Cleaning equipment

A technology for cleaning equipment and cleaning devices, which is applied in the field of cleaning, can solve problems such as poor effect, low efficiency, and high labor intensity, and achieve the effects of improving cleaning efficiency, convenient installation and disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

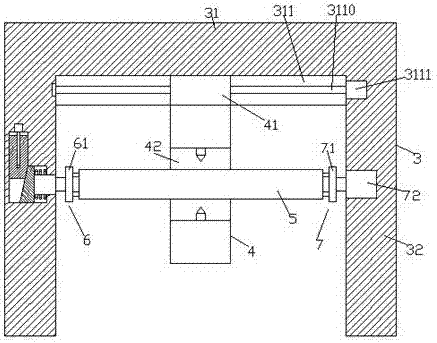

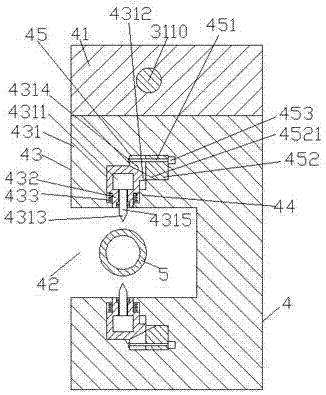

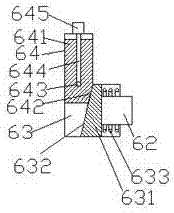

[0020] like figure 1 , figure 2 and image 3 As shown, a cleaning device of the present invention includes a substrate 3 composed of a top beam 31 and vertical rods 32 fixed on the left and right sides of the top beam 31, and a sliding groove is provided in the bottom end surface of the top beam 31 311, the sliding joint groove 311 is provided with a first screw rod 3110 extending left and right, the first screw rod 3110 is internally screwed and connected with a sliding joint block 41, and the bottom of the sliding joint block 41 is provided with a cleaning device 4 , the front end of the cleaning device 4 is provided with a working tank 42, and the cleaning device 4 on the upper and lower sides of the working tank 42 is oppositely provided with a first sliding joint cavity 43, and the first sliding joint cavity 43 is separated from the working tank One side of 42 is provided with a second sliding connection cavity 45 extending to the right side and passing through it. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com