Improved compaction construction device for water conservancy side slope

A construction device and improved technology, applied in water conservancy engineering, marine engineering, soil protection and other directions, can solve the problems of uneven force, difficult movement and handling, poor slope compaction performance, etc., to improve safety and easy operation. , the effect of reducing exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

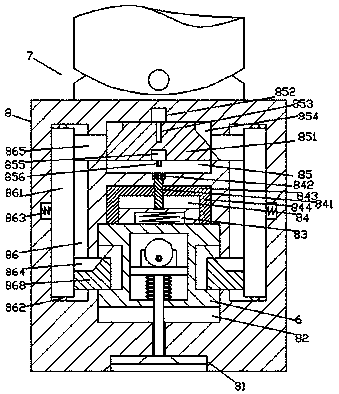

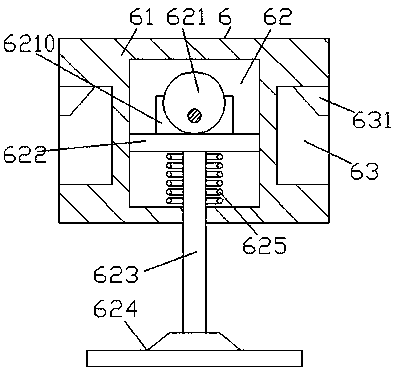

[0017] Such as Figure 1-Figure 6 As shown, an improved tamping construction device for water conservancy slopes of the present invention includes an angle adjuster 7 and a tamping body 8 installed at the bottom of the angle adjuster 7, and the bottom end surface of the tamping body 8 is provided with There is a sinking trough 81, and the tamping body 8 on the upper side of the sinking trough 81 is provided with a lifting sliding chamber 82, and a tamping driving mechanism 6 is slidably connected to the lifting sliding chamber 82, and the tamping driving mechanism 6 includes a lifting and lowering The slider 61 and the tamping actuator arranged in the lifting slider 61, the left and right sides of the lifting slider 61 are symmetrically provided with grooves 63, and the inner top wall of each groove 63 is A first inclined-plane protrusion 631 is fixedly provided, and a first elastic part 83 abutting against the top end surface of the lifting slider 61 is provided at a middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com