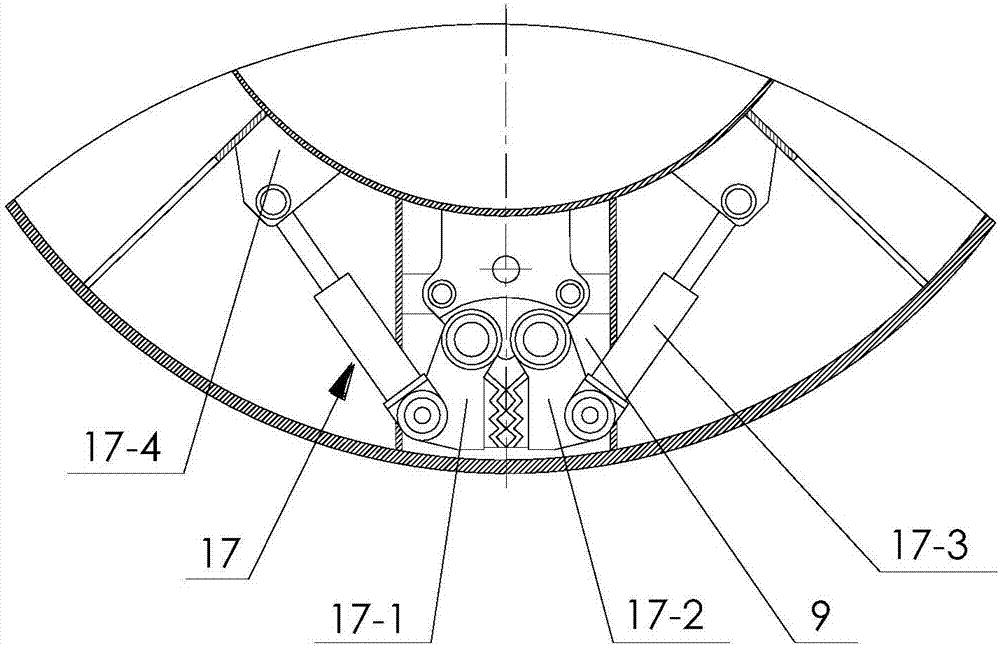

[0054] like figure 1 , figure 2 and Figure 5 As shown, the tunneling method of the shield equipment of the present invention in high-viscosity mudstone comprises the following steps:

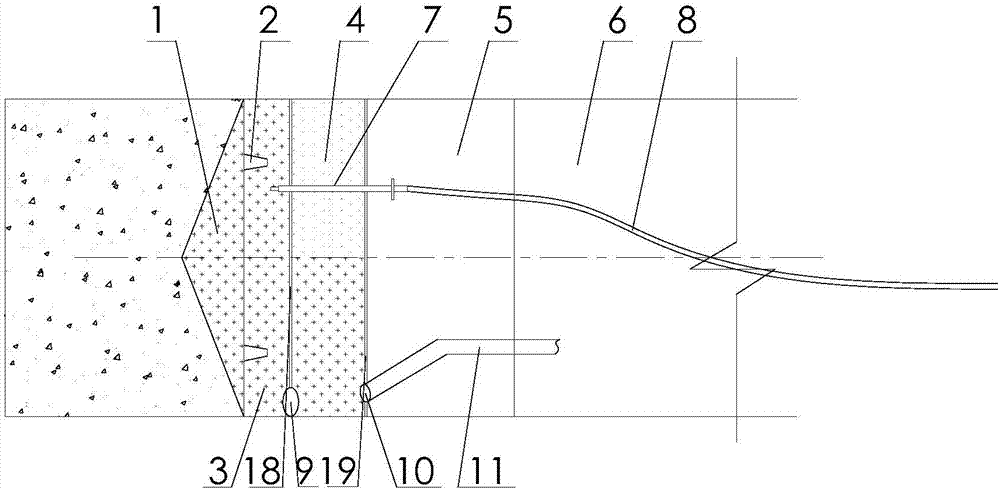

[0055] Step 1. Install the water jet device and check that the flushing pipeline is unblocked: First, install the water jet device 7 and extend it through the air cushion chamber 4 to the muddy water chamber 3, and connect the water jet device 7 with the water pipe through the high-pressure hose 8 and install it on the Connect the water outlet of the high-pressure pump on the supporting trolley behind the shield machine; then, check the flushing pipeline to ensure that each pipeline is unimpeded, and the flushing pipeline includes the high-pressure hose 8 and the muddy water flushing pipe network connected to the nozzle of the shield machine ;

[0056] The water jet device 7 includes a water jet steel pipe 7-1 that passes through the second partition 19 of the shield machine, the air cushio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com