Automatic cutting machine for potato seed potatoes

A technology of potato and dicing machine, which is applied in rhizome seed cutting machine, seed and rhizome treatment, metal processing, etc. It can solve the problems of low work efficiency, potato seed potato waste, affecting potato yield and quality, etc., so as to improve dicing Efficiency, liberating labor force, and improving the effect of seed potato utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

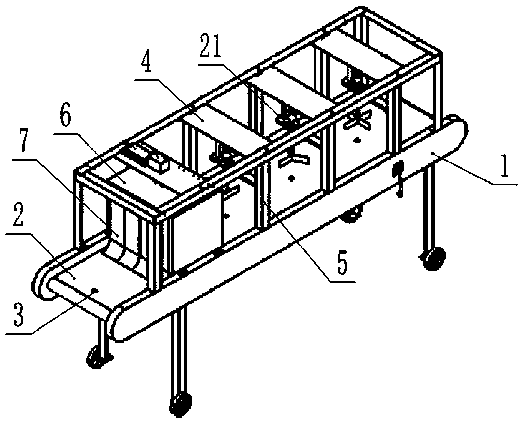

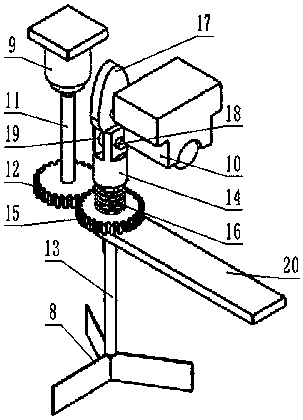

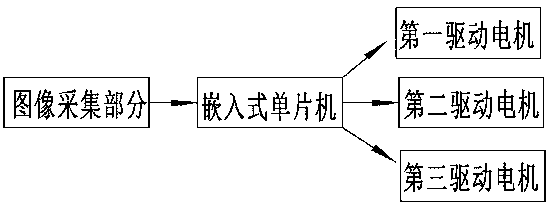

[0025] like figure 1 As shown, the present invention includes a frame 1, a transmission mechanism, a control mechanism, a potato seed identification mechanism and a plurality of groups of cutter mechanisms 21 located above the transmission mechanism and arranged in sequence along the transmission direction.

[0026] The transmission mechanism comprises a driving roller, a passive roller and a conveyor belt 2 connected between the driving roller and the passive roller. A driving motor is connected, and the driving roller is driven to rotate through the first driving motor to provide power for the conveyor belt 2 . In this embodiment, the first driving motor is a 86BYGH86 DC stepping motor.

[0027] On the conveyor belt 2, a plurality of potato seed placement marking points 3 are evenly arranged along its length direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com