Patents

Literature

38results about How to "Automatic control of telescopic work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly efficient steel pipe surface finishing and polishing device

ActiveCN107052978AImprove grinding efficiencySatisfy the grinding jobPolishing machinesGrinding work supportsEngineeringSteel tube

The invention discloses an environment-friendly efficient steel pipe surface finishing and polishing device. The device comprises a machine frame. The machine frame is composed of a cross beam and supporting feet fixed to the bottoms of the left side and the right side of the cross beam. A sliding groove is formed in the end face of the bottom of the cross beam. A first thread rod extending left and right is arranged in the sliding groove. A sliding block is connected to the interior of the first thread rod in a thread fit mode. A polishing assembly is arranged at the bottom of the sliding block. A groove is formed in the front end of the polishing assembly. First sliding cavities are symmetrically formed in the portions, on the upper side and the lower side of the groove, of the polishing assembly. The side, away from the groove, of each first sliding cavity is provided with a second sliding cavity extending towards the right side in a communicating mode. Second thread rods extending left and right are arranged in the second sliding cavities. Pushing-pressing parts are connected to the second thread rods in a thread fit mode. The sides, close to the groove, of the inner walls on the right sides of the first sliding cavities are provided with limiting blocks. Lifting sliding blocks are connected to the interiors of the first sliding cavities in a sliding fit mode. The environment-friendly efficient steel pipe surface finishing and polishing device is simple in structure, convenient to mount and demount, high in polishing efficiency, capable of polishing steel pipes with different diameters and good in environmental protection effect.

Owner:JIANGSU LIWEI SHEARING & BENDING MACHINE

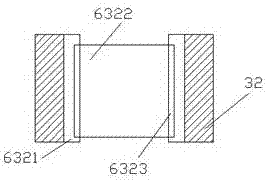

Spiral-thread rod component cleaning equipment

InactiveCN107303569AImprove cleaning efficiencySimple structureCleaning using liquidsSliding contactHelical coil

The invention discloses a spiral rod cleaning device, which comprises a base composed of a top beam and vertical bars fixed on the left and right bottoms of the top beam. A sliding groove is arranged in the end surface of the bottom of the top beam, and the sliding groove is provided with left and right The first screw rod is elongated, and the first screw rod is spirally connected with a sliding block. The bottom of the sliding block is equipped with a cleaning device. The front end of the cleaning device is equipped with a working tank. There is a first sliding joint cavity, and the first sliding joint cavity is provided with a second sliding joint cavity extending to the right on the side away from the working tank and penetrating with each other. The second sliding joint cavity is provided with a second screw rod extending left and right , the second screw rod is screw-fitted with a lower pressure block, the inner wall on the right side of the first sliding joint cavity is provided with a bump on the side of the working groove, and the vertical sliding joint block is connected with sliding joints in the first sliding joint cavity; the present invention The structure is simple, the installation and disassembly are convenient, and the cleaning efficiency is high, which can meet the cleaning work of rods with different diameters.

Owner:慈溪市隆诚贸易有限公司

Cleaning equipment

ActiveCN106925554AImprove cleaning efficiencySatisfy cleaning workCleaning using liquidsEngineeringMechanical engineering

Owner:日照市双驱机械制造有限公司

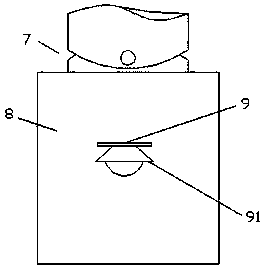

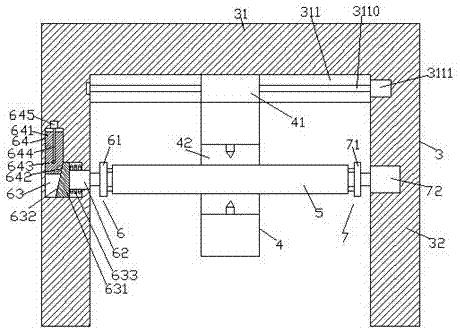

Steel pipe surface polishing and grinding device

InactiveCN108145574AImprove grinding efficiencySatisfy the grinding jobGrinding machinesGrinding work supportsMating connectionArchitectural engineering

The invention discloses a steel pipe surface polishing and grinding device. The steel pipe surface polishing and grinding device comprises a rack composed of a cross beam and supporting feet fixed tothe bottoms of the left side and the right side of the cross beam, a sliding groove is formed in the end face of the bottom of the cross beam, and a first threaded rod arranged in a left-right extending mode is arranged in the sliding groove; a sliding block is connected into the first threaded rod in a threaded fit mode, grinding assemblies are arranged at the bottom of the sliding block, a groove is formed in the front end of each grinding assembly, and first sliding cavities are symmetrically formed in the positions, on the upper sides and the lower sides of the grooves, of the grinding assemblies correspondingly; the sides, away from the grooves, of the first sliding cavities are provided with second sliding cavities which are formed in the mode of extending towards the right side, andthe first sliding cavities communicate with the second sliding cavities; second threaded rods arranged in a left-right extending mode are arranged in the second sliding cavities, and pushing pieces are connected to the second threaded rods in a threaded fit mode; limiting blocks are arranged on the sides, close to the grooves, of the inner walls of the right sides of the first sliding cavities; and lifting sliding blocks are connected into the first sliding cavities in a sliding fit mode. According to the steel pipe surface polishing and grinding device, the structure is simple, mounting anddismounting are convenient, the grinding efficiency is high, the grinding work for steel pipes with different diameters can be met, and the environmental protection effect is good.

Owner:宁波育闪科技有限公司

Environment-friendly and efficient steel tube surface polishing and grinding device

InactiveCN107877330AImprove grinding efficiencySatisfy the grinding jobGrinding carriagesGrinding drivesMating connectionEngineering

The invention discloses an environment-friendly and efficient steel tube surface polishing and grinding device. The polishing and grinding device includes a cross beam and a rack, wherein the rack iscomposed of supporting feet fixed on the bottom of both left and right sides of the cross beam. The end surface of the bottom of the cross beam is internally provided with a sliding groove. The sliding groove is provided with a first threaded rod arranged in left and right extending mode. The first threaded rod is internally connected with a sliding block in a threaded and matched mode. The bottomof the sliding block is provided with a polishing assembly. The front end of the polishing assembly is internally provided with a groove. Polishing assemblies on the upper and lower sides of the groove are internally provided with first sliding cavities symmetrically. A second sliding cavity arranged in an extending towards the right side mode is arranged on the side, away from the groove, of each first sliding cavity. Each first sliding cavity and the corresponding second sliding cavity communicate with each other. Each second sliding cavity is internally provided with a second threaded rodarranged in left and right extending mode. Each second threaded rod is connected with a pushing piece in a threaded and matched mode. The inner wall, close to the groove, of the right side of each first sliding cavity is provided with a limiting block. Each first sliding cavity is internally and slidably connected with a lifting sliding block in a matched mode. The environment-friendly and efficient steel tube surface polishing and grinding device is simple in structure, convenient to arrange and remove, and high in polishing efficiency; polishing of steel tubes with different diameters can besatisfied; and the environmental protection effect is good.

Owner:宁波育闪科技有限公司

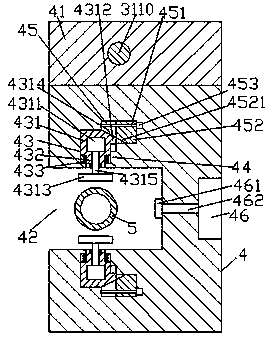

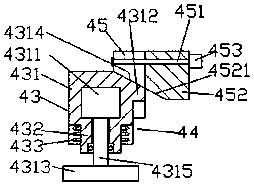

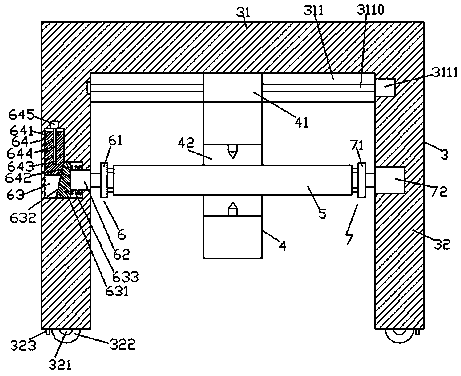

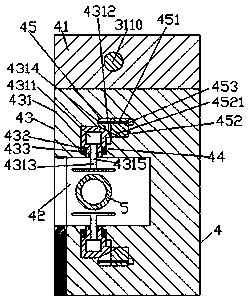

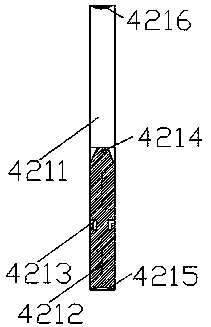

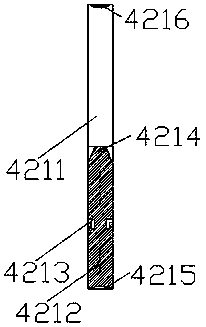

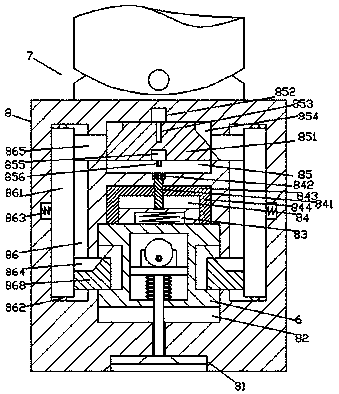

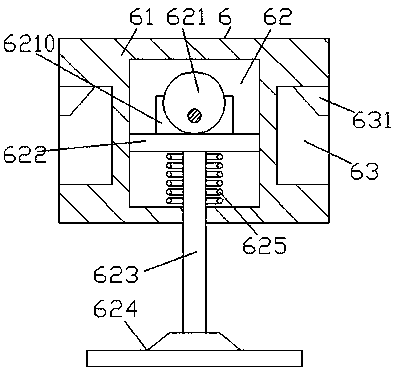

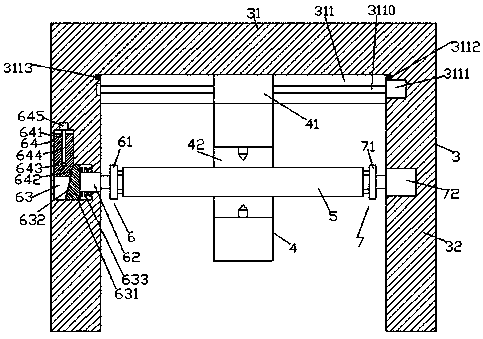

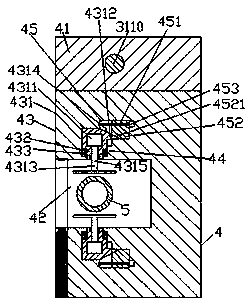

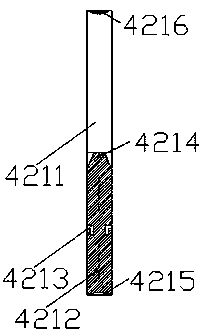

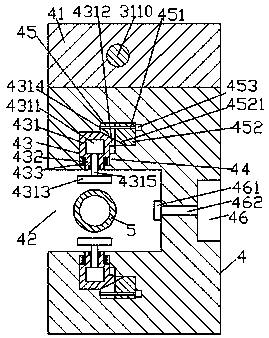

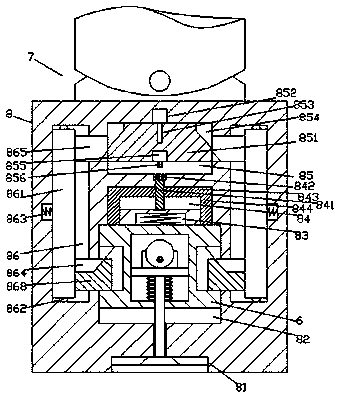

Forming device

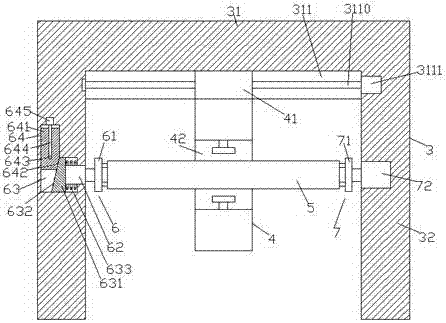

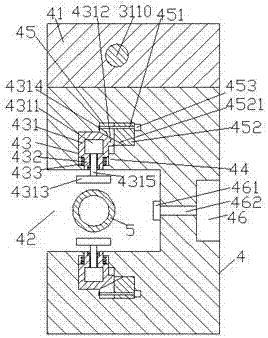

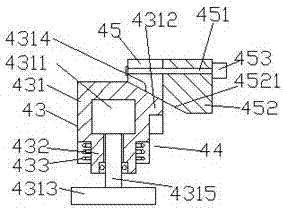

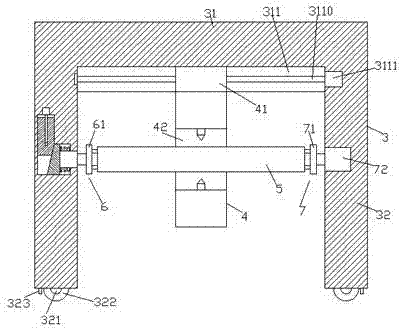

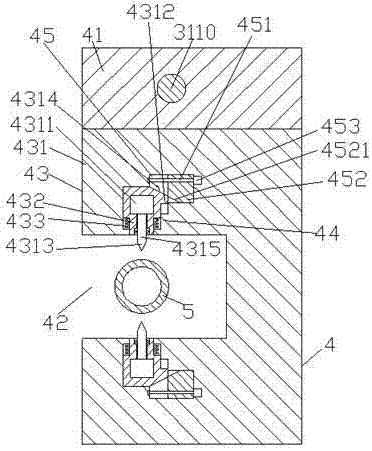

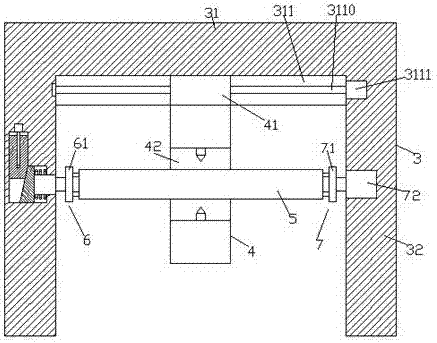

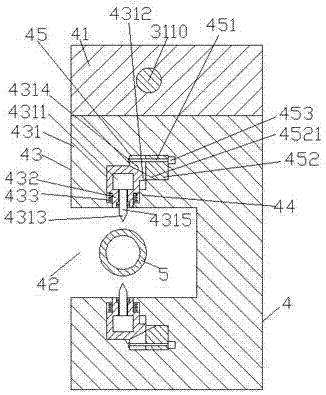

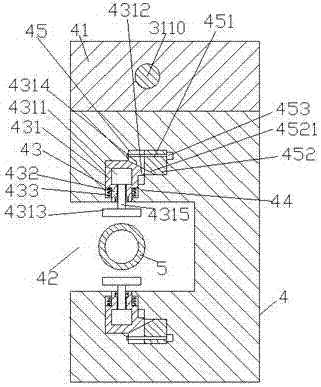

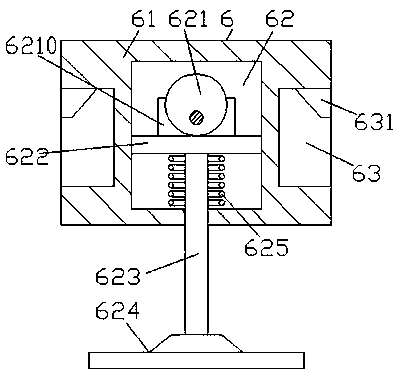

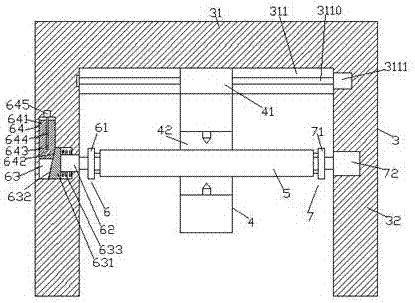

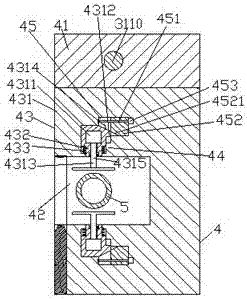

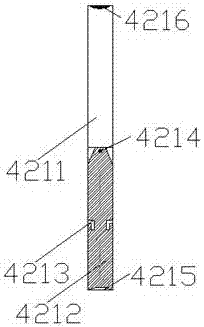

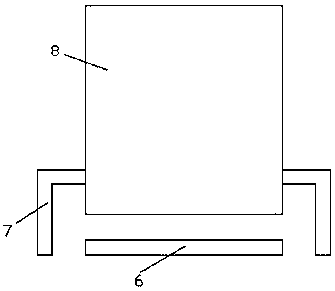

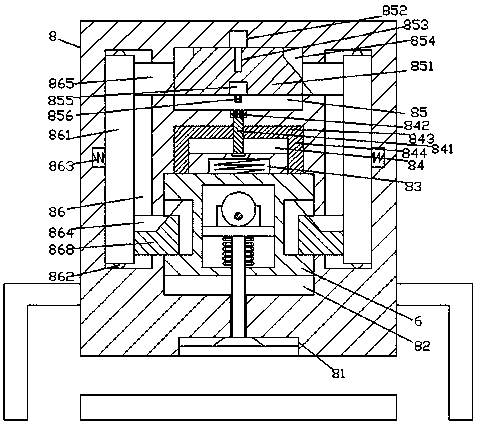

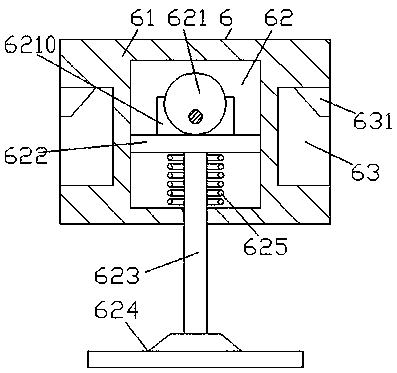

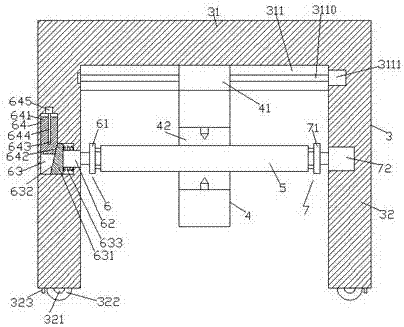

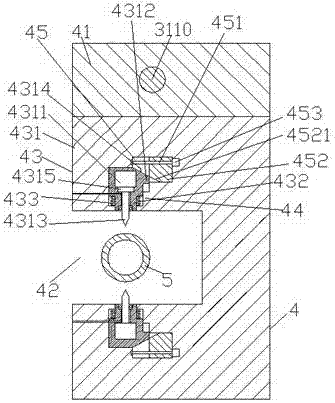

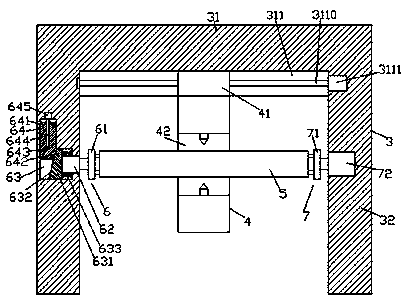

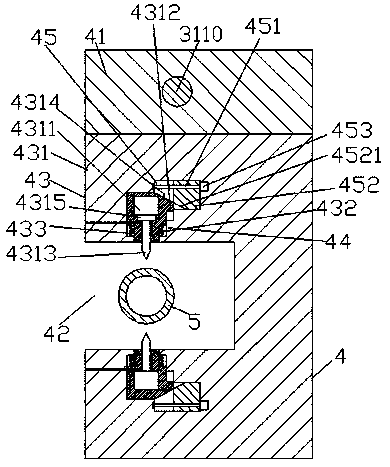

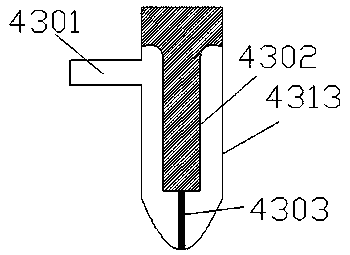

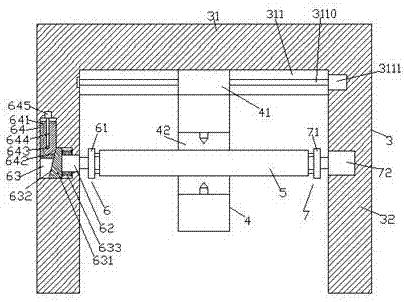

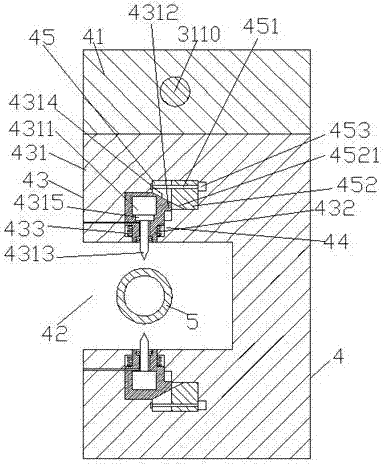

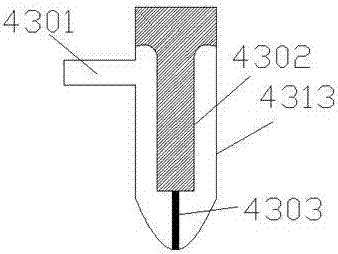

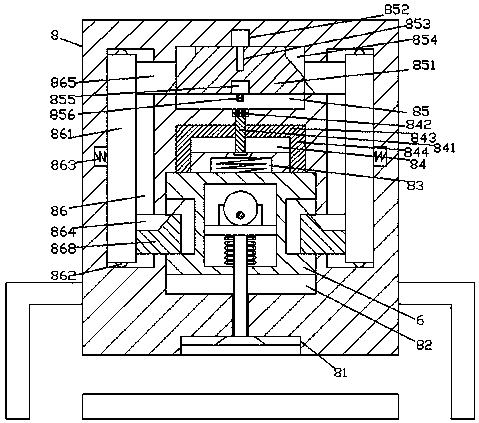

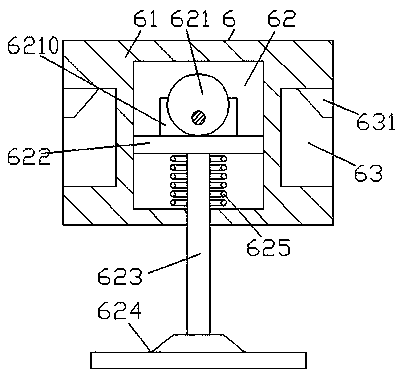

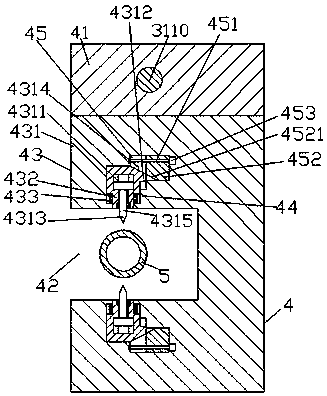

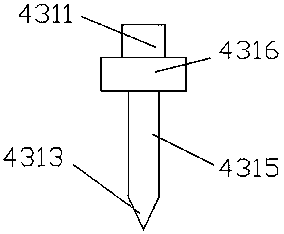

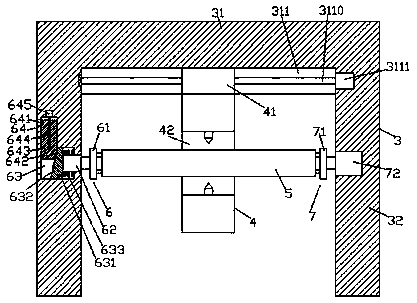

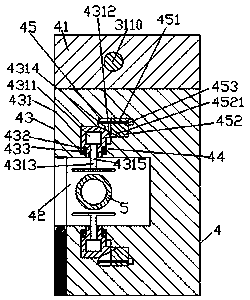

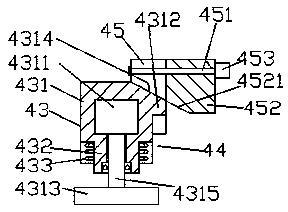

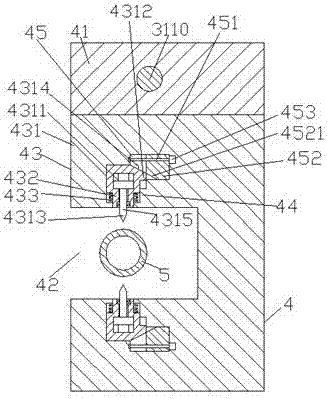

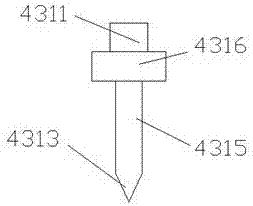

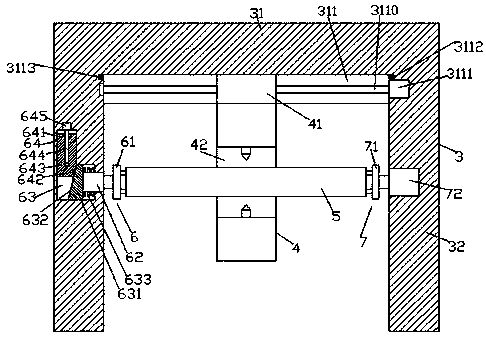

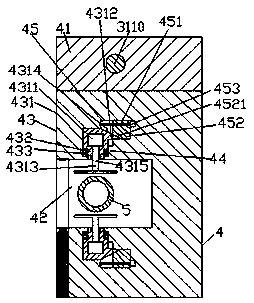

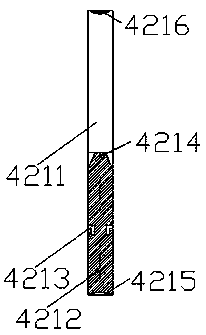

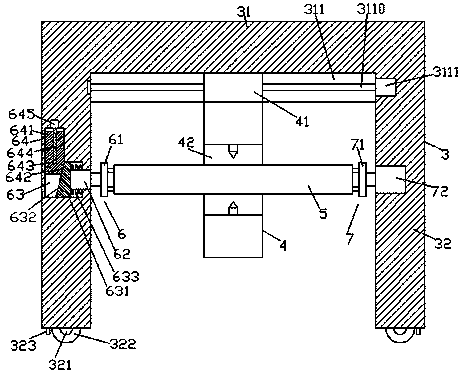

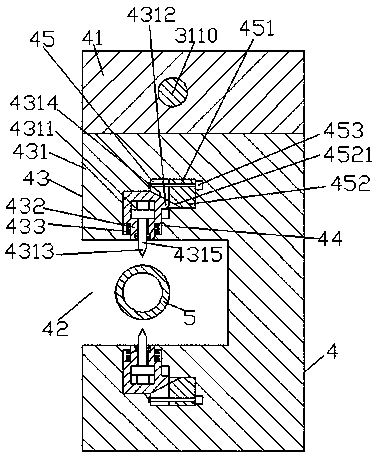

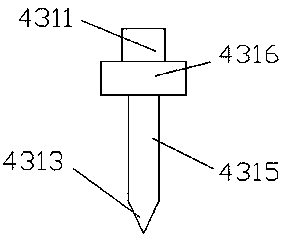

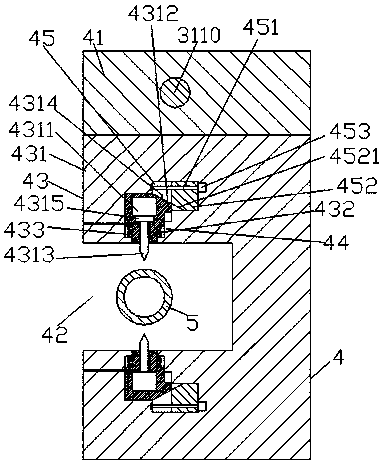

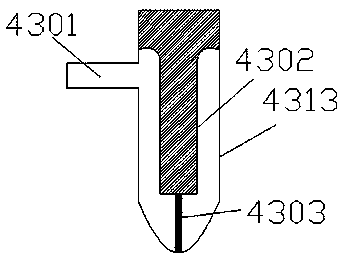

ActiveCN107030493AAutomatic control of telescopic workRealize high-precision processing adjustmentFeeding apparatusLarge fixed membersSteel columnsMechanical engineering

The invention discloses a forming device. The forming device comprises a base body composed of a top rod and machine columns fixed at the bottoms of the left side and the right side of the top rod. A sliding chute is formed in the end surface of the bottom of the top rod and is provided with a first screw rod which is arranged in a left-right extension mode; a sliding block is connected in the first screw rod in a matched mode, a machining device is arranged at the bottom of the sliding block, and an operation groove is formed in the front end of the machining device; first sliding cavities are formed in the positions, on the upper side and the lower side of the operation groove, of the machining device, and second sliding cavities extending rightwards are formed in the sides, away from the operation groove, of the first sliding cavities and communicate with the first sliding cavities; second screws arranged in a left-right extension mode are arranged inside the second sliding cavities and are connected to pushing slide blocks in a matched mode; and sliding limiting blocks are arranged on the sides, adjacent to the operation groove, of the inner walls of the right side of the first sliding cavities, and vertical sliding blocks are connected in the first sliding cavities in a sliding and matched mode. The forming device is simple in structure, convenient to assemble and disassemble, high in machining efficiency and capable of meeting the requirements of machining steel columns with different diameters.

Owner:TAIZHOU CHIJUN INTELLIGENT EQUIP CO LTD

Novel container cleaning equipment

InactiveCN108212998AAutomatic control of telescopic workReduce exposureHollow article cleaningButt jointArchitectural engineering

The invention discloses novel container cleaning equipment which comprises a frame. Supporting columns are fixedly mounted on the periphery of the bottom end face of the frame, and telescopic adjusting rods are movably mounted in the bottoms of the supporting columns. Bottom plates are fixedly mounted at the bottoms of the telescopic adjusting rods, and a counter bore is formed in the bottom end face of the frame. A telescopic groove is formed in the position, on the upper side of the counter bore, in the frame, and a cleaning device is in smooth and matched connection in the telescopic groove. The cleaning device comprises a telescopic block and a cleaning component arranged in the telescopic block, and concave holes are correspondingly formed in the left end face and the right end face of the telescopic block. A first oblique corner block is fixedly arranged on the inner top wall of each concave hole, and a first elastic strip in butt joint with the top end face of the telescopic block is arranged in the center in the inner top wall of the telescopic groove. A locking device is arranged at the position, on the upper side of the first elastic strip, in the inner wall of the frame,and a push device is arranged at the position, on the upper side of the locking device, in the inner wall of the frame. The novel container cleaning equipment is simple in structure and convenient tooperate, safety is improved, the service life of the equipment is prolonged, and cleaning stability is improved.

Owner:黄东卫

Convenient and rapid cleaning equipment

InactiveCN107309195AImprove cleaning efficiencySatisfy cleaning workCleaning using liquidsEngineeringSliding contact

The invention discloses a convenient cleaning device, which comprises a base composed of a top beam and vertical bars fixed on the left and right bottoms of the top beam. A sliding joint groove is arranged in the end surface of the bottom of the top beam, and the sliding joint groove is provided with left and right elongated The first screw rod is set, and the first screw rod is screw-fitted with a sliding joint block. The bottom of the sliding joint block is provided with a cleaning device. The front end of the cleaning device is provided with a working tank. The first sliding connection cavity, the first sliding connection cavity is provided with a second sliding connection cavity extending to the right side and penetrating with each other on the side away from the working tank. The second sliding connection cavity is provided with a second screw rod extending left and right. The upper part of the two screw rods is spirally connected with a lower pressure block, and the inner wall on the right side of the first sliding joint cavity is provided with a protrusion on the side of the working groove, and the first sliding joint cavity is connected with a vertical sliding joint block; the structure of the present invention is simple , easy installation and disassembly, high cleaning efficiency, and can meet the cleaning work of rods of different diameters.

Owner:慈溪市隆诚贸易有限公司

Cutting machine

ActiveCN107020415AImprove cutting efficiencySimple structureTube shearing machinesShearing machine accessoriesMechanical engineeringTransverse beam

The invention discloses a cutting machine which comprises a machine body. The machine body is composed of a transverse beam and bearing feet fixed to the bottoms of the left side and the right side of the transverse beam. A sliding groove is formed in the end face of the bottom of the transverse beam. The sliding groove is provided with a first screw rod extended left and right. A sliding block is connected to the interior of the first screw rod in a screw matched mode. The bottom of the sliding block is provided with a cutting device. A concave groove is formed in the front end of the cutting device. First sliding cavities are symmetrically formed in the portions, on the upper and lower sides of the concave groove, of the cutting device. The sides, away from the concave groove, of the first sliding cavities are provided with second sliding cavities in a run-through mode, wherein the second sliding cavities are extended rightwards. Second screw rods extended left and right are arranged in the second sliding cavities. Pushing blocks are connected to the second screw rods in a screw matched mode. The side, close to the concave groove, of the inner wall of the right side of the first sliding cavity is provided with a limiting block. An up-down sliding block is connected to the interior of the first sliding cavity in a sliding matched mode. The cutting machine is simple in structure, convenient to mount and demount, high in cutting efficiency and capable of cutting metal parts with different diameters.

Owner:山东太通再生资源有限公司

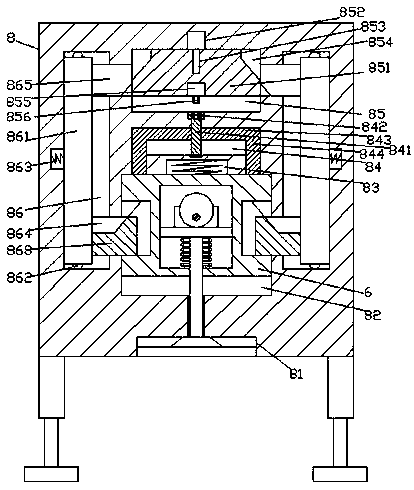

Environment-friendly board processing device

ActiveCN107627410AAutomatic control of telescopic workReduce exposurePlywood pressesControlling laminationEngineeringFlat panel

The invention discloses an environment-friendly board processing device. The device comprises a shell and foot stands fixedly installed on the left end face and the right end face of the shell; a placement flat plate is further arranged at the bottom end of the shell, and a certain gap is reserved between the placement flat plate and the end surface of the bottom of the shell; a sunken groove is formed in the end face of the bottom of the shell, a lifting groove is formed in the position, on the upper side the sunken groove, of the interior of the shell, and a pressing device is connected in the lifting groove in a sliding fit mode; and the pressing device comprises a lifting block and pressing components arranged in the lifting block, concave grooves are symmetrically formed in the end faces of the left side and the right side of the lifting block, a first inclined block is fixedly arranged on the inner top wall of each concave groove, and the middle end of the inner top wall of the lifting groove is internally provided with a first elastic piece which abuts against the top end face of the lifting block. According to the device, the structure is simple, the operation is convenient, the safety is improved, the service life of the device is prolonged, and the pressing stability is improved.

Owner:安徽福美达新材料科技有限公司

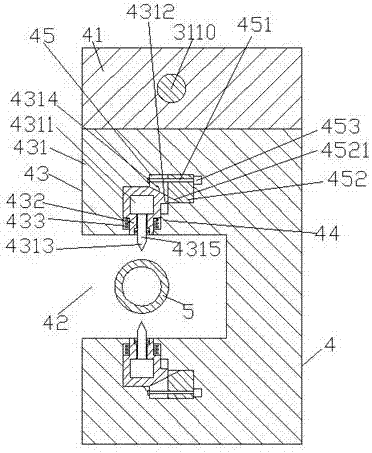

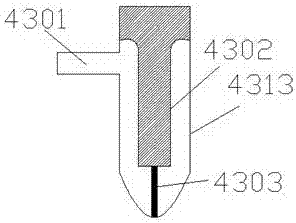

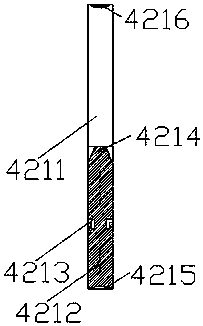

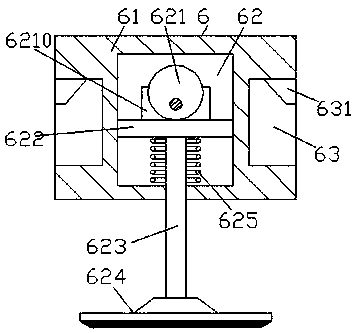

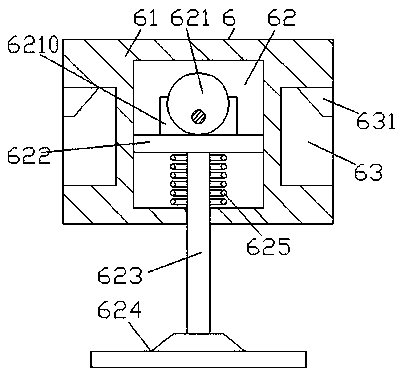

Pipe fitting welding device

ActiveCN107009083AImprove welding efficiencySatisfy welding workWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses a pipe fitting welding device. The pipe fitting welding device comprises a frame body composed of a cross rod and support legs fixed at the bottoms of the left side and the right side of the cross rod; a sliding groove is formed in the bottom end surface of the cross rod and is provided with a first spiral rod extending leftwards and rightwards; a sliding block is connected to the first spiral rod is in a spiral matched mode; a pipe fitting welding device body is arranged at the bottom of the sliding block; a sinking groove is formed in the front end of the pipe fitting welding device body; a first sliding cavity is correspondingly arranged at the position, at the upper side and the lower side of the sinking groove, in the pipe fitting welding device body; second sliding cavities extending rightwards are formed in the sides, away from the sinking groove, of the first sliding cavity and are connected; second spiral rods extending leftwards and rightwards are arranged in the second sliding cavities; push blocks are connected to the second spiral rods in the spiral matched mode; a limiting block is arranged on the side, close to the sinking groove, of the inner wall of the right side of the first sliding cavity; and a longitudinal sliding block is connected to the first sliding cavity in a sliding and matched mode. The pipe fitting welding device is simple in structure, convenient to install and disassemble, high in welding efficiency and capable of meeting the welding work of pipe fittings with different diameters.

Owner:江门市正汇金属制品有限公司

Metal part cutting machine

ActiveCN107855579AImplement rotary cuttingImprove cutting efficiencyTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a metal part cutting machine. The metal part cutting machine comprises a machine body, wherein the machine body is formed by a transverse beam and supporting legs fixed at thebottoms of the left side and the right side of the transverse beam. A sliding groove is formed in the end surface of the bottom of the transverse beam, the sliding groove is provided with a first screw rod which is arranged in a left-and-right extending mode, a sliding block is connected with the inner screw type of the first screw rod in a matched mode, and a cutting device is arranged at the bottom of the sliding block. A concave groove is formed in the front end of the cutting device, a first sliding cavity is arranged in the cutting device at the upper side and the lower side of the concave groove in a matched mode, a second sliding cavity extending towards the right side is formed in the side, far away from the sunken groove, of the first sliding cavity, a second screw rod which is arranged in a left-and-right extension mode is arranged in the second sliding cavity, the second screw rod is in screw-type fit connection with a pushing and extruding block, a limiting block is arranged on the side, close to the sunken groove, of the inner wall of the right side of the first sliding cavity, and an upper sliding block and a lower sliding block are arranged in the first sliding cavity in a sliding mode in a sliding mode. The metal part cutting device is simple in structure, convenient to mount and dismount, high in cutting efficiency and capable of meeting the cutting work of metal parts with different diameters.

Owner:润桐(苏州)技术服务有限公司

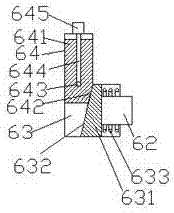

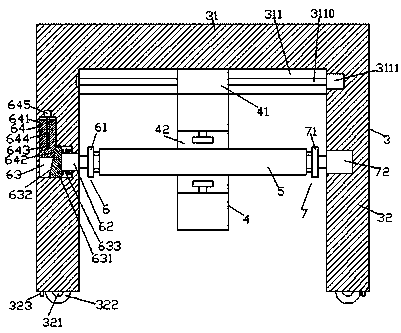

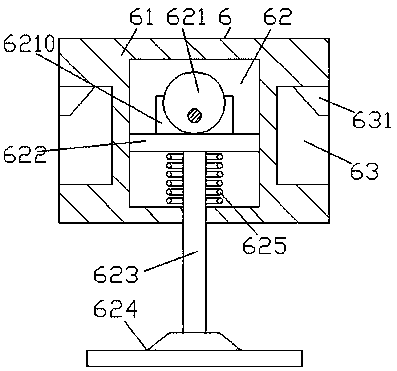

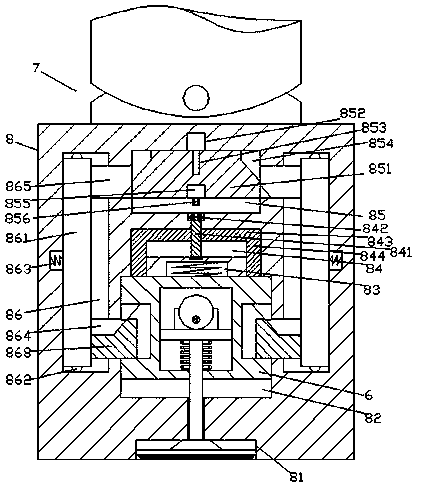

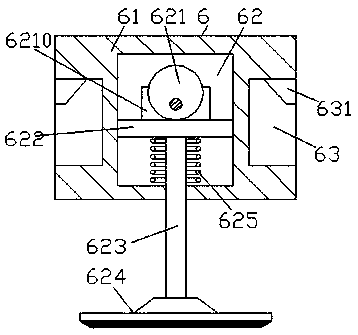

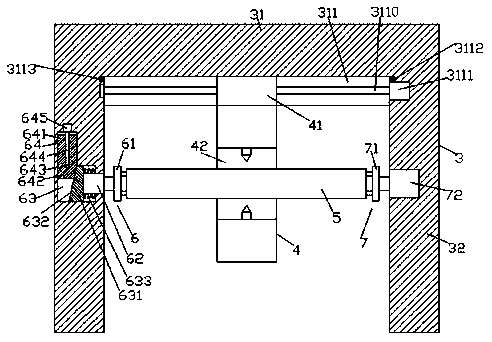

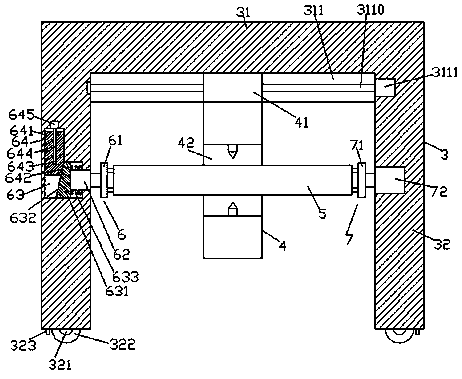

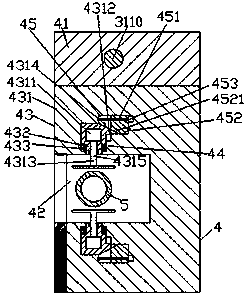

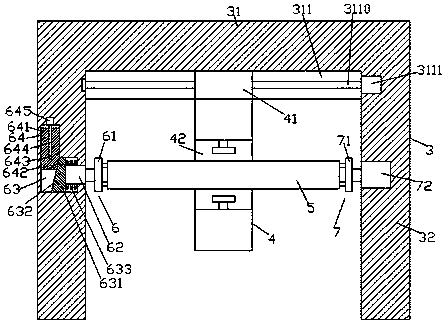

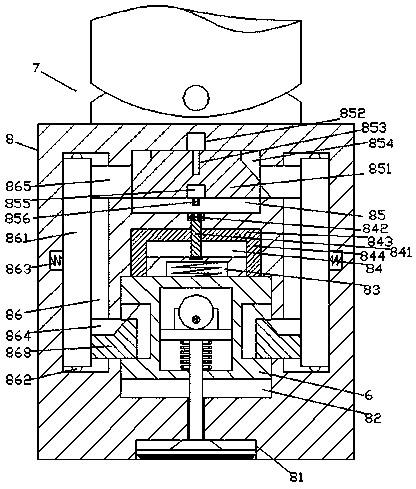

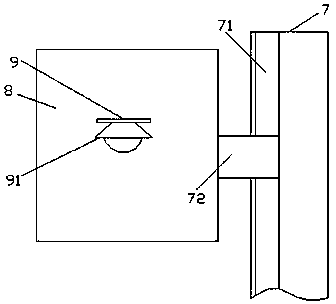

a welding device

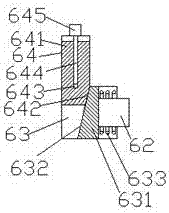

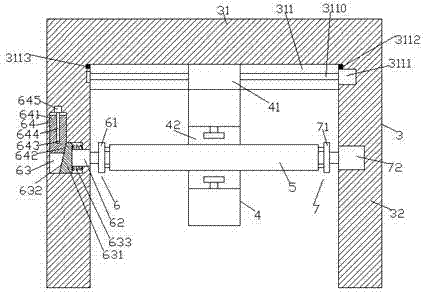

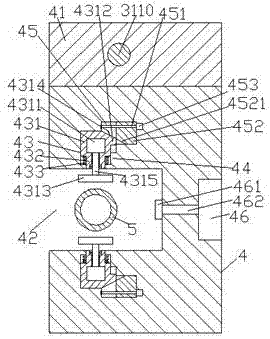

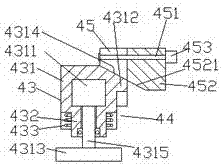

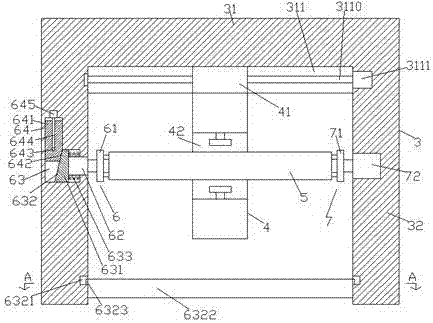

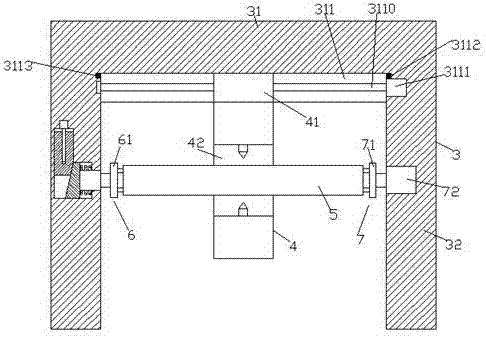

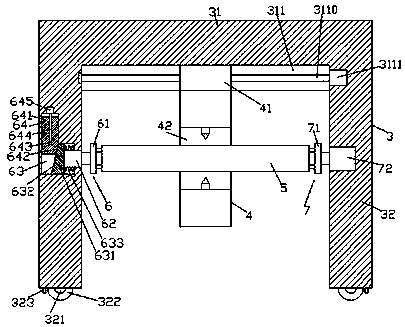

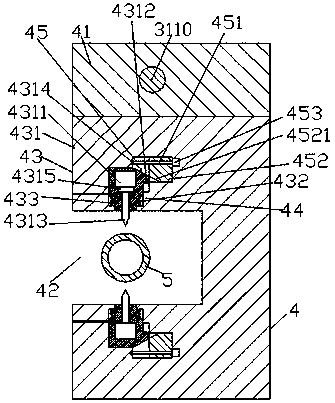

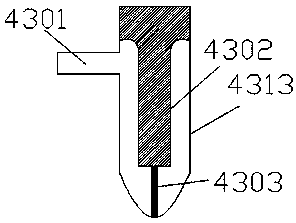

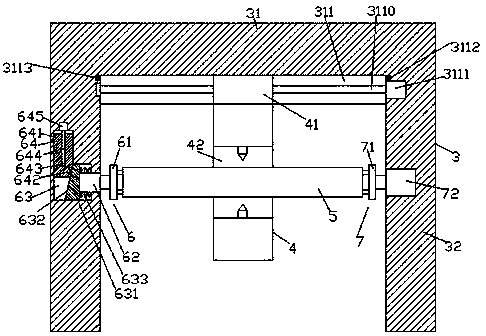

ActiveCN106944722BAutomatic control of telescopic workRealize high-precision welding adjustmentArc welding apparatusPipe fittingEngineering

The invention discloses a welding device. The welding device comprises a frame composed of a cross bar and supporting legs fixed to the bottoms of the left and right sides of the cross bar. A sliding groove is formed in the bottom end face of the cross bar. A first screw rod extending left and right is arranged in the sliding groove. A sliding block is connected into the first screw rod in a screw-thread fit mode. The bottom of the sliding block is provided with a welding device body. A countersunk groove is formed in the front end of the welding device body. A first sliding cavity is correspondingly formed in the part, on the upper and lower sides of the countersunk groove, of the welding device body. The side, far from the countersunk groove, of the first sliding cavity is provided with a second sliding cavity extending rightwards. The first sliding cavity communicates with the second sliding cavity. A second screw rod extending left and right is arranged in the second sliding cavity. A push block is connected to the second screw rod in a screw-thread fit mode. A limiting block is arranged on the side, close to the countersunk groove, of the inner wall of the right side of the first sliding cavity. A longitudinal sliding block is connected into the first sliding cavity in a sliding fit mode. The welding device is simple in structure, convenient to mount and demount, high in welding efficiency and capable of meeting the requirements for welding of pipe fittings with different diameters.

Owner:涡阳县康仕达机电有限公司

Welding device

The invention discloses a welding device. The welding device comprises a frame composed of a cross bar and supporting legs fixed to the bottoms of the left and right sides of the cross bar. A sliding groove is formed in the bottom end face of the cross bar. A first screw rod extending left and right is arranged in the sliding groove. A sliding block is connected into the first screw rod in a screw-thread fit mode. The bottom of the sliding block is provided with a welding device body. A countersunk groove is formed in the front end of the welding device body. A first sliding cavity is correspondingly formed in the part, on the upper and lower sides of the countersunk groove, of the welding device body. The side, far from the countersunk groove, of the first sliding cavity is provided with a second sliding cavity extending rightwards. The first sliding cavity communicates with the second sliding cavity. A second screw rod extending left and right is arranged in the second sliding cavity. A push block is connected to the second screw rod in a screw-thread fit mode. A limiting block is arranged on the side, close to the countersunk groove, of the inner wall of the right side of the first sliding cavity. A longitudinal sliding block is connected into the first sliding cavity in a sliding fit mode. The welding device is simple in structure, convenient to mount and demount, high in welding efficiency and capable of meeting the requirements for welding of pipe fittings with different diameters.

Owner:涡阳县康仕达机电有限公司

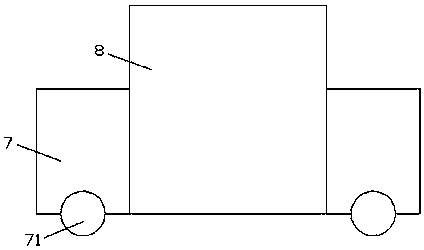

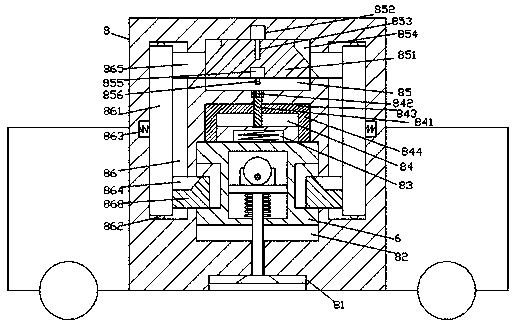

Novel garbage disposal device

InactiveCN108068376AAutomatic control of telescopic workReduce exposurePress ramCompression deviceEngineering

The invention discloses a novel garbage disposal device. The garbage disposal device comprises a traveling vehicle body and a seat body mounted in the traveling vehicle body; traveling wheels are mounted on the bottom end surface of the traveling vehicle body in a rolling manner; a sinking groove is formed in the bottom end surface of the seat body; a rising and falling cavity is formed in the seat body above the sinking groove; a compression device is connected in the rising and falling cavity in a movably matched manner and comprises a rising and falling frame and a compression element arranged in the rising and falling frame; concave grooves are equally formed in the end surfaces of the left side and the right side of the rising and falling frame; a first inclined-edge block is fixedlyarranged on the inner top wall of each concave groove; a first elastic pressing piece making contact with the top end surface of the rising and falling frame is arranged at the central point in the inner top wall of the rising and falling cavity; a locking connection device is arranged in the inner wall body of the seat body on the upper side of the first elastic pressing piece; and a pushing extruding device is arranged on the inner wall body of the seat body on the upper side of the locking connection device. The garbage disposal device is simple in structure and convenient to operate, the safety is improved, the service life of the garbage disposal device is further prolonged, and the compression stability is improved.

Owner:方安定

bridge construction equipment

ActiveCN107806017BAutomatic control of telescopic workReduce exposureBridge structural detailsBridge erection/assemblyArchitectural engineeringBuilding construction

Owner:安徽华井道科技服务有限公司

Novel environment-friendly plate machining device

InactiveCN108214715ASimple structureEasy to operatePlywood pressesLaminationEngineeringMechanical engineering

The invention discloses a novel environment-friendly plate machining device. The novel environment-friendly plate machining device comprises a shell and foot stools fixedly mounted on the left end face and the right end face of the shell. A placing slab is further arranged at the bottom end of the shell, and a certain clearance is reserved between the placing slab and the bottom end face of the shell. A sinking groove is formed in the bottom end face of the shell, and a lifting groove is formed in the position, on the upper side of the sinking groove, in the shell. A pressing device is in sliding and matched connection in the lifting groove, and comprises a lifting block and a pressing device arranged in the lifting block. Recessed grooves are symmetrically formed in the left end face andthe right end face of the lifting block, and a first oblique block is fixedly arranged on the inner top wall of each recessed groove. A first elastic part abutting against with the top end face of thelifting block is arranged at the middle end in the inner top wall of the lifting groove. The novel environment-friendly plate machining device is simple in structure and convenient to operate, safetyis improved, the service life of the equipment is prolonged, and pressing stability is improved.

Owner:黄鸿珊

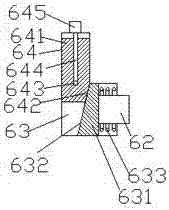

Improved paint spraying equipment

InactiveCN109225703AAutomatic control of telescopic workEasy to installLiquid spraying apparatusMating connectionEngineering

The invention discloses improved paint spraying equipment. The improved paint spraying equipment comprises a base frame, wherein the base frame is composed of an upper beam and stand bars fixed to thebottoms of the left side and the right side of the upper beam. A sliding conveying groove is formed in the bottom end face of the upper beam and provided with a left-right-extending first spiral rod.The first spiral rod is internally connected with a sliding conveying block in a threaded fit manner. A paint spraying device is arranged at the bottom of the sliding conveying block. A containing groove is formed in the front end of the paint spraying device. The parts, on the upper side and the lower side of the containing groove, of the paint spraying device are internally correspondingly provided with first sliding conveying cavities. The sides, away from the containing groove, of the first sliding conveying cavities are provided with second sliding conveying cavities extending towards the right side, and communication arrangement is achieved. Second spiral rods extending left and right are arranged in the second sliding conveying cavities. The second spiral rods are connected with ejector blocks in a threaded fit manner. The sides, adjacent to the containing groove, of the inner walls of the right sides of the first sliding conveying cavities are provided with clamping limiting blocks. The first sliding conveying cavities are internally connected with vertical sliding conveying blocks in a sliding conveying fit manner. The improved paint spraying equipment is simple in structure, convenient to mount and dismount, high in paint spraying efficiency and capable of achieving paint spraying work for workpieces different in diameter and size.

Owner:CIXI XINCHANG IND PROD DESIGN

a cutting machine

ActiveCN107020415BAutomatic control of telescopic workEasy to installTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a cutting machine which comprises a machine body. The machine body is composed of a transverse beam and bearing feet fixed to the bottoms of the left side and the right side of the transverse beam. A sliding groove is formed in the end face of the bottom of the transverse beam. The sliding groove is provided with a first screw rod extended left and right. A sliding block is connected to the interior of the first screw rod in a screw matched mode. The bottom of the sliding block is provided with a cutting device. A concave groove is formed in the front end of the cutting device. First sliding cavities are symmetrically formed in the portions, on the upper and lower sides of the concave groove, of the cutting device. The sides, away from the concave groove, of the first sliding cavities are provided with second sliding cavities in a run-through mode, wherein the second sliding cavities are extended rightwards. Second screw rods extended left and right are arranged in the second sliding cavities. Pushing blocks are connected to the second screw rods in a screw matched mode. The side, close to the concave groove, of the inner wall of the right side of the first sliding cavity is provided with a limiting block. An up-down sliding block is connected to the interior of the first sliding cavity in a sliding matched mode. The cutting machine is simple in structure, convenient to mount and demount, high in cutting efficiency and capable of cutting metal parts with different diameters.

Owner:山东太通再生资源有限公司

metal cutting machine

ActiveCN107855579BAutomatic control of telescopic workEasy to installTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a metal part cutting machine. The metal part cutting machine comprises a machine body, wherein the machine body is formed by a transverse beam and supporting legs fixed at thebottoms of the left side and the right side of the transverse beam. A sliding groove is formed in the end surface of the bottom of the transverse beam, the sliding groove is provided with a first screw rod which is arranged in a left-and-right extending mode, a sliding block is connected with the inner screw type of the first screw rod in a matched mode, and a cutting device is arranged at the bottom of the sliding block. A concave groove is formed in the front end of the cutting device, a first sliding cavity is arranged in the cutting device at the upper side and the lower side of the concave groove in a matched mode, a second sliding cavity extending towards the right side is formed in the side, far away from the sunken groove, of the first sliding cavity, a second screw rod which is arranged in a left-and-right extension mode is arranged in the second sliding cavity, the second screw rod is in screw-type fit connection with a pushing and extruding block, a limiting block is arranged on the side, close to the sunken groove, of the inner wall of the right side of the first sliding cavity, and an upper sliding block and a lower sliding block are arranged in the first sliding cavity in a sliding mode in a sliding mode. The metal part cutting device is simple in structure, convenient to mount and dismount, high in cutting efficiency and capable of meeting the cutting work of metal parts with different diameters.

Owner:青岛金宇成金属有限公司

Improved compaction construction device for water conservancy side slope

InactiveCN108221921AAutomatic control of telescopic workReduce exposureCoastlines protectionSoil preservationEngineeringBuilding construction

The invention discloses an improved compaction construction device for a water conservancy side slope. The improved compaction construction device comprises an angle regulator and a rammer compactor body arranged at the bottom of the angle regulator; a sunk groove is formed in the bottom end face of the rammer compactor body; a lifting sliding cavity is formed in the part, on the upper side of thesunk groove, of the rammer compactor body; the interior of the lifting sliding cavity is connected with a compaction driving mechanism in a sliding fit manner; the compaction driving mechanism comprises a lifting sliding block and a compaction actuating mechanism arranged in the lifting sliding block; groove parts are symmetrically arranged in the end faces of the left side and the right side ofthe lifting sliding block; a first oblique surface convex block is fixedly arranged at the inner top wall of each groove part; a first elastic piece part abutting against the top end face of the lifting sliding block is arranged in the middle in the inner top wall of the lifting sliding cavity; a locking mechanism is formed in the part, on the upper side of the first elastic piece part, of an inner wall body of the rammer compactor body; and a jacking-pressing and pushing-sliding driving mechanism is formed in the part, on the upper side of the locking mechanism, of the inner wall body of therammer compactor body. The improved compaction construction device is simple in structure, convenient to operate and convenient to move and carry, the safety is improved, the service life of the improved compaction construction device is prolonged, and the compaction stability is improved.

Owner:方媛媛

Novel cutting machine

ActiveCN107855584AImplement rotary cuttingImprove cutting efficiencyShearing machine accessoriesShearing toolsEngineeringMechanical engineering

The invention discloses a novel cutting machine. The novel cutting machine comprises a machine body, wherein the machine body is formed by a transverse beam and supporting legs fixed at the bottoms ofthe left side and the right side of the transverse beam. A sliding groove is formed in the end surface of the bottom of the transverse beam, the sliding groove is provided with a first screw rod which is arranged in a left-and-right extending mode, a sliding block is connected with the inner screw type of the first screw rod in a matched mode, and a cutting device is arranged at the bottom of thesliding block. A concave groove is formed in the front end of the cutting device, a first sliding cavity is arranged in the cutting device at the upper side and the lower side of the concave groove in a matched mode, a second sliding cavity extending towards the right side is formed in the side, far away from the sunken groove, of the first sliding cavity, a second screw rod which is arranged ina left-and-right extension mode is arranged in the second sliding cavity, the second screw rod is in screw-type fit connection with a pushing and extruding block, a limiting block is arranged on the side, close to the sunken groove, of the inner wall of the right side of the first sliding cavity, and an upper sliding block and a lower sliding block are arranged in the first sliding cavity in a sliding mode in a sliding mode. The novel cutting device is simple in structure, convenient to mount and dismount, high in cutting efficiency and capable of meeting the cutting work of metal parts with different diameters.

Owner:唐山森阳精密机械制造有限公司

A steel pipe surface polishing device

ActiveCN107052978BAutomatic control of telescopic workEasy to installPolishing machinesGrinding work supportsEngineeringSurface finishing

The invention discloses an environment-friendly efficient steel pipe surface finishing and polishing device. The device comprises a machine frame. The machine frame is composed of a cross beam and supporting feet fixed to the bottoms of the left side and the right side of the cross beam. A sliding groove is formed in the end face of the bottom of the cross beam. A first thread rod extending left and right is arranged in the sliding groove. A sliding block is connected to the interior of the first thread rod in a thread fit mode. A polishing assembly is arranged at the bottom of the sliding block. A groove is formed in the front end of the polishing assembly. First sliding cavities are symmetrically formed in the portions, on the upper side and the lower side of the groove, of the polishing assembly. The side, away from the groove, of each first sliding cavity is provided with a second sliding cavity extending towards the right side in a communicating mode. Second thread rods extending left and right are arranged in the second sliding cavities. Pushing-pressing parts are connected to the second thread rods in a thread fit mode. The sides, close to the groove, of the inner walls on the right sides of the first sliding cavities are provided with limiting blocks. Lifting sliding blocks are connected to the interiors of the first sliding cavities in a sliding fit mode. The environment-friendly efficient steel pipe surface finishing and polishing device is simple in structure, convenient to mount and demount, high in polishing efficiency, capable of polishing steel pipes with different diameters and good in environmental protection effect.

Owner:JIANGSU LIWEI SHEARING & BENDING MACHINE

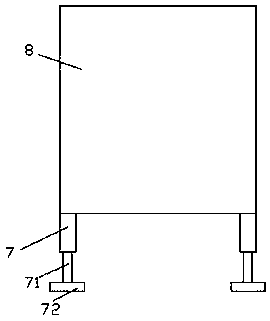

Bridge construction equipment

ActiveCN107806017AAutomatic control of telescopic workReduce exposureBridge structural detailsBridge erection/assemblyArchitectural engineeringBuilding construction

The invention discloses a set of bridge construction equipment. The equipment comprises an orientation debugger and a shell body arranged at the bottom of the orientation debugger. A sinking chamber is arranged in the end face of the bottom of the shell body, a lifting groove is formed in the shell body of the upper side of the sinking chamber, a compacting device is slidably and cooperatively connected in the lifting groove; the compacting device comprises a lifting block and a compacting component arranged in the lifting block, concave chambers are symmetrically arranged in the left and right end faces of the lifting block, first oblique blocks are fixedly arranged on the inner top walls of the concave chambers, a first elastic piece in butt connection with the top end face of the lifting block is arranged in the middle of the inner top wall of the lifting groove, a locking device is arranged in the inner wall body of the shell body of the upper side of the first elastic piece, anda thrusting device is arranged in the inner wall body of the shell body of the upper side of the locking device. The equipment is simple in structure and convenient to operate; the equipment improvessafety, prolongs service life of the equipment, and improves stability of compacting.

Owner:安徽华井道科技服务有限公司

Improved mailbox device

InactiveCN108209494ASimple structureEasy to operateKitchen equipmentDomestic articlesJoystickEngineering

The invention discloses an improved mailbox device, comprising the joystick and a frame that can be moved up and down and mounted on the joystick. The control rod is arranged with a dovetail slot withan opening to the left and an upper and lower opening, and a mounting plate is arranged in the dovetail slot for up and down translation. The left end surface of the mounting plate is fixedly connected with the outer frame, and the bottom end surface of the outer frame is arranged with a sinking hole, and the outer frame of the upper side of the sinking mouth is arranged with a contracting cavity, and the marking chamber is connected with a marking device. The marking device comprises a shrinking frame and a marking performing member arranged in the shrinking frame, and the notch is oppositely arranged in the left and right end faces of the shrinking frame; The device has the advantages of simple structure, convenient operation, improving safety and extending service life of the equipmentwith high marking stability.

Owner:黄恒锋

Lacquer spraying device

The invention discloses a painting equipment, which comprises a base frame composed of an upper beam and legs fixed on the left and right sides of the upper beam. A sliding groove is arranged in the end surface of the bottom of the upper beam. The sliding groove is provided with a left and right extending second A screw-shaped rod, the first screw-shaped rod is screw-fitted with a sliding block, the bottom of the sliding block is provided with a paint spraying device, the front end of the paint spraying device is provided with an accommodation groove, and the paint spraying devices on the upper and lower sides of the accommodation groove are correspondingly equipped with The first sliding cavity, the first sliding cavity is provided with a second sliding cavity extending to the right side and connected to the side far away from the receiving groove, and the second sliding cavity is provided with a second screw extending left and right A top block is screw-fitted on the second screw-shaped rod, and a stop block is provided on the right side of the inner wall of the first sliding chamber near the accommodation groove, and a vertical sliding block is connected to the first sliding chamber. block; the invention has simple structure, convenient installation and disassembly, high painting efficiency, and can meet the work of painting workpieces with different diameters.

Owner:CIXI XINCHANG IND PROD DESIGN

A new type of cutting machine

ActiveCN107855584BAutomatic control of telescopic workEasy to installShearing machine accessoriesShearing toolsEngineeringMechanical engineering

The invention discloses a novel cutting machine. The novel cutting machine comprises a machine body, wherein the machine body is formed by a transverse beam and supporting legs fixed at the bottoms ofthe left side and the right side of the transverse beam. A sliding groove is formed in the end surface of the bottom of the transverse beam, the sliding groove is provided with a first screw rod which is arranged in a left-and-right extending mode, a sliding block is connected with the inner screw type of the first screw rod in a matched mode, and a cutting device is arranged at the bottom of thesliding block. A concave groove is formed in the front end of the cutting device, a first sliding cavity is arranged in the cutting device at the upper side and the lower side of the concave groove in a matched mode, a second sliding cavity extending towards the right side is formed in the side, far away from the sunken groove, of the first sliding cavity, a second screw rod which is arranged ina left-and-right extension mode is arranged in the second sliding cavity, the second screw rod is in screw-type fit connection with a pushing and extruding block, a limiting block is arranged on the side, close to the sunken groove, of the inner wall of the right side of the first sliding cavity, and an upper sliding block and a lower sliding block are arranged in the first sliding cavity in a sliding mode in a sliding mode. The novel cutting device is simple in structure, convenient to mount and dismount, high in cutting efficiency and capable of meeting the cutting work of metal parts with different diameters.

Owner:唐山森阳精密机械制造有限公司

Workpiece paint spraying equipment

InactiveCN108787258AAutomatic control of telescopic workEasy to installSpraying apparatusEngineeringMechanical engineering

The invention discloses workpiece paint spraying equipment. The workpiece paint spraying equipment comprises a base frame, wherein the base frame is composed of an upper beam and stand bars fixed to the bottoms of the left side and the right side of the upper beam. A sliding conveying groove is formed in the bottom end face of the upper beam and provided with a left-right-extending first spiral rod. The first spiral rod is internally connected with a sliding conveying block in a threaded fit manner. A paint spraying device is arranged at the bottom of the sliding conveying block. A containinggroove is formed in the front end of the paint spraying device. The parts, on the upper side and the lower side of the containing groove, of the paint spraying device are internally correspondingly provided with first sliding conveying cavities. The sides, away from the containing groove, of the first sliding conveying cavities are provided with second sliding conveying cavities extending towardsthe right side, and communication arrangement is achieved. Second spiral rods extending left and right are arranged in the second sliding conveying cavities. The second spiral rods are connected withejector blocks in a threaded fit manner. The sides, adjacent to the containing groove, of the inner walls of the right sides of the first sliding conveying cavities are provided with clamping limitingblocks. The first sliding conveying cavities are internally connected with vertical sliding conveying blocks in a sliding conveying fit manner. The workpiece paint spraying equipment is simple in structure, convenient to mount and dismount, high in paint spraying efficiency and capable of achieving paint spraying work for workpieces different in diameter and size.

Owner:CIXI XINCHANG IND PROD DESIGN

A pipe fitting welding device

ActiveCN107009083BAutomatic control of telescopic workRealize high-precision welding adjustmentWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses a pipe fitting welding device. The pipe fitting welding device comprises a frame body composed of a cross rod and support legs fixed at the bottoms of the left side and the right side of the cross rod; a sliding groove is formed in the bottom end surface of the cross rod and is provided with a first spiral rod extending leftwards and rightwards; a sliding block is connected to the first spiral rod is in a spiral matched mode; a pipe fitting welding device body is arranged at the bottom of the sliding block; a sinking groove is formed in the front end of the pipe fitting welding device body; a first sliding cavity is correspondingly arranged at the position, at the upper side and the lower side of the sinking groove, in the pipe fitting welding device body; second sliding cavities extending rightwards are formed in the sides, away from the sinking groove, of the first sliding cavity and are connected; second spiral rods extending leftwards and rightwards are arranged in the second sliding cavities; push blocks are connected to the second spiral rods in the spiral matched mode; a limiting block is arranged on the side, close to the sinking groove, of the inner wall of the right side of the first sliding cavity; and a longitudinal sliding block is connected to the first sliding cavity in a sliding and matched mode. The pipe fitting welding device is simple in structure, convenient to install and disassemble, high in welding efficiency and capable of meeting the welding work of pipe fittings with different diameters.

Owner:江门市正汇金属制品有限公司

Electric welding device

InactiveCN108213660AImprove welding efficiencySatisfy welding workElectrode supporting devicesMating connectionPipe fitting

The invention discloses an electric welding device. The electric welding device comprises a frame composed of a transverse rod and supporting legs fixed to the bottoms of the left and right sides of the transverse rod. A sliding groove is formed in the end face of the bottom of the transverse rod. A first screw rod extending left and right is arranged in the sliding groove. A sliding block is in screw-thread fit with the first screw rod. An electric welding device body is arranged at the bottom of the sliding block. A sunken groove is formed in the front end of the electric welding device body. First sliding cavities are formed in the portions, located on the upper and lower sides of the sunken groove, of the electric welding device body correspondingly. A second sliding cavity extending rightwards and communicating with each first sliding cavity is formed in the side, far from the sunken groove, of the first sliding cavity. A second screw rod extending left and right is arranged in each second sliding cavity. A push block is connected to each second screw rod in a screw-thread fit mode. A limiting block is arranged on the side, close to the sunken groove, of each first sliding cavity. A longitudinal sliding block is connected to the interior of each first sliding cavity in a screw-thread fit mode. The electric welding device is simple in structure, convenient to install and dismantle, high in welding efficiency and capable of meeting the requirements for welding of pipe fittings with different diameters.

Owner:CIXI ZHIJIANG MECHANICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com