Rotary cutting type pipe cutting machine

A rotary cutting and cutting machine technology, used in pipe shearing devices, shearing devices, metal processing machinery parts, etc., can solve the problems of uneven pipe incisions, old-fashioned structures, physical injuries to operators, etc., to achieve smooth incisions and work. High efficiency, no dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

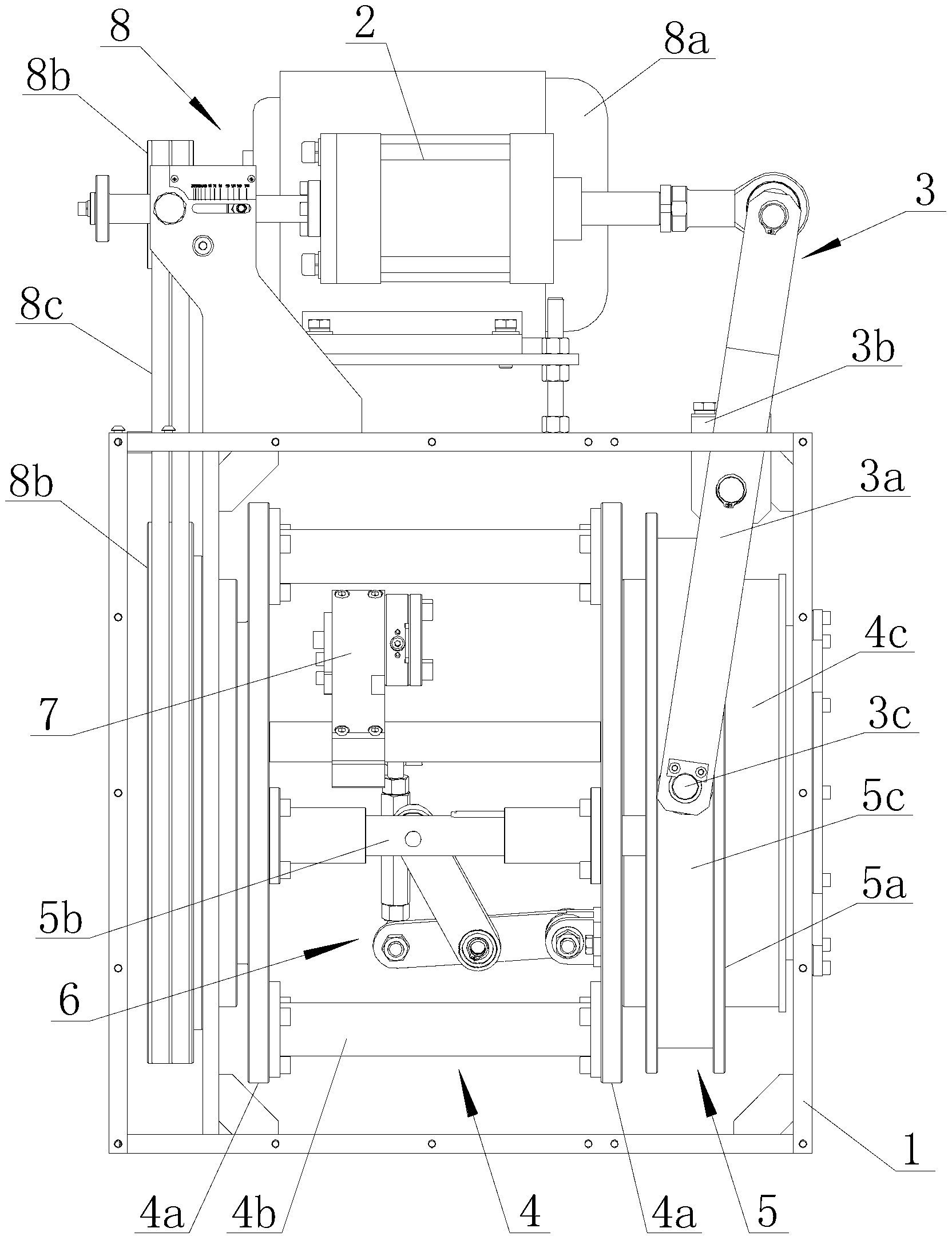

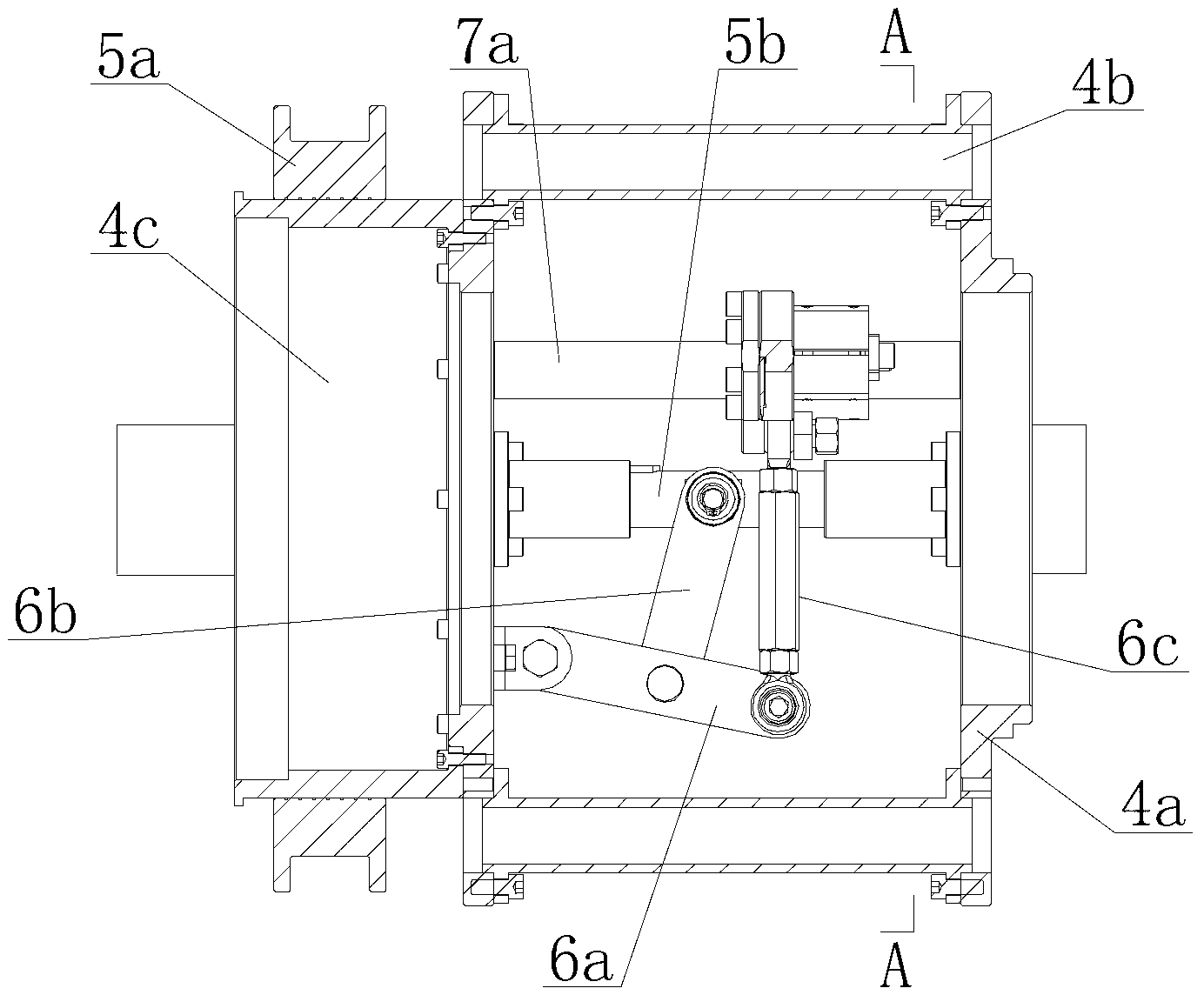

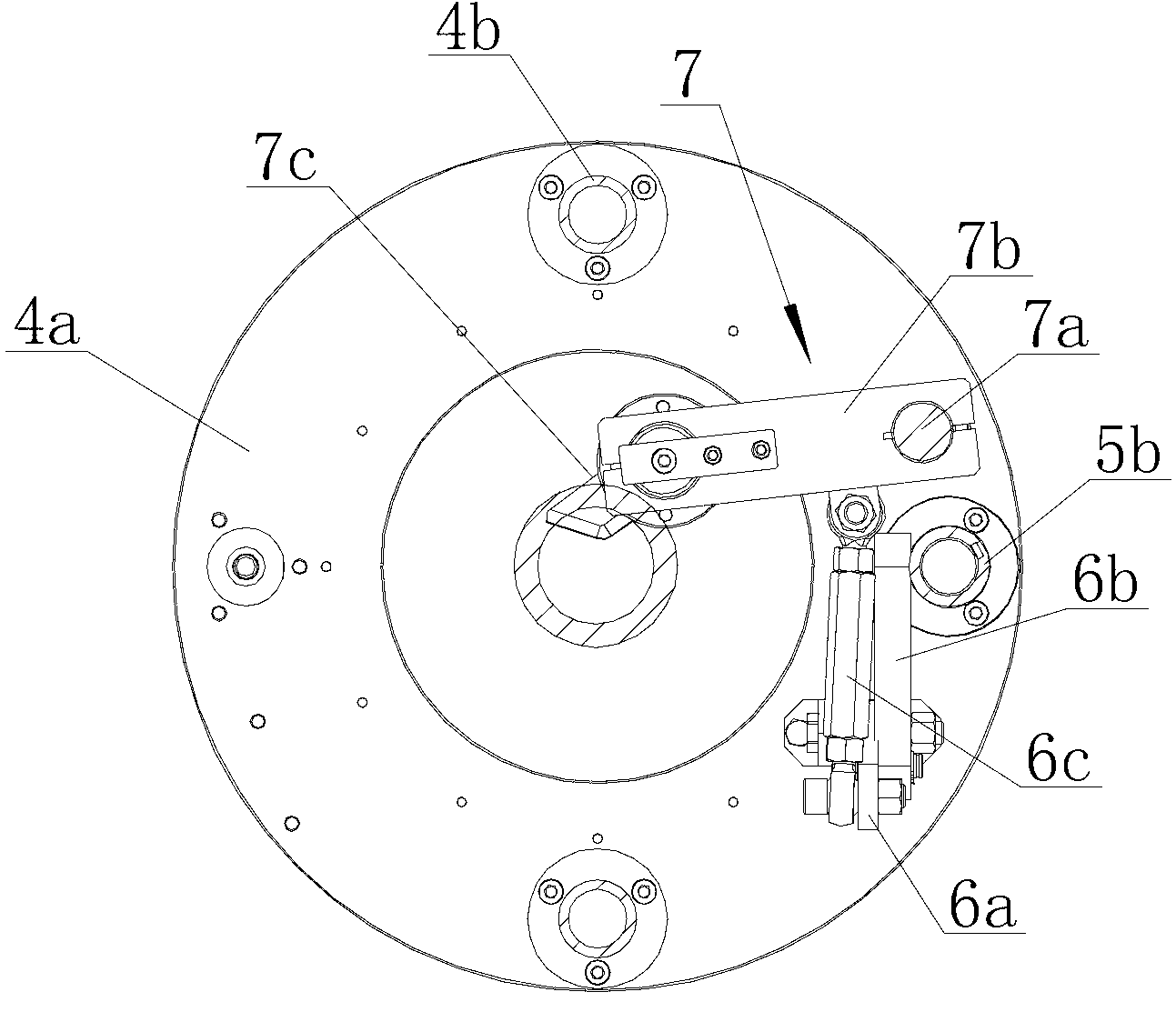

[0020] refer to Figure 1 to Figure 5 As shown, a rotary cutting type pipe cutting machine of the present invention includes a chassis 1, on which a horizontal drive device 2 is provided. The horizontal drive device 2 described in this embodiment is a cylinder, and it can also be used as required. Other drive devices commonly used in the field; a knife advance and retreat mechanism is movably connected in the cabinet 1, and the horizontal drive device 2 is connected to the knife advance and retreat mechanism by a shift fork assembly 3; the knife advance and retreat mechanism is mainly composed of a bracket 4, which is arranged on the The sliding mechanism 5, the connecting rod driving mechanism 6 and the cutting knife assembly 7 are composed; the sliding mechanism 5 is movably connected to the shift fork assembly 3, and the connecting rod driving mechanism 6 is connected with the bracket 4, the sliding mechanism 5 and the cutting knife assembly respectively. The knife assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com