A single-knife plastic pipe rotary cutting device

A rotary cutting, single-knife technology, used in metal processing and other directions, can solve the problem of inability to rotate and cut plastic pipes of different thicknesses, and achieve the effects of enhancing strength, increasing activity space, and reducing occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

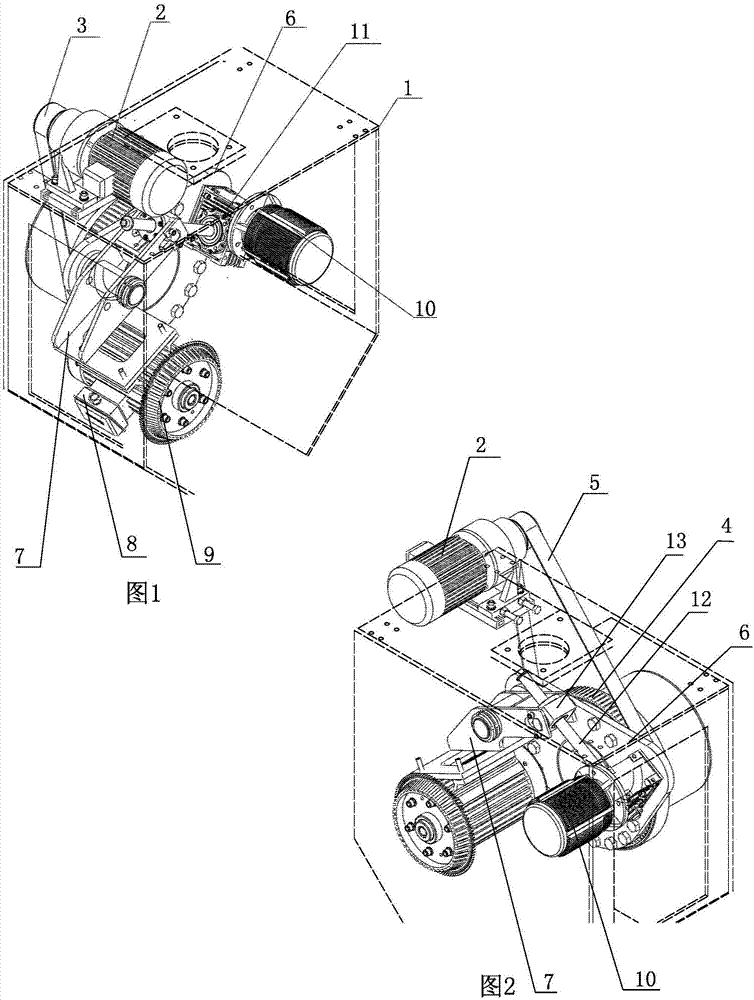

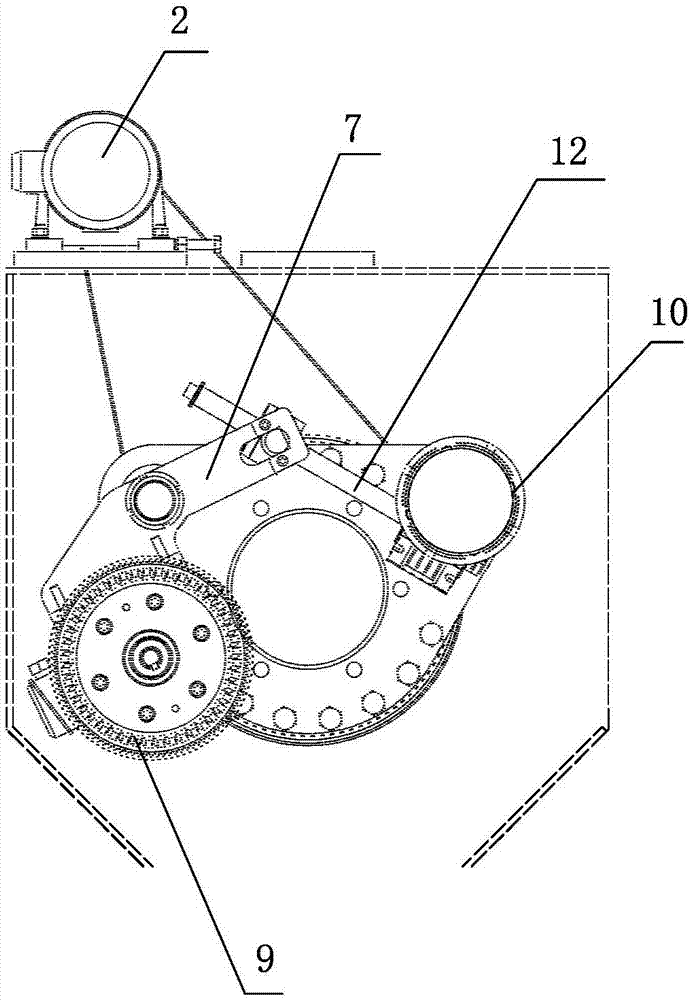

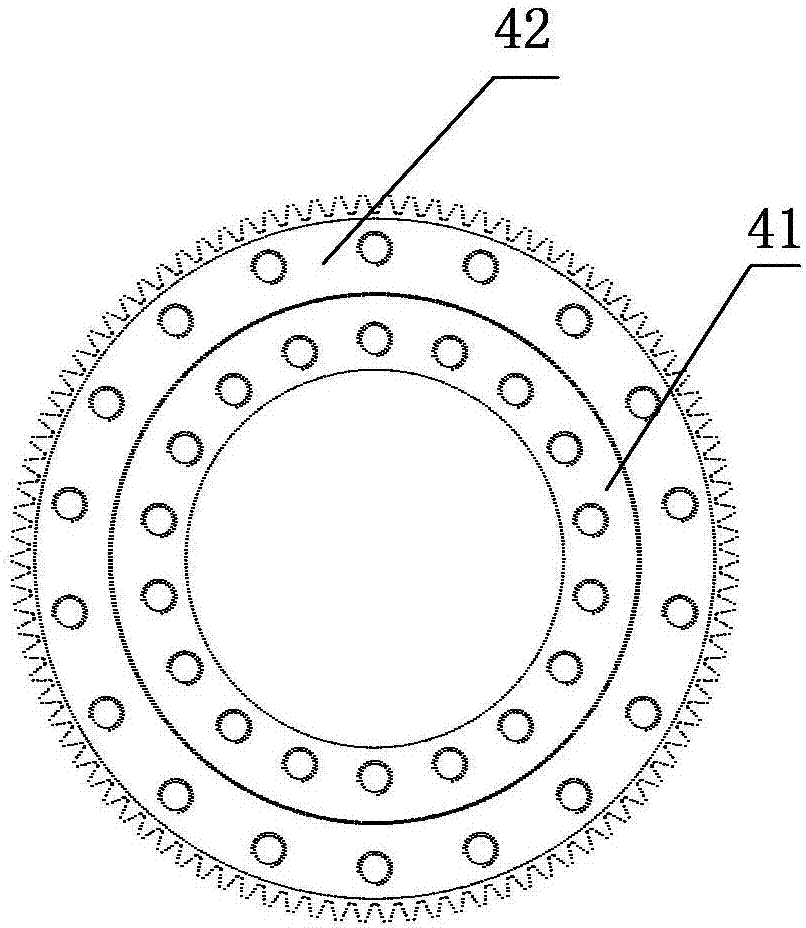

[0025] Such as Figures 1 to 4 As shown, a single-knife plastic pipe rotary cutting device is used to cut plastic pipes so that the plastic pipes meet the size and length requirements. Knife cutting mechanism, swing frame drive mechanism and control system.

[0026] Described cabinet 1 is used for fixing and installing other mechanism components of the present invention, and described cabinet 1 adopts the hollow rectangular structure without front cover, and the rear end cover of described cabinet 1 is provided with discharge opening, and described discharge The feed port is used to pass the cut plastic pipe; the upper end cover of the cabinet 1 is provided with an observation window, and the observation window is used to observe the condition of the mechanism components in the cabinet 1; the cabinet 1 has no front cover, which can facilitate Maintenance of internal components of chassis 1.

[0027] The rotary power drive mechanism is used to drive the rotation of the swing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com